Question: Question 3 ( 3 5 points ) . Larsen Pharmaceutical company has designed a batch process to create a crystalline API. On the benchtop, the

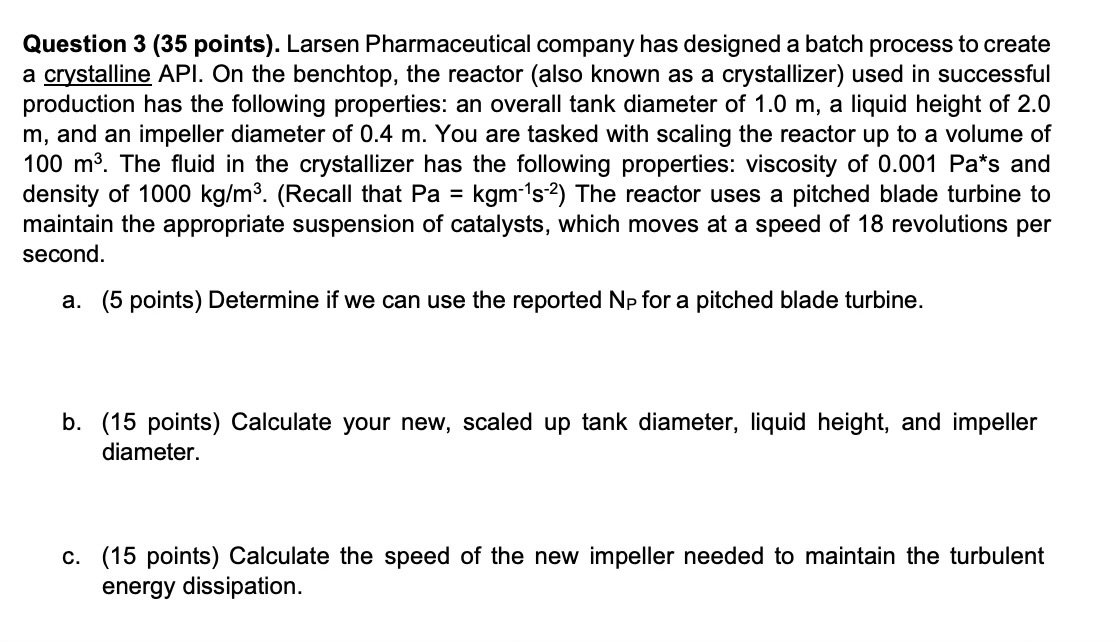

Question points Larsen Pharmaceutical company has designed a batch process to create a crystalline API. On the benchtop, the reactor also known as a crystallizer used in successful production has the following properties: an overall tank diameter of a liquid height of and an impeller diameter of You are tasked with scaling the reactor up to a volume of The fluid in the crystallizer has the following properties: viscosity of and density of Recall that The reactor uses a pitched blade turbine to maintain the appropriate suspension of catalysts, which moves at a speed of revolutions per second.

a points Determine if we can use the reported for a pitched blade turbine.

b points Calculate your new, scaled up tank diameter, liquid height, and impeller diameter.

c points Calculate the speed of the new impeller needed to maintain the turbulent energy dissipation.

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock