Question: Question 2 Linear Programing Formulation (12 Points) X and Y Manufacturing would like to minimize the human power cost of producing machine motors for major

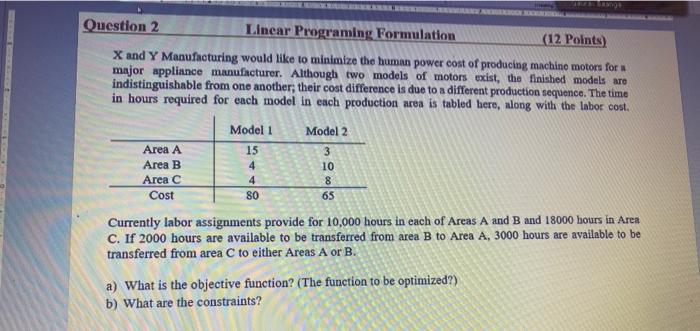

Question 2 Linear Programing Formulation (12 Points) X and Y Manufacturing would like to minimize the human power cost of producing machine motors for major appliance manufacturer. Although two models of motors exist, the finished models are indistinguishable from one another, their cost difference is due to a different production sequence. The time in hours required for each model in each production area is tabled here, along with the labor cost. Model 1 Area A Area B Area C Cost 15 4 4 80 Model 2 3 10 8 65 Currently labor assignments provide for 10,000 hours in each of Areas A and B and 18000 hours in Area C. If 2000 hours are available to be transferred from area B to Area A, 3000 hours are available to be transferred from area C to either Areas A or B. a) What is the objective function? (The function to be optimized?) b) What are the constraints

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts