Question: Question: Draw examples/strategies from the case to explain how Cheng Hsong strives to add value by improving its value chain? The Chen Hsong Machinery Co.

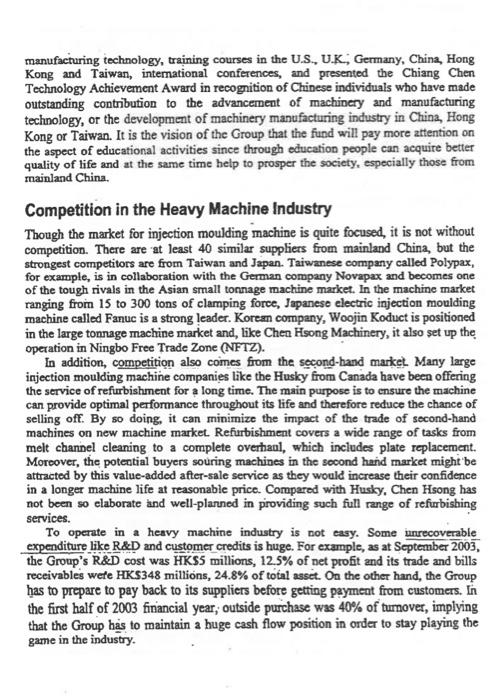

The Chen Hsong Machinery Co. LtD. Background Established in 1958 by Dr. Chiang Chen, "Chen Hsong Machinery Co. Ltd. is the world's leading injection moulding machine manufacturer with research teams and production lines located in Hong Kong. Taiwan and mainland China. It sells to markets all over the world through 40 overseas distributors and agents. In order to suit customers' specific 'application, their injection moulding machines are designed with clamping force ranging from 20 to 3,200 tons and shot capacity from 1 to 736oz. The company offers one stop total manufacturing solutions to customers with its fully integrated business operation, including research and development, parts production, machine assembly and pre-sales and after-sales services. To better serve the market of mainland China, which takes up more than 60% of its total tumover in 2003, the company has set up sales offices in Beijing, Dongguan, Zhongshan, Ningbo and Shenyang and is committed to providing round-the-clock pre-sales and after-sales services. In 1991, Chen Hsong Holdings Ltd. was publiely listed in the Hong Kong Stock Exchange and Chen Hsong Machinery becomes its principal subsidiary. The main factory is at Tai Po Industrial Estate, with 170,000 sq. ft and 1,000 dedicated staff. Group Mission and Social Responsibilities The company is committed to the manufacture of superior products, providing "Japanese Quality at PRC costs". By employing high-precision computerized production processes and modem management spproach, the company believes that top quality products at competitive prices could be achieved. "Striving for Excellence" is also the company's philosophy, which will drive the staff to constantly improve product quality and customer service, enhancing its competitive edge as a result. Management also continues to invest on R\&D and manufacturing technology to achieve technological excellence. As a payback to society, Dr. Chiang Chen, the chairman of the Group, contributes all his shares to set up a fund called the Chisng Chen Industrial Charity Foundation. The objectives of the foundation are to encourage and assist in: a) the research and development (R\&D) of new machine tools; b) the improvement of tochoology and production tochniques in the mechanical manufacturing; c) the training of industrial talents. Over the years, the fund has supported and sponsored research programs on * The case is written to illastrate management coocepts; not to suggest any efficetive/ineffoctive badiling of the situation. manufacturing technology, training courses in the U.S., U.K., Germany, China, Hong Kong and Taiwan, intemational conferences, and presented the Chiang Chen Technology Achievement Award in recognition of Chinese individuals who have made outstanding contribution to the advancement of machinery and manufacturing technology, or the development of machinery manufacturing industry in China, Hong Kong or Taiwan. It is the vision of the Group that the fund will pay more attention on the aspect of educational activities since through education people can acquire better quality of life and at the same time help to prosper the society, especially those from mainland China. Competition in the Heavy Machine Industry Though the market for injection moulding machine is quite focused, it is not without competition. There are at least 40 similar suppliers from mainland China, but the strongest competitors are from Taiwan and Japan. Taiwanese company called Polypax, for example, is in collaboration with the German company Novapax and becomes one of the tough rivals in the Asian small tonnage machine market. In the machine market ranging from 15 to 300 tons of clamping force, Japanese electric injection moulding machine called Fanuc is a strong leader. Korem company, Woojin Koduct is positioned in the large tonnage machine market and, like Chen Hsong Machinery, it also set up the operation in Ningbo Free Trade Zone (NFTZ). In addition, competition also comes from the second-hand market. Many large injection moulding machine companies like the Husky from Canada have been offering the service of refurbishment for a long time. The main purpose is to ensure the machine can provide optimal performance throughout its life and therefore reduce the chance of selling off. By so doing, it can minimize the impact of the trade of second-hand machines on new machine market. Refurbishment covers a wide range of tasks from melt channel cleaning to a complete overhanl, which includes plate replacement. Moreover, the potential buyers souring machines in the socond hand market might'be attracted by this value-added after-sale service as they would increase their confidence in a longer machine life at reasonable price. Compared with Husky, Chen Hsong has not been so elaborate and well-planned in providing such full range of refurbishing services. To operate in a heavy machine industry is not easy. Some unrecoverable expenditure like R\&D and customer credits is huge. For example, as at September 2003. the Group's R\&D cost was HKS5 millions, 12.5% of net profit and its trade and bills receivables wete HKS 348 millions, 24.8% of total asset. On the other hand, the Group has to prepare to pay back to its suppliers before getting paymeat from customers. In the first half of 2003 financial year, outside purchase was 40% of tumover, implying that the Group has to maintain a huge cash flow position in order to stay playing the game in the industry. Operations of the Group The market for plastic injection machines in 2003 was generally strong. The Group achieved 6% growth in sales tumover while the biggest jump was in overseas countries. The following table shows tbe breakdown of turnover based on location of customers. Sales Turnover for the Str Moutha Eaded 30 September (ia milliou HKS) Obviously, mainland China is the lergest market for the Group's products as it makes up more than 50% and 60% of the total sales in 2002 and 2003 respectively. Both Hong Kong and Taiwan were seriously affected by the outbreak of Severe Acute Respiratory Syndrome (SARS) and therefore recorded a drop in deraand for industrial machines. Sales in the coming year would be rebound according to the recent economic recovery in Hong Kong, Taiwan and mainland China However, cost reduction is becoming the company's long term effort. It includes the following initiatives. First, an assembly centre was set up in Ningbo Free Trade Zone (NFIZ), which is chosen by the Chinese government 'as the strategic key area for development. According to the preferential policies, the Group was granted the exemption of imported VAT, regulation tax, license foe and also the permission of opening foreign exchange account, leading to a huge cost saving. Secondly, the Group established Chen Hsong Industrial Park at Shenzhen in 2000 as a means to lowering production cost as well as expanding production capacity. Compared with the plant in Hong Kong (about 170,000 square meters), the Industrial Park in Shecthen is nearly 3.5 times larger, ic. 600,000 square meters, enabling the production output to inerease from 3,300 machines per year to 10,000 machines per year. In fact, the import tax in Shenchen stands as high as that in Hong Kong but manufacturing in Shenzhen is much cheaper, taking into account the land cost, local materials cost, logistic cost and, most important of all, the staff cost. Thirdly, the introduction of Oracle ERP (Enterprise Resource Pianning) System in 2001 had belped the Group to perform day-to-day operations in a more efficient and accurate way. It is therefore more cost-effective in resource utilization. In addition to cost control, the company also pays particular attention to quality issue. For example, in order to ensure good quality of products, the company installs a series of quality control mechanism, from R\&D to incoming quality control (IQC), inprocess quality control (IPQC), final quality control (FQC) and outgoing quality control (OQC). Each machine must also undergo throe day-and-night, i.e. 72 hours, of reliability testing so as to increase its durability. The chaiman of the Group believes that staff education and promotion of a cooperative culture is of paramount importance to product quality. He therefore implements the SS straiegy (in Japanese: Seiri, Seiton, Seiso, Seiketsu and Shitsuke) in the company as a means to training people, especially the lower level. staff, to follow the rules of work and to establish a "human sense" maagement. A good after sales customer service is critical in the market of heavy machinery as bad quality and machine accident may lead to litigation case, thus damaging the company's reputation. The Group therefore provides a 24-hour inspection service and set up a 3-year warranty policy for its products. Recent Development After forming the joint venture with Guangoiong Macrc Company Limited in Shunde for more than 12 years, the Group intitiated to acquire 49% share interests from the other partner in 2003 . The purpose of such a strategic move is to consolidate the customers in China so as to accelerate market development. As a result, the profit contribution to the Group by this subsidiary is increased from 25% to 40%. In the past, the Group relied on the supply of parts and mattrials frrm import: For sxample, more than half of the company's computer control systems viere imported from Japan. To retain better control on the supply and cost of zomponent parts, a subsidiary company called Machinery Equipment Compary Ltd. was set up in early 2003 to make tie bar for moulding machine. Moreover, many similar manufacturing companies were also established to make component parts, e.g. hydraulic motors, semi-automatic computer control system, ete. to supply to the Group for machine assembly. Apart from enhancing value in upstream integration, the company also intended to improve its overseas distribution network by setting up sales offices in Brazil, Dubai, Mexico and Canada. At present, the Group sells machines in Britain, Spain and Greek through sales agents. The costs of sales offices are relatively lower than sales agents as the latter usually charges higher commission and licensing fee. However, before establishing a large scalc sales network by appointing agents, setting up company-owned sales offices would be a very useful means in testing market

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts