Question: A particular machine has a loading time of 150 hours in a particular 7 day period. Changeovers and set-ups take an average of 15

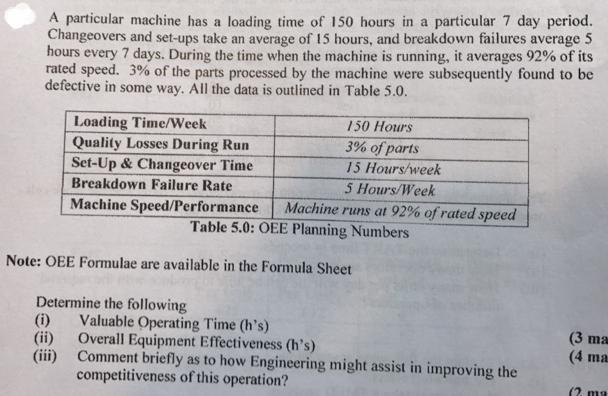

A particular machine has a loading time of 150 hours in a particular 7 day period. Changeovers and set-ups take an average of 15 hours, and breakdown failures average 5 hours every 7 days. During the time when the machine is running, it averages 92% of its rated speed. 3% of the parts processed by the machine were subsequently found to be defective in some way. All the data is outlined in Table 5.0. Loading Time/Week Quality Losses During Run Set-Up & Changeover Time Breakdown Failure Rate 150 Hours 3% of parts 15 Hours/week 5 Hours/Week Machine runs at 92% of rated speed Machine Speed/Performance Table 5.0: OEE Planning Numbers Note: OEE Formulae are available in the Formula Sheet Determine the following (i) Valuable Operating Time (h's) (3 ma (ii) Overall Equipment Effectiveness (h's) (4 ma (ii) Comment briefly as to how Engineering might assist in improving the competitiveness of this operation? (2 ma

Step by Step Solution

3.45 Rating (168 Votes )

There are 3 Steps involved in it

Answer i Calculate operating time as shown below Operating ti... View full answer

Get step-by-step solutions from verified subject matter experts