Question: - - Question # 2 Fill in the blank - Using lab 5 , part 1 , scenario 1 , ensuring that the scenario is

Question # Fill in the blank Using lab part scenario ensuring that the scenario is reset, in order to get a total throughput of units, you would need to run the simulation for how Blank hours? Part I: Scenario One Understanding the Simulation System

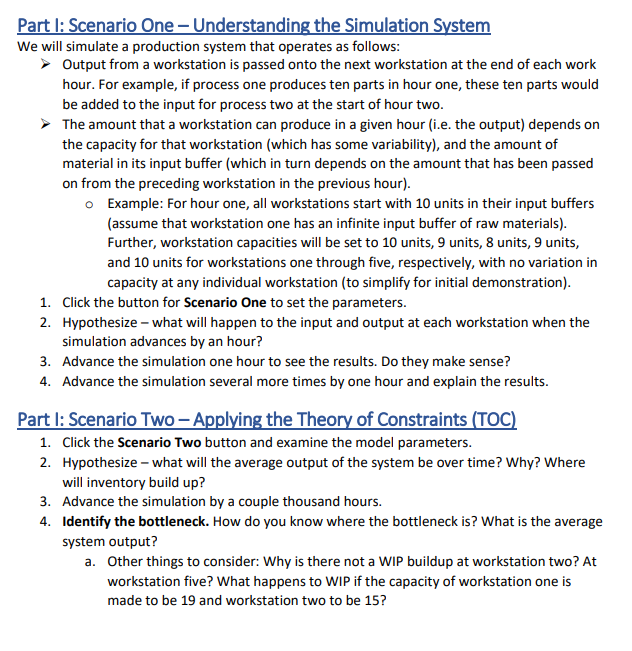

We will simulate a production system that operates as follows:

Output from a workstation is passed onto the next workstation at the end of each work

hour. For example, if process one produces ten parts in hour one, these ten parts would

be added to the input for process two at the start of hour two.

The amount that a workstation can produce in a given hour ie the output depends on

the capacity for that workstation which has some variability and the amount of

material in its input buffer which in turn depends on the amount that has been passed

on from the preceding workstation in the previous hour

Example: For hour one, all workstations start with units in their input buffers

assume that workstation one has an infinite input buffer of raw materials

Further, workstation capacities will be set to units, units, units, units,

and units for workstations one through five, respectively, with no variation in

capacity at any individual workstation to simplify for initial demonstration

Click the button for Scenario One to set the parameters.

Hypothesize what will happen to the input and output at each workstation when the

simulation advances by an hour?

Advance the simulation one hour to see the results. Do they make sense?

Advance the simulation several more times by one hour and explain the results.

Part I: Scenario Two Applying the Theory of Constraints TOC

Click the Scenario Two button and examine the model parameters.

Hypothesize what will the average output of the system be over time? Why? Where

will inventory build up

Advance the simulation by a couple thousand hours.

Identify the bottleneck. How do you know where the bottleneck is What is the average

system output?

a Other things to consider: Why is there not a WIP buildup at workstation two? At

workstation five? What happens to WIP if the capacity of workstation one is

made to be and workstation two to be

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock