Question: Question: Do the SWOT (Strength, Weakness, Opportunity, and Threats) analysis of the company according to the case. ( must be 1000 words) Show graph if

Question: Do the SWOT (Strength, Weakness, Opportunity, and Threats) analysis of the company according to the case. ( must be 1000 words)

Show graph if necessary.

note: please don't waste my question if you can't fulfill my requirements.

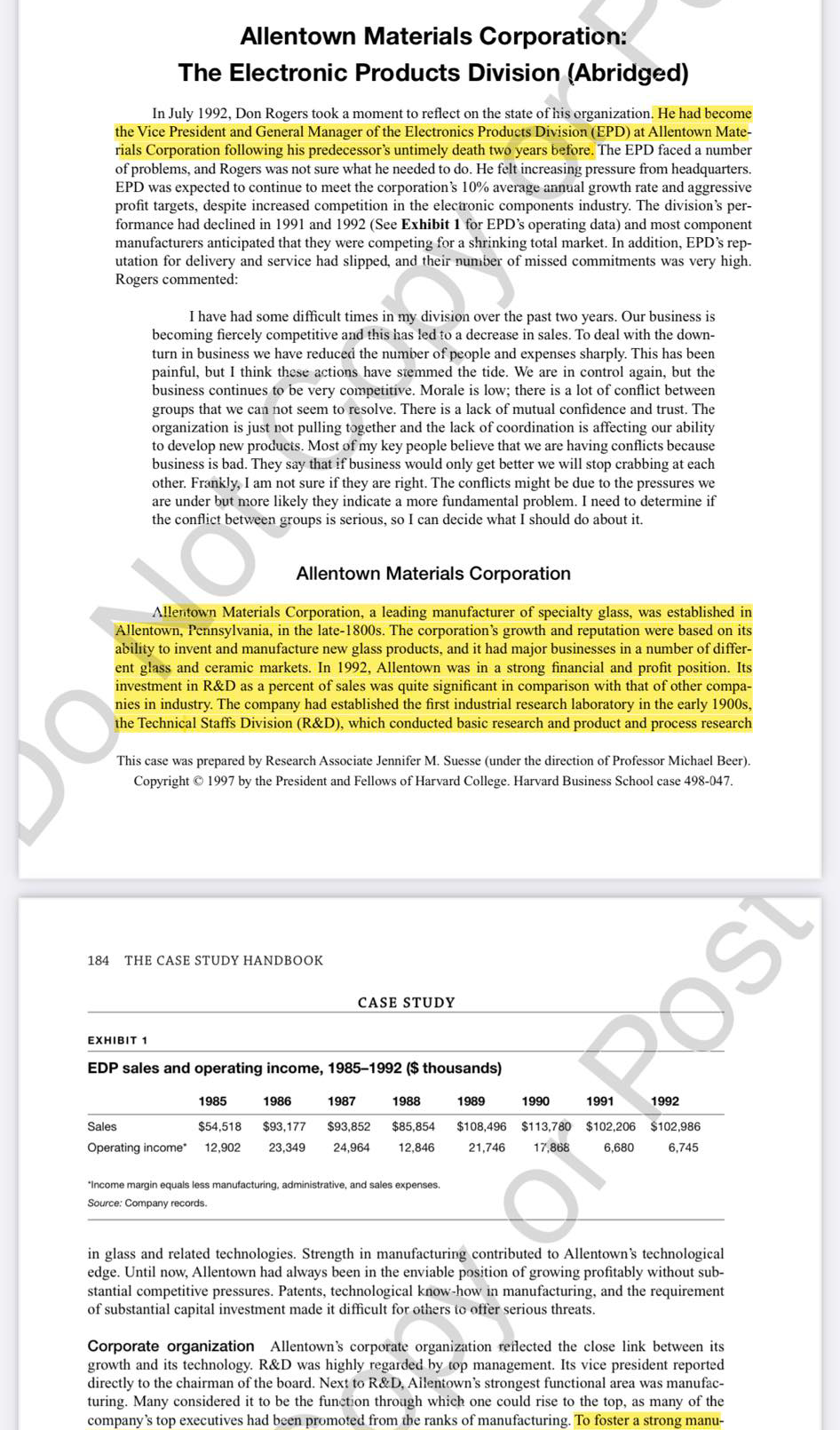

Allentown Materials Corporation: The Electronic Products Division (Abridged) In July 1992, Don Rogers took a moment to reflect on the state of his organization. He had become the Vice President and General Manager of the Electronics Products Division (EPD) at Allentown Mate- rials Corporation following his predecessor's untimely death two years before. The EPD faced a number of problems, and Rogers was not sure what he needed to do. He felt increasing pressure from headquarters. EPD was expected to continue to meet the corporation's 10% average annual growth rate and aggressive profit targets, despite increased competition in the electronic components industry. The division's per- formance had declined in 1991 and 1992 (See Exhibit 1 for EPD's operating data) and most component manufacturers anticipated that they were competing for a shrinking total market. In addition, EPD's rep- utation for delivery and service had slipped, and their number of missed commitments was very high. Rogers commented: I have had some difficult times in my division over the past two years. Our business is becoming fiercely competitive and this has led to a decrease in sales. To deal with the down- turn in business we have reduced the number of people and expenses sharply. This has been painful, but I think these actions have stemmed the tide. We are in control again, but the business continues to be very competitive. Morale is low; there is a lot of conflict between groups that we n not seem to resolve. There is a lack of mutual confidence and trust. The organization is just not pulling together and the lack of coordination is affecting our ability to develop new products. Most of my key people believe that we are having conflicts because business is bad. They say that if business would only get better we will stop crabbing at each other. Frankly, I am not sure if they are right. The conflicts might be due to the pressures we are under but more likely they indicate a more fundamental problem. I need to determine if the conflict between groups is serious, so I can decide what I should do about it. Allentown Materials Corporation Allentown Materials Corporation, a leading manufacturer of specialty glass, was established in Allentown, Pennsylvania, in the late-1800s. The corporation's growth and reputation were based on its ability to invent and manufacture new glass products, and it had major businesses in a number of differ- ent glass and ceramic markets. In 1992, Allentown was in a strong financial and profit position. Its investment in R&D as a percent of sales was quite significant in comparison with that of other compa- nies in industry. The company had established the first industrial research laboratory in the early 1900s, the Technical Staffs Division (R&D), which conducted basic research and product and process research This case was prepared by Research Associate Jennifer M. Suesse (under the direction of Professor Michael Beer). Copyright 1997 by the President and Fellows of Harvard College. Harvard Business School case 498-047. 184 THE CASE STUDY HANDBOOK CASE STUDY EXHIBIT 1 EDP sales and operating income, 19851992 ($ thousands) Posi OM 1985 1986 1987 1988 1989 1990 1991 1992 Sales $54,518 $93,177 $102,986 $93,852 24,964 $85,854 12,846 $108,496 $113,780 $102,206 21.746 17,868 Operating income 12,902 23,349 6,680 6,745 *Income margin equals less manufacturing, administrative, and sales expenses. Source: Company records. in glass and related technologies. Strength in manufacturing contributed to Allentown's technological edge. Until now, Allentown had always been in the enviable position of growing profitably without sub- stantial competitive pressures. Patents, technological know-how in manufacturing, and the requirement of substantial capital investment made it difficult for others to offer serious threats. Corporate organization Allentown's corporate organization reflected the close link between its growth and its technology. R&D was highly regarded by top management. Its vice president reported directly to the chairman of the board. Next to R&D, Ailentown's strongest functional area was manufac- turing. Many considered it to be the function through which one could rise to the top, as many of the company's top executives had been promoted from the ranks of manufacturing. To foster a strong manu- company's top executives had been promoted from the ranks of manufacturing. To foster a strong manu- facturing orientation, the company had developed a control system in which plants were viewed as profit centers. Financial results were reported every 28 days and were reviewed 13 times a year. These periodic reviews were conducted at all levels of the corporation. For many years all of Allentown's operations were based in its headquarters, but as the company grew, plants and sales offices were established throughout the world. In 1992, all but two of the corpora- tion's eight line divisions had their headquarters in Allentown. Thus, most divisions could discuss busi- ness problems on a face-to-face basis; the corporation operated like a relatively close-knit family. People saw each other frequently on Allentown's premises, on the streets of the town, and on social occasions. People at all levels and from diverse parts of the corporation interacted informally. It would not be uncommon for top-level corporate officers to meet divisional personnel in the main office building and to engage them in informal discussions about the state of their business-asking about orders, ship- ments, sales, and profits for the period. The EPD and Its History The Electronic Products Division (EPD) manufactured high-quality electronic components (resis- tors and capacitors) for several markets. More than half of the EPD's 1992 sales were to original equip- ment manufacturers (OEMs) who bought resistors and capacitors in large volume for use in a variety of CASE: ALLENTOWN MATERIALS CORPORATION ISO CASE STUDY their products. The remainder of the division's sales were to distributors who resold the components in smaller quantities. Much like other Allentown businesses, the components business grew due to the EPD's unique technological capabilities. Many of their competitively unique new products were invented in response to needs from OEMs who wanted the EPD to apply its research and development strength to meet their stringent component specifications. The Component Market Through the mid-1980s, the space program and the military's reliance on missile defense systems created demand for highly reliable components, since failure threatened the integrity of very sophisticated and expensive equipment. The government was willing to pay premium prices for components that met its very strict specifications, and Allentown's knowledge base enabled it to serve this market well. In the late 1980s, the nature of EPD's business began to shift. As the cold war began to ebb and the military market declined, the division concentrated more of its efforts in commercial markets. For exam- ple, the personal computer (PC) market was exploding. The growing market in telecommunications devices, such as cellular telephones, personal pagers (beepers), facsimile machines, and other consumer electronics products also provided new opportunities for the EPD components. Using its unique techno- logical capabilities in product development and manufacturing, the EPD was able to enter these new markets and quickly establish a major position in them. In response to the high-volume demands of these markets, the EPD built a plant in Evans, Georgia in 1990. By 1992, 60% of the EPD's sales were to the computer, telecommunications and consumer elec- tronics markets. The EPD's management felt continual pressure to extend existing product lines as OEMs developed new end-use products for their growing markets. Responding to customers' unique needs with new product extensions was a competitive necessity because new products commanded higher prices in their early stages of development and thereby offered an opportunity for growth. At the same time that these commercial markets were growing, buyers were becoming more price sensitive. This prompted increased and often fierce price competition among component suppliers. Competition hinged primarily on price but quality and service were also important. Customers were giving special consideration to manufacturers that could assure short delivery lead times (usually no more than four weeks), but efficiency in manufacturing operations demanded longer lead times. Stricter quality standards were also being demanded because poor quality often could shut down an OEM's production operation. As suppliers competed for large-volume contracts from major OEMs, prices fell sharply, putting pressure on costs. To Rogers and his managers, it appeared as if the EPD was becoming a commodity business. The EPD's future in this dynamic and uncertain environment looked bleak indeed. It was the sub- ject of much discussion and controversy in the division. Volume could always be increased by taking low-price business, but this reduced profitability. Most people within EPD looked to new products as a major source of both new volume and profits. Some managers wondered whether their division could meet Allentown's high expectations for profitability and growth, or even survive. Management History: Joe Bennett's legacy Before 1990, Joe Bennett headed the EPD. An entre preneur who sought to get his division into new businesses, Bennett had been in charge of the EPD since its infancy and nurtured it into a significant business for Allentown. Under Bennett's leadership, the EPD was one of the two Allentown divisions with headquarters outside Allentown, Pennsylvania. This was a source of some pride to Bennett. He fostered the desire to grow and a spirit of experimentation at the EPD. For example, Bennett seized one opportunity for growth by personally initiating research into a new technology that sought to bridge components and integrated circuits. Scott Allen, the division's con- troller until 1990, felt Bennett exemplified the division's strengths: We always tried new things. We always experimented. We set a fast pace. There was a feeling of urgency and commitment and dissatisfaction with the status quo. As an example, we were 14 steps ahead in computer applications. This stemmed from Bennett and the dynamic industry we were in. Bennett, who was 48 years old when he died, was a big man with a quick and creative mind. He ran the division almost single-handedly. For example, both the Barnett (capacitors) and the Hopewell (resistors) plants had separate on-site market development and product development groups. The man- agers of all these groups reported to Bennett. Many of the key decisions were made by him and none were made without his knowledge and approval. People respected and also feared Bennett. A product development manager for capacitors described Bennett and his style: Joe was very authoritarian with me and others. As a result, the most successful people working for Bennett were political and manipulative. People did not extend themselves very much to disagree with him. Bennett had a significant impact on our organization; our managerial styles came to reflect his. We were all more authoritarian than we might otherwise have been. I was less willing to let my people make mistakes even though I thought it was important that people learn from their mistakes. The pressure and unrealistic standards were transmitted down to people throughout the organization. This resulted in our commitments often being un- realistic. There was little group activity and decision making by the top team except where there was a specific problem. It was not a natural group. We were never together except at formal managers' meetings. There was no cohesiveness in the group reporting to Bennett. Bennett was a man of paradoxes. Although most people felt he was extremely directive in his man- agement styie, he was intensely interested in the field of organizational behavior and its applications to management. In 1989, Bennett initiated a division-wide management and organization development program. The program was to include several phases: an examination of individual management styles, group effectiveness, interfunctional coordination, and organization-wide problems. In all phases, action plans for improvement were to be developedStep by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock