Question: Question 4 The Production Manager and the Purchasing Manager have both agreed to adopt an inventory policy to be implemented for a critical chip CHIPX.

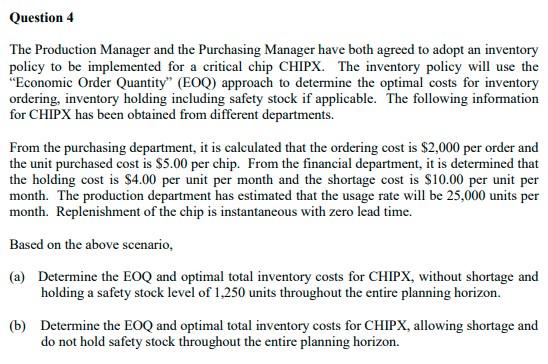

Question 4 The Production Manager and the Purchasing Manager have both agreed to adopt an inventory policy to be implemented for a critical chip CHIPX. The inventory policy will use the "Economic Order Quantity" (EOQ) approach to determine the optimal costs for inventory ordering, inventory holding including safety stock if applicable. The following information for CHIPX has been obtained from different departments. From the purchasing department, it is calculated that the ordering cost is $2,000 per order and the unit purchased cost is $5.00 per chip. From the financial department, it is determined that the holding cost is $4.00 per unit per month and the shortage cost is $10.00 per unit per month. The production department has estimated that the usage rate will be 25,000 units per month. Replenishment of the chip is instantaneous with zero lead time. Based on the above scenario, (a) Determine the EOQ and optimal total inventory costs for CHIPX, without shortage and holding a safety stock level of 1,250 units throughout the entire planning horizon. (b) Determine the EOQ and optimal total inventory costs for CHIPX, allowing shortage and do not hold safety stock throughout the entire planning horizon. () Would the Purchasing Manager consider buying at quantity discount based on the following costs and quantities considerations? $5.00 per unit from purchase quantity, O to 10,000 units $4.50 per unit from purchase quantity, 10,001 to 20,000 units $4.00 per unit from purchase quantity, 20,001 to 50,000 units Show the calculations on how the Purchasing Manager would evaluate the offer and what is the quantity to buy? (d) Explain the importance of accurate inventory records for MRP system in the determination of planned orders released. (e) If chip CHIPX is classified as an "A" item, what type of inventory control system and policy would be most appropriate and why? Question 4 The Production Manager and the Purchasing Manager have both agreed to adopt an inventory policy to be implemented for a critical chip CHIPX. The inventory policy will use the "Economic Order Quantity" (EOQ) approach to determine the optimal costs for inventory ordering, inventory holding including safety stock if applicable. The following information for CHIPX has been obtained from different departments. From the purchasing department, it is calculated that the ordering cost is $2,000 per order and the unit purchased cost is $5.00 per chip. From the financial department, it is determined that the holding cost is $4.00 per unit per month and the shortage cost is $10.00 per unit per month. The production department has estimated that the usage rate will be 25,000 units per month. Replenishment of the chip is instantaneous with zero lead time. Based on the above scenario, (a) Determine the EOQ and optimal total inventory costs for CHIPX, without shortage and holding a safety stock level of 1,250 units throughout the entire planning horizon. (b) Determine the EOQ and optimal total inventory costs for CHIPX, allowing shortage and do not hold safety stock throughout the entire planning horizon. () Would the Purchasing Manager consider buying at quantity discount based on the following costs and quantities considerations? $5.00 per unit from purchase quantity, O to 10,000 units $4.50 per unit from purchase quantity, 10,001 to 20,000 units $4.00 per unit from purchase quantity, 20,001 to 50,000 units Show the calculations on how the Purchasing Manager would evaluate the offer and what is the quantity to buy? (d) Explain the importance of accurate inventory records for MRP system in the determination of planned orders released. (e) If chip CHIPX is classified as an "A" item, what type of inventory control system and policy would be most appropriate and why

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts