Question: QUESTION ONE (30 MARKS) Read the case study below and answer all questions that follow. Love it or hate it, IKEA is the most successful

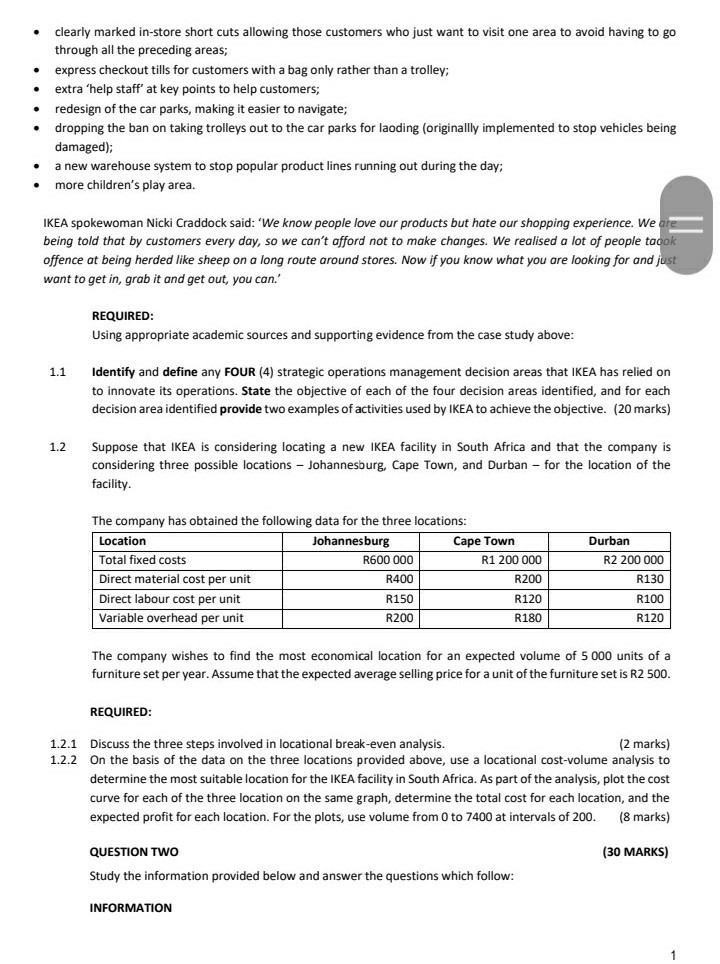

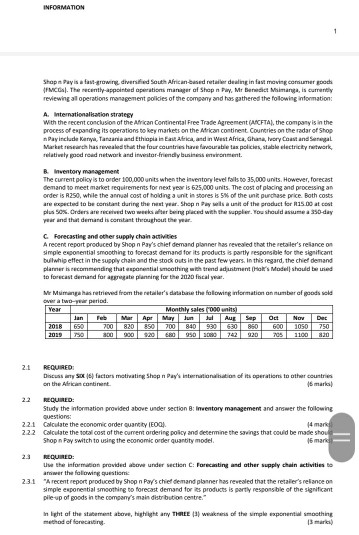

QUESTION ONE (30 MARKS) Read the case study below and answer all questions that follow. Love it or hate it, IKEA is the most successful furniture retailer ever. With 276 stores in 36 countries, they have managed to develop their own special way of selling furniture. Their stores' layout means customers often spend two hours in a store - far longer than in rival furniture retailers. IKEA's philosophy goes back to the original business, started in the 1950s in Sweden by Ingwar Kamprad. He built a showroom on the outskirts of Stockholm where land was cheap and simply displayed suppliers' furniture as it would be in a domestic setting. Increasing sales soon allowed IKEA to start ordering its own self-designed products from local manufacturers. But it was innovation in its operations that dramatically reduced its selling costs. These included the idea of selling furniture as self-assembly flat packs, which reduced production and transport costs, and its 'showroom-warehouse' concept, which required customers to pick the furniture up themselves from the warehouse (which reduced retailing costs). Both of these operating principles are still the basis of IKEA's retail operations process today. Stores are designed to facilitate the smooth flow of customers, from parking, moving through the store itself, to ordering and picking up goods. At the entrance to each store large notice boards provide advice to shoppers. For young children, there is a supervised play area for a time. Parents are recalled via the loudspeaker system if the child has any problems. IKEA allow customers to make up their minds in their own time' but 'information point' have staff who can help. All furniture carries a ticket with code number which indicates its location in the warehouse. (For larger items customers go to the information desks for assistance.) There is also an area where smaller items are displayed, and can be picked directly. Customers then pay at the checkouts, where a ramped conveyor belt moves purchases to the checkout staff. The exit area has service points, and a loading area that allows customers to bring their cars from the car park and load their purchases. Behind the public face of IKEA's huge stores is a complex worldwide network of suppliers. 1 300 direct suppliers, about 10 000 sub-suppliers, and wholesale and transport operations, including 26 distribution centres. This supply network is vitally important to IKEA. From purchasing raw materials, right through to finished products arriving in its customers' homes, IKEA relies on close partnership with its suppliers to achieve both ongoing supply efficiency and new product development. However, IKEA closely controls all supply and development activities from IKEA's hometown of lmhult in Sweden. But success brings its own problems and some customers became increasingly frustrated with overcrowding and long waiting times. In response IKEA launched a programme 'designing out the bottlenecks. The changes included: clearly marked in-store short cuts allowing those customers who just want to visit one area to avoid having to go through all the preceding areas; express checkout tills for customers with a bag only rather than a trolley; extra 'help staff at key points to help customers; redesign of the car parks, making it easier to navigate; dropping the ban on taking trolleys out to the car parks for laoding (originallly implemented to stop vehicles being damaged); a new warehouse system to stop popular product lines running out during the day more children's play area. . IKEA spokewoman Nicki Craddock said: 'We know people love our products but hate our shopping experience. We being told that by customers every day, so we can't afford not to make changes. We realised a lot of people tacok offence at being herded like sheep on a long route around stores. Now if you know what you are looking for and just want to get in, grab it and get out, you can.' REQUIRED: Using appropriate academic sources and supporting evidence from the case study above: 1.1 Identify and define any FOUR (4) strategic operations management decision areas that IKEA has relied on to innovate its operations. State the objective of each of the four decision areas identified, and for each decision area identified provide two examples of activities used by IKEA to achieve the objective. (20 marks) 1.2 Suppose that IKEA is considering locating a new IKEA facility in South Africa and that the company is considering three possible locations - Johannesburg, Cape Town, and Durban - for the location of the facility. The company has obtained the following data for the three locations: Location Johannesburg Cape Town Total fixed costs R600 000 R1 200 000 Direct material cost per unit R400 R200 Direct labour cost per unit R150 R120 Variable overhead per unit R200 R180 Durban R2 200 000 R130 R100 R120 The company wishes to find the most economical location for an expected volume of 5 000 units of a furniture set per year. Assume that the expected average selling price for a unit of the furniture set is R2 500. REQUIRED: 1.2.1 Discuss the three steps involved in locational break-even analysis. (2 marks) 1.2.2 On the basis of the data on the three locations provided above, use a locational cost-volume analysis to determine the most suitable location for the IKEA facility in South Africa. As part of the analysis, plot the cost curve for each of the three location on the same graph, determine the total cost for each location, and the expected profit for each location. For the plots, use volume from 0 to 7400 at intervals of 200. (8 marks) QUESTION TWO (30 MARKS) Study the information provided below and answer the questions which follow: INFORMATION INFORMATION Shop Pays-prin diversified South African-based real dealing in fast moving consumer good PMCO). The recently-appointed operation manager of Shop n Pay, Mr Benedict Mmanga, is currently reviewing all operations Management policies of the company and has gathered the following information: A. Internationalisation strategy With the recent conclusion of the African Continental Free Trade Agreement (ARCFTA), the company is in the process of expanding its operations to key markets on the African continent countries on the radar of Shop Payinclude Kanya, Tansania and Ethiopia in East Africa, and in West Africa, Ghane, tory Coast and Smal Market research has revealed that the four countries are fincurabile tas policies, stablectricky utwork relatively good road network and inventor-friendly business content B Inventory management The current policy is to order 100.000 units when the inventory level falls to 35,000 units. However, forecast demand to meet market requirements for next year is 625,000 units. The cost of placing and processing an order is R250, while the annual cost of holding a unit in stores is 5% of the unit purchase price. Both costs are repected to be comitant during the next year. Shop n Pay is a unit of the product for Rs.00 at cost plus sex. Orders are received two weeks after berre placed with the supplier Toushould seaso-day year and that demand is comitant throughout the year. Forecasting and other supply chain activities A recent report produced by Shop n Pay's chief demand planner has revealed that the retailer's relance on simple exponential smoothing to forecast demand for its products is partly responsible for the significant bullwhip effect in the supply chain and the stock outs in the past few years. In this regard, the chief demand planer Iris recommend that partial nothing with trend adjustment (Hos Model should be used to forecast demand for at planning for the 2020 fsical Mr Mumangahas retrieved from the retailer's database the following information on number of foods sold Over two-year period Year Monthly sales ('000 units lan Mar Apr May Jul Aug Sep Oct Nov Dec 650 700 820 859 700 840 930 630 850 600 750 2019 800 900 920 680 950309 920 705 2100 2018 3050 = 2.1 REQUIRED: Discussy SOK 16 factors motivating Shop n Pay's nationalition of its operations to other countries on the African content 22 REQUIRED: Study the information provided above under section B: Inventory management and answer the following questions: 22.1 Calculate the economic order quantity EOQ). 14 mart 222 Calculate the total cost of the current ordering policy and determine the swings that could be made should Shop n Pay switch to using the economic order quantity model. 16 man REQUIRED: Uw the information provided above under section C: Forecasting and other supply chain activities to awer the following question 23.1 "A recent report produced by Shop n Pay's chief demand planner has revealed that the retailers reliance on simple exponential smoothing to forecast demand for its products is partly responsible of the significant pile-up of goods in the company's main distribution centre." In light of the statement abort, highlight any THREE 1 wees of the simple exponential smoothing method of forecast 2.3.2 Calculate the Exponential smoothing with trend component forecast (FIT) for second to the twenty-fifth month using an initial trend forecast (T) of 10 000, an initial exponential smoothing forecast (F) of 640 000 units, a = 0.20, and B = 0.30. (6 marks) 2.3.3 Plot the actual demand, the simple exponential smoothing (SES) forecast, and trend-adjusted exponential smoothing (FIT) forecast on the same graph. Briefly comment on the observed difference(s) between the plots of the two forecasts. (5 marks) QUESTION ONE (30 MARKS) Read the case study below and answer all questions that follow. Love it or hate it, IKEA is the most successful furniture retailer ever. With 276 stores in 36 countries, they have managed to develop their own special way of selling furniture. Their stores' layout means customers often spend two hours in a store - far longer than in rival furniture retailers. IKEA's philosophy goes back to the original business, started in the 1950s in Sweden by Ingwar Kamprad. He built a showroom on the outskirts of Stockholm where land was cheap and simply displayed suppliers' furniture as it would be in a domestic setting. Increasing sales soon allowed IKEA to start ordering its own self-designed products from local manufacturers. But it was innovation in its operations that dramatically reduced its selling costs. These included the idea of selling furniture as self-assembly flat packs, which reduced production and transport costs, and its 'showroom-warehouse' concept, which required customers to pick the furniture up themselves from the warehouse (which reduced retailing costs). Both of these operating principles are still the basis of IKEA's retail operations process today. Stores are designed to facilitate the smooth flow of customers, from parking, moving through the store itself, to ordering and picking up goods. At the entrance to each store large notice boards provide advice to shoppers. For young children, there is a supervised play area for a time. Parents are recalled via the loudspeaker system if the child has any problems. IKEA allow customers to make up their minds in their own time' but 'information point' have staff who can help. All furniture carries a ticket with code number which indicates its location in the warehouse. (For larger items customers go to the information desks for assistance.) There is also an area where smaller items are displayed, and can be picked directly. Customers then pay at the checkouts, where a ramped conveyor belt moves purchases to the checkout staff. The exit area has service points, and a loading area that allows customers to bring their cars from the car park and load their purchases. Behind the public face of IKEA's huge stores is a complex worldwide network of suppliers. 1 300 direct suppliers, about 10 000 sub-suppliers, and wholesale and transport operations, including 26 distribution centres. This supply network is vitally important to IKEA. From purchasing raw materials, right through to finished products arriving in its customers' homes, IKEA relies on close partnership with its suppliers to achieve both ongoing supply efficiency and new product development. However, IKEA closely controls all supply and development activities from IKEA's hometown of lmhult in Sweden. But success brings its own problems and some customers became increasingly frustrated with overcrowding and long waiting times. In response IKEA launched a programme 'designing out the bottlenecks. The changes included: clearly marked in-store short cuts allowing those customers who just want to visit one area to avoid having to go through all the preceding areas; express checkout tills for customers with a bag only rather than a trolley; extra 'help staff at key points to help customers; redesign of the car parks, making it easier to navigate; dropping the ban on taking trolleys out to the car parks for laoding (originallly implemented to stop vehicles being damaged); a new warehouse system to stop popular product lines running out during the day more children's play area. . IKEA spokewoman Nicki Craddock said: 'We know people love our products but hate our shopping experience. We being told that by customers every day, so we can't afford not to make changes. We realised a lot of people tacok offence at being herded like sheep on a long route around stores. Now if you know what you are looking for and just want to get in, grab it and get out, you can.' REQUIRED: Using appropriate academic sources and supporting evidence from the case study above: 1.1 Identify and define any FOUR (4) strategic operations management decision areas that IKEA has relied on to innovate its operations. State the objective of each of the four decision areas identified, and for each decision area identified provide two examples of activities used by IKEA to achieve the objective. (20 marks) 1.2 Suppose that IKEA is considering locating a new IKEA facility in South Africa and that the company is considering three possible locations - Johannesburg, Cape Town, and Durban - for the location of the facility. The company has obtained the following data for the three locations: Location Johannesburg Cape Town Total fixed costs R600 000 R1 200 000 Direct material cost per unit R400 R200 Direct labour cost per unit R150 R120 Variable overhead per unit R200 R180 Durban R2 200 000 R130 R100 R120 The company wishes to find the most economical location for an expected volume of 5 000 units of a furniture set per year. Assume that the expected average selling price for a unit of the furniture set is R2 500. REQUIRED: 1.2.1 Discuss the three steps involved in locational break-even analysis. (2 marks) 1.2.2 On the basis of the data on the three locations provided above, use a locational cost-volume analysis to determine the most suitable location for the IKEA facility in South Africa. As part of the analysis, plot the cost curve for each of the three location on the same graph, determine the total cost for each location, and the expected profit for each location. For the plots, use volume from 0 to 7400 at intervals of 200. (8 marks) QUESTION TWO (30 MARKS) Study the information provided below and answer the questions which follow: INFORMATION INFORMATION Shop Pays-prin diversified South African-based real dealing in fast moving consumer good PMCO). The recently-appointed operation manager of Shop n Pay, Mr Benedict Mmanga, is currently reviewing all operations Management policies of the company and has gathered the following information: A. Internationalisation strategy With the recent conclusion of the African Continental Free Trade Agreement (ARCFTA), the company is in the process of expanding its operations to key markets on the African continent countries on the radar of Shop Payinclude Kanya, Tansania and Ethiopia in East Africa, and in West Africa, Ghane, tory Coast and Smal Market research has revealed that the four countries are fincurabile tas policies, stablectricky utwork relatively good road network and inventor-friendly business content B Inventory management The current policy is to order 100.000 units when the inventory level falls to 35,000 units. However, forecast demand to meet market requirements for next year is 625,000 units. The cost of placing and processing an order is R250, while the annual cost of holding a unit in stores is 5% of the unit purchase price. Both costs are repected to be comitant during the next year. Shop n Pay is a unit of the product for Rs.00 at cost plus sex. Orders are received two weeks after berre placed with the supplier Toushould seaso-day year and that demand is comitant throughout the year. Forecasting and other supply chain activities A recent report produced by Shop n Pay's chief demand planner has revealed that the retailer's relance on simple exponential smoothing to forecast demand for its products is partly responsible for the significant bullwhip effect in the supply chain and the stock outs in the past few years. In this regard, the chief demand planer Iris recommend that partial nothing with trend adjustment (Hos Model should be used to forecast demand for at planning for the 2020 fsical Mr Mumangahas retrieved from the retailer's database the following information on number of foods sold Over two-year period Year Monthly sales ('000 units lan Mar Apr May Jul Aug Sep Oct Nov Dec 650 700 820 859 700 840 930 630 850 600 750 2019 800 900 920 680 950309 920 705 2100 2018 3050 = 2.1 REQUIRED: Discussy SOK 16 factors motivating Shop n Pay's nationalition of its operations to other countries on the African content 22 REQUIRED: Study the information provided above under section B: Inventory management and answer the following questions: 22.1 Calculate the economic order quantity EOQ). 14 mart 222 Calculate the total cost of the current ordering policy and determine the swings that could be made should Shop n Pay switch to using the economic order quantity model. 16 man REQUIRED: Uw the information provided above under section C: Forecasting and other supply chain activities to awer the following question 23.1 "A recent report produced by Shop n Pay's chief demand planner has revealed that the retailers reliance on simple exponential smoothing to forecast demand for its products is partly responsible of the significant pile-up of goods in the company's main distribution centre." In light of the statement abort, highlight any THREE 1 wees of the simple exponential smoothing method of forecast 2.3.2 Calculate the Exponential smoothing with trend component forecast (FIT) for second to the twenty-fifth month using an initial trend forecast (T) of 10 000, an initial exponential smoothing forecast (F) of 640 000 units, a = 0.20, and B = 0.30. (6 marks) 2.3.3 Plot the actual demand, the simple exponential smoothing (SES) forecast, and trend-adjusted exponential smoothing (FIT) forecast on the same graph. Briefly comment on the observed difference(s) between the plots of the two forecasts

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock