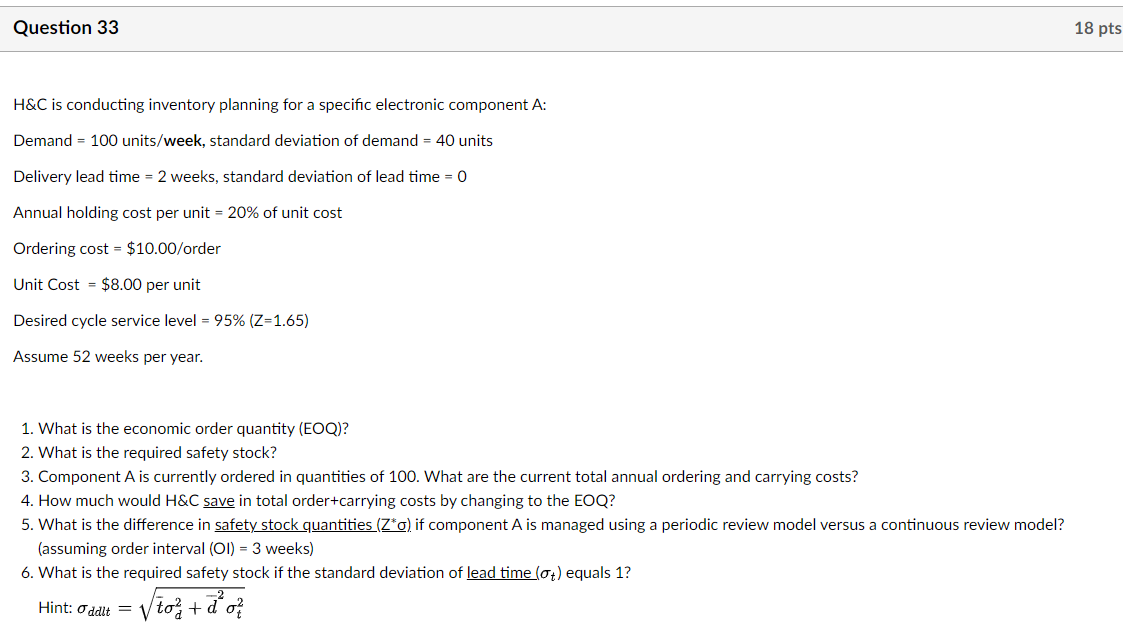

Question: Question 3 3 H & C is conducting inventory planning for a specific electronic component A : Demand = 1 0 0 units / week

Question

& is conducting inventory planning for a specific electronic component :

Demand unitsweek standard deviation of demand units

Delivery lead time weeks, standard deviation of lead time

Annual holding cost per unit of unit cost

Ordering cost $ order

Unit Cost $ per unit

Desired cycle service level

Assume weeks per year.

What is the economic order quantity EOQ

What is the required safety stock?

Component is currently ordered in quantities of What are the current total annual ordering and carrying costs?

How much would H&C save in total ordercarrying costs by changing to the EOQ?

What is the difference in safety stock quantities if component is managed using a periodic review model versus a continuous review model?

assuming order interval OI weeks

What is the required safety stock if the standard deviation of lead time equals

Hint:

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock