Question: QUESTION 4 (20 points) UMY machine shop has been in business for 27 years now and has only focused on three parts lately, namely Y2910,

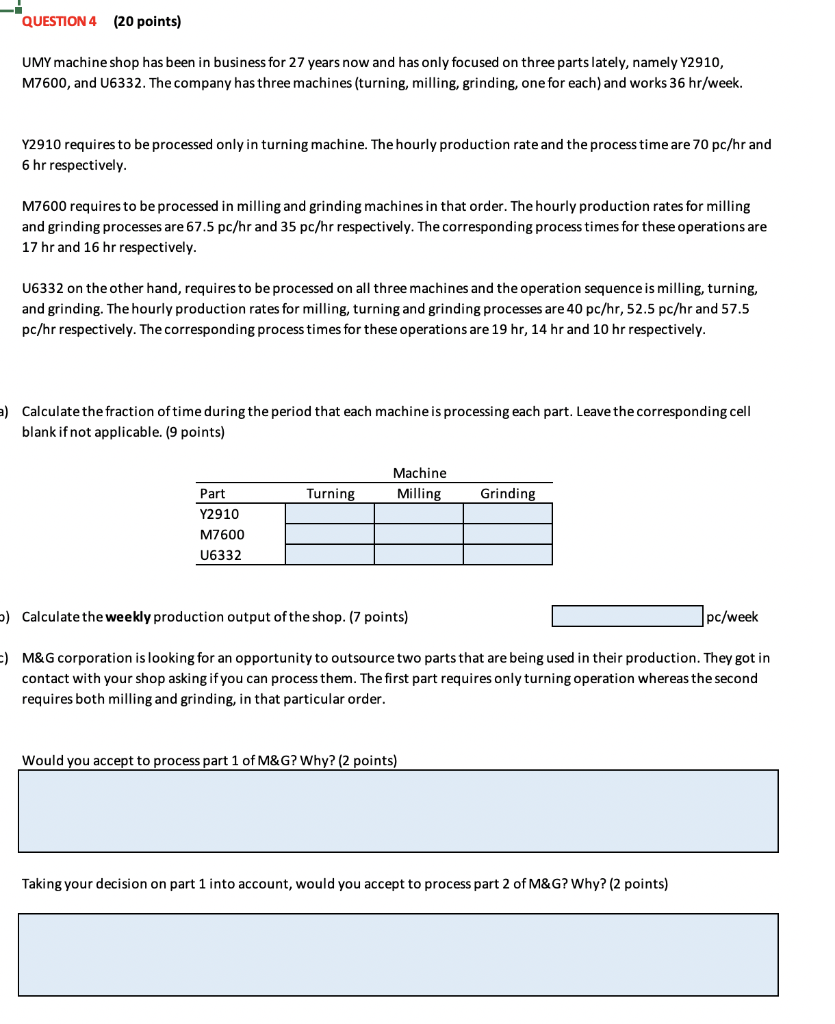

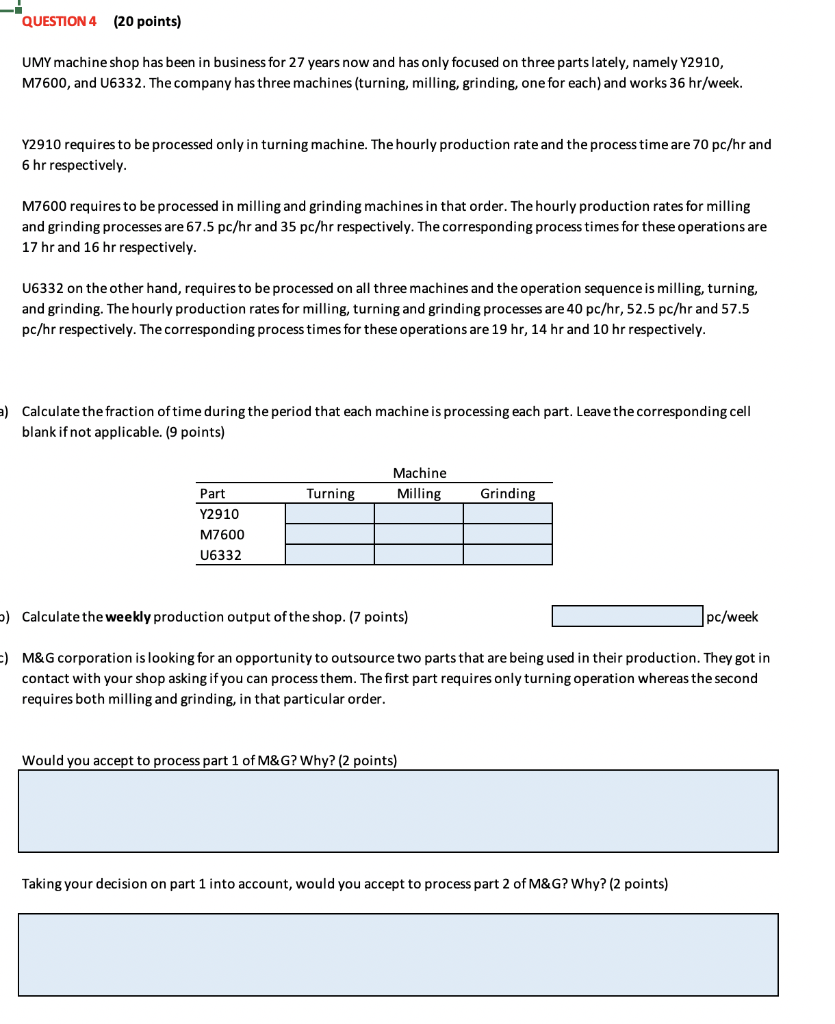

QUESTION 4 (20 points) UMY machine shop has been in business for 27 years now and has only focused on three parts lately, namely Y2910, M7600, and U6332. The company has three machines (turning, milling, grinding, one for each) and works 36 hr/week. Y2910 requires to be processed only in turning machine. The hourly production rate and the process time are 70 pc/hr and 6 hr respectively. M7600 requires to be processed in milling and grinding machines in that order. The hourly production rates for milling and grinding processes are 67.5 pc/hr and 35 pc/hr respectively. The corresponding process times for these operations are 17 hr and 16 hr respectively. U6332 on the other hand, requires to be processed on all three machines and the operation sequence is milling, turning, and grinding. The hourly production rates for milling, turning and grinding processes are 40 pc/hr, 52.5 pc/hr and 57.5 pc/hr respectively. The corresponding process times for these operations are 19 hr, 14 hr and 10 hr respectively. a) Calculate the fraction of time during the period that each machine is processing each part. Leave the corresponding cell blank if not applicable. (9 points) Machine Milling Turning Grinding Part Y2910 M7600 U6332 b) Calculate the weekly production output of the shop. (7 points) pc/week :) M&G corporation is looking for an opportunity to outsource two parts that are being used in their production. They got in contact with your shop asking if you can process them. The first part requires only turning operation whereas the second requires both milling and grinding, in that particular order. Would you accept to process part 1 of M&G? Why? (2 points) Taking your decision on part 1 into account, would you accept to process part 2 of M&G? Why? (2 points) QUESTION 4 (20 points) UMY machine shop has been in business for 27 years now and has only focused on three parts lately, namely Y2910, M7600, and U6332. The company has three machines (turning, milling, grinding, one for each) and works 36 hr/week. Y2910 requires to be processed only in turning machine. The hourly production rate and the process time are 70 pc/hr and 6 hr respectively. M7600 requires to be processed in milling and grinding machines in that order. The hourly production rates for milling and grinding processes are 67.5 pc/hr and 35 pc/hr respectively. The corresponding process times for these operations are 17 hr and 16 hr respectively. U6332 on the other hand, requires to be processed on all three machines and the operation sequence is milling, turning, and grinding. The hourly production rates for milling, turning and grinding processes are 40 pc/hr, 52.5 pc/hr and 57.5 pc/hr respectively. The corresponding process times for these operations are 19 hr, 14 hr and 10 hr respectively. a) Calculate the fraction of time during the period that each machine is processing each part. Leave the corresponding cell blank if not applicable. (9 points) Machine Milling Turning Grinding Part Y2910 M7600 U6332 b) Calculate the weekly production output of the shop. (7 points) pc/week :) M&G corporation is looking for an opportunity to outsource two parts that are being used in their production. They got in contact with your shop asking if you can process them. The first part requires only turning operation whereas the second requires both milling and grinding, in that particular order. Would you accept to process part 1 of M&G? Why? (2 points) Taking your decision on part 1 into account, would you accept to process part 2 of M&G? Why? (2 points)