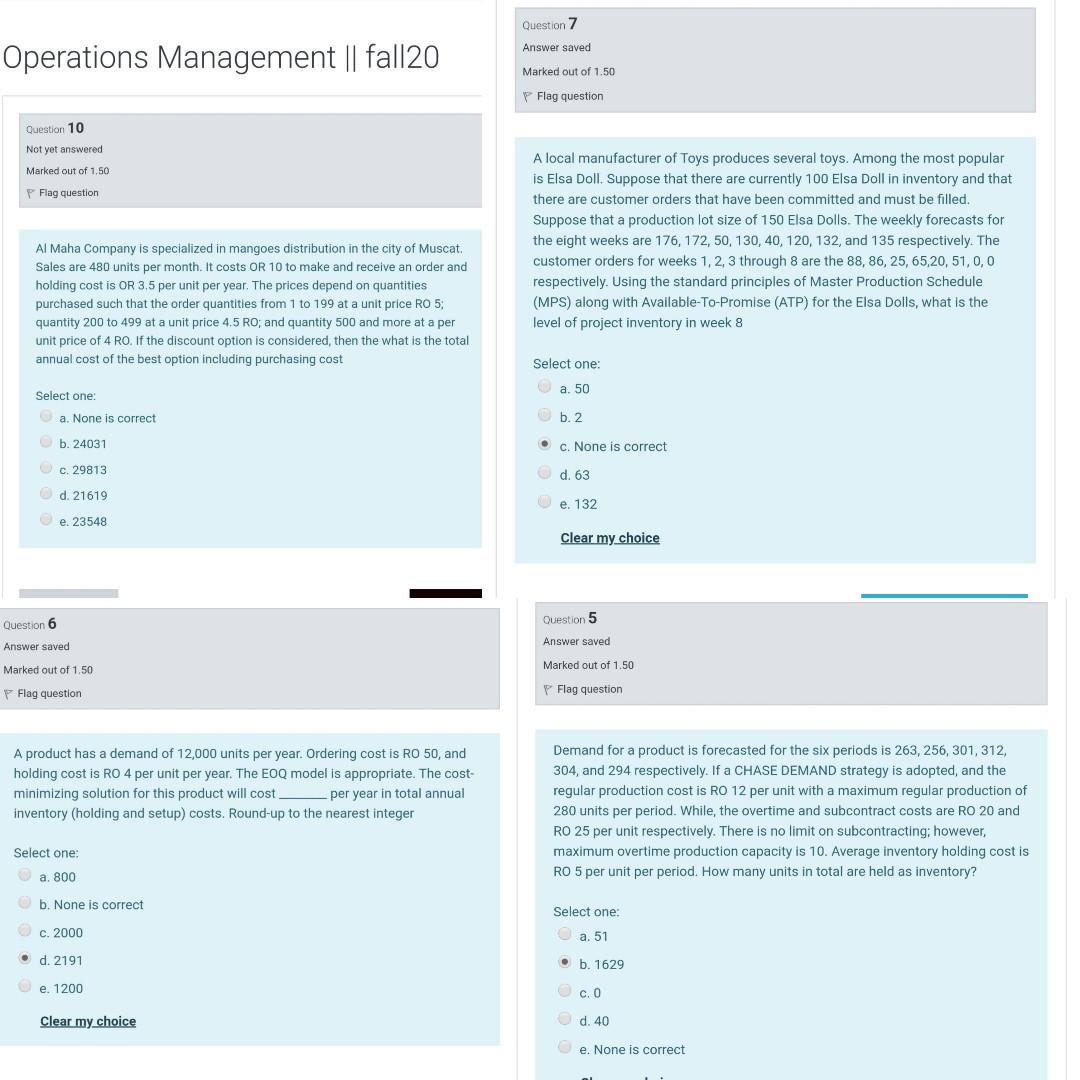

Question: Question 7 Answer saved Operations Management || fall20 Marked out of 1.50 P Flag question Question 10 Not yet answered Marked out of 1.50 P

Question 7 Answer saved Operations Management || fall20 Marked out of 1.50 P Flag question Question 10 Not yet answered Marked out of 1.50 P Flag question Al Maha Company is specialized in mangoes distribution in the city of Muscat. Sales are 480 units per month. It costs OR 10 to make and receive an order and holding cost is OR 3.5 per unit per year. The prices depend on quantities purchased such that the order quantities from 1 to 199 at a unit price RO 5; quantity 200 to 499 at a unit price 4,5 RO; and quantity 500 and more at a per unit price of 4 RO. If the discount option is considered, then the what is the total annual cost of the best option including purchasing cost A local manufacturer of Toys produces several toys. Among the most popular is Elsa Doll. Suppose that there are currently 100 Elsa Doll in inventory and that there are customer orders that have been committed and must be filled. Suppose that a production lot size of 150 Elsa Dolls. The weekly forecasts for the eight weeks are 176, 172, 50, 130, 40, 120, 132, and 135 respectively. The customer orders for weeks 1, 2, 3 through 8 are the 88, 86, 25, 65,20, 51,0,0 respectively. Using the standard principles of Master Production Schedule (MPS) along with Available-To-Promise (ATP) for the Elsa Dolls, what is the level of project inventory in week 8 Select one: a. 50 Select one: a. None is correct b.2 b. 24031 c. None is correct c. 29813 d. 63 d. 21619 e. 132 e. 23548 Clear my choice Question 6 Question 5 Answer saved Answer saved Marked out of 1.50 Marked out of 1.50 Flag question P Flag question A product has a demand of 12,000 units per year. Ordering cost is RO 50, and holding cost is RO 4 per unit per year. The EOQ model is appropriate. The cost- minimizing solution for this product will cost per year in total annual inventory (holding and setup) costs. Round-up to the nearest Integer Demand for a product is forecasted for the six periods is 263, 256, 301, 312, 304, and 294 respectively. If a CHASE DEMAND strategy is adopted, and the regular production cost is RO 12 per unit with a maximum regular production of 280 units per period. While, the overtime and subcontract costs are RO 20 and RO 25 per unit respectively. There is no limit on subcontracting; however, maximum overtime production capacity is 10. Average inventory holding cost is RO 5 per unit per period. How many units in total are held as inventory? Select one: a. 800 b. None is correct Select one: C. 2000 a. 51 . d. 2191 b. 1629 e. 1200 c.0 Clear my choice d. 40 e. None is correct

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock