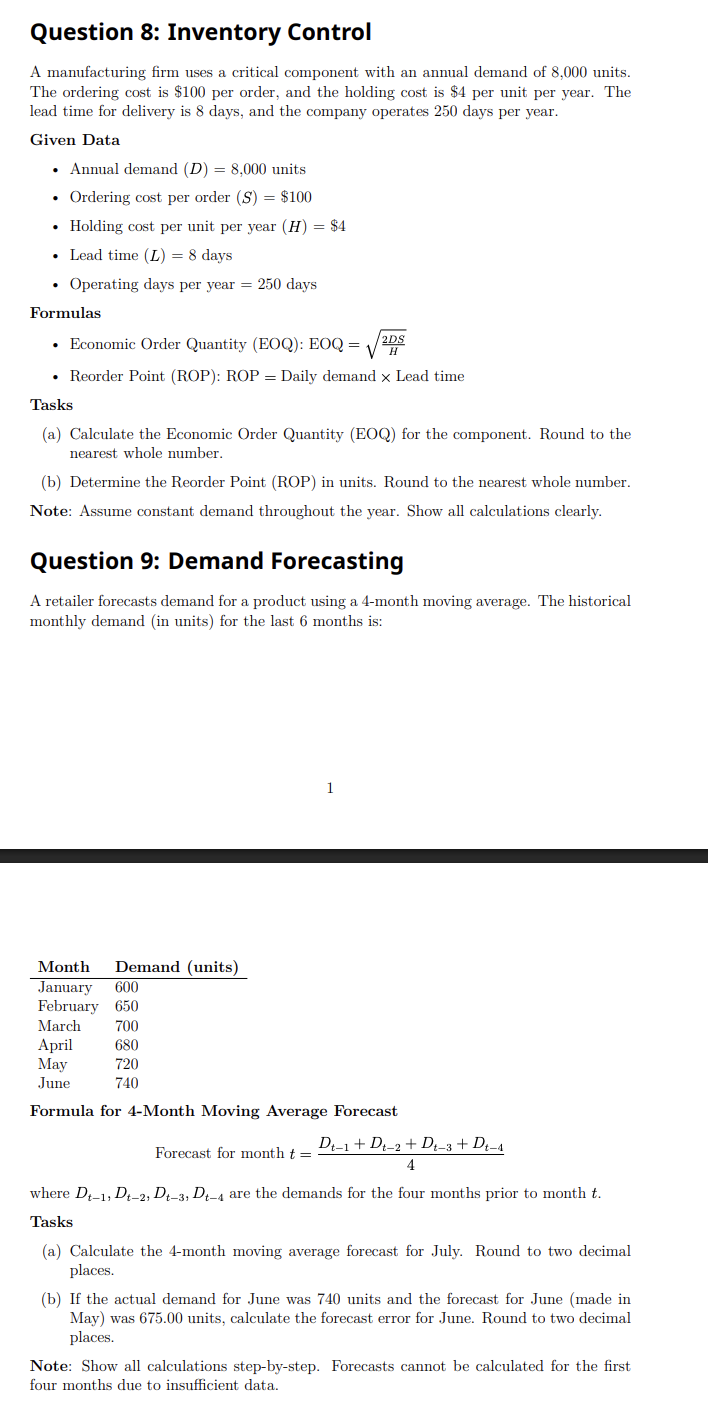

Question: Question 9 : Demand Forecasting A retailer forecasts demand for a product using a 4 - month moving average. The historical monthly demand ( i

Question : Demand Forecasting

A retailer forecasts demand for a product using month moving average. The historical

monthly demand units for the last months :

Formula for Month Moving Average Forecast

Forecast for month

where are the demands for the four months prior month

Tasks

Calculate the month moving average forecast for July. Round two decimal

places.

the actual demand for June was units and the forecast for June

May was units, calculate the forecast error for June. Round two decimal

places.

Note: Show all calculations stepstep. Forecasts cannot calculated for the first

four months due insufficient data. Question : Material Requirements Planning

A company produces a product requiring two components, A and with the following

details:

Additional Information

Planned production for week units

Current inventory: units, units

Tasks

Calculate the gross requirements for components A and for week

Determine the net requirements for components A and considering current

ventory, and the week which orders must placed meet week production.

Note: Show all calculations clearly. Assume safety stock. Question : Quality Control

A manufacturing process produces items with a defect rate A sample items

inspected daily.

Formulas

Expected number defects Sample size Defect rate

Standard deviation defects minutes Total available time per shift Orders per shift

Minimum number workers Total activity time Cycle time

Tasks

Calculate the cycle time required achieve the desired order rate. Round two

decimal places.

Determine the minimum number workers needed without exceeding the cycle

time.

Note: Show all calculations clearly.

Question : JustTime Inventory

A company implements a JIT system for a component with a daily demand units.

The setup cost per production run $ and the holding cost Question : JustTime Inventory

A company implements a JIT system for a component with a daily demand units.

The setup cost per production run $ and the holding cost $ per unit per day.

Given Data

Daily demand units

Setup cost per run $

Holding cost per unit per day $

Formula

Economic Production Quantity : EPQ

Tasks

Calculate the Economic Production Quantity for the component. Round

the nearest whole number.

Calculate the number production runs per year, assuming operating days.

Round the nearest whole numbe

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock