Question: question 4 and 5 such that no machine runs more than 30 minutes longer that any other machine; assumitu that the milling operation is uniformly

question 4 and 5

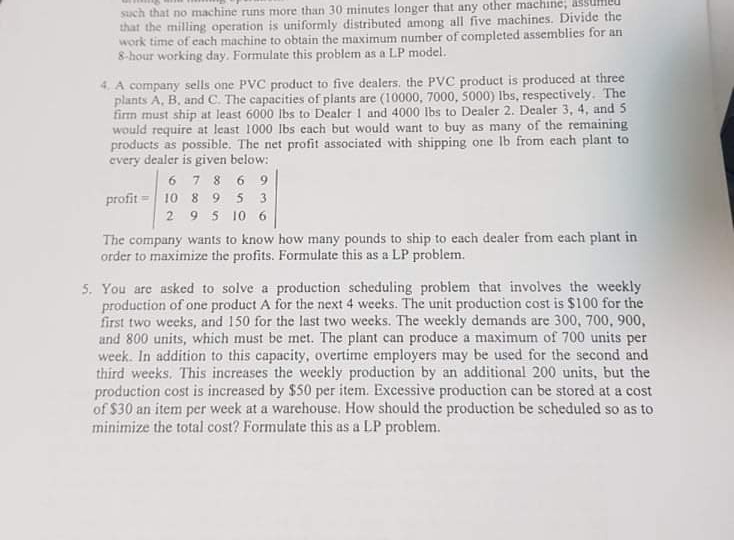

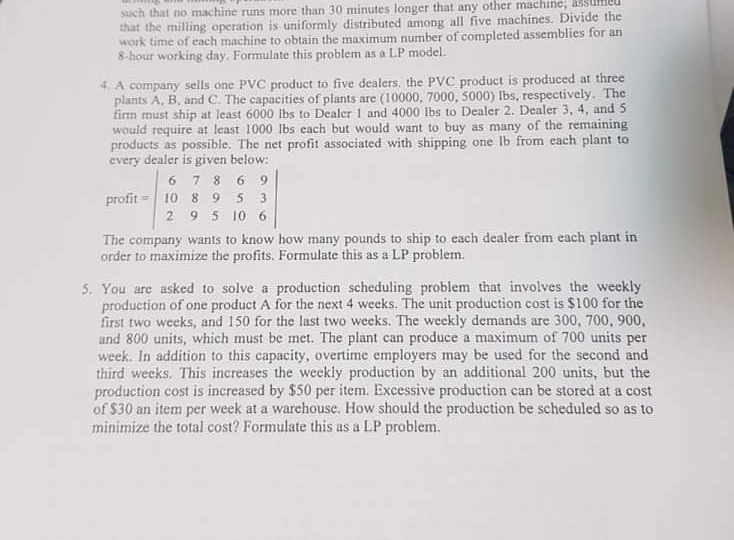

such that no machine runs more than 30 minutes longer that any other machine; assumitu that the milling operation is uniformly distributed among all five machines. Divide the work time of each machine to obtain the maximum number of completed assemblies for an 8-hour working day. Formulate this problem as a LP model. 4. A company sells one PVC product to five dealers, the PVC product is produced at three plants A, B and C. The capacities of plants are (10000, 7000, 5000) Ibs, respectively. The firm must ship at least 6000 lbs to Dealer 1 and 4000 lbs to Dealer 2. Dealer 3, 4, and 5 would require at least 1000 lbs cach but would want to buy as many of the remaining products as possible. The net profit associated with shipping one lb from each plant to every dealer is given below: 6 7 8 6 9 profit=108953 2 9 5 10 6 The company wants to know how many pounds to ship to each dealer from each plant in order to maximize the profits. Formulate this as a LP problem. 5. You are asked to solve a production scheduling problem that involves the weekly production of one product A for the next 4 weeks. The unit production cost is $100 for the first two weeks, and 150 for the last two weeks. The weekly demands are 300, 700, 900, and 800 units, which must be met. The plant can produce a maximum of 700 units per week. In addition to this capacity, overtime employers may be used for the second and third weeks. This increases the weekly production by an additional 200 units, but the production cost is increased by $50 per item. Excessive production can be stored at a cost of S30 an item per week at a warehouse. How should the production be scheduled so as to minimize the total cost? Formulate this as a LP problem. such that no machine runs more than 30 minutes longer that any other machine; assumitu that the milling operation is uniformly distributed among all five machines. Divide the work time of each machine to obtain the maximum number of completed assemblies for an 8-hour working day. Formulate this problem as a LP model. 4. A company sells one PVC product to five dealers, the PVC product is produced at three plants A, B and C. The capacities of plants are (10000, 7000, 5000) Ibs, respectively. The firm must ship at least 6000 lbs to Dealer 1 and 4000 lbs to Dealer 2. Dealer 3, 4, and 5 would require at least 1000 lbs cach but would want to buy as many of the remaining products as possible. The net profit associated with shipping one lb from each plant to every dealer is given below: 6 7 8 6 9 profit=108953 2 9 5 10 6 The company wants to know how many pounds to ship to each dealer from each plant in order to maximize the profits. Formulate this as a LP problem. 5. You are asked to solve a production scheduling problem that involves the weekly production of one product A for the next 4 weeks. The unit production cost is $100 for the first two weeks, and 150 for the last two weeks. The weekly demands are 300, 700, 900, and 800 units, which must be met. The plant can produce a maximum of 700 units per week. In addition to this capacity, overtime employers may be used for the second and third weeks. This increases the weekly production by an additional 200 units, but the production cost is increased by $50 per item. Excessive production can be stored at a cost of S30 an item per week at a warehouse. How should the production be scheduled so as to minimize the total cost? Formulate this as a LP

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock