Question: QUESTION ONE a) What are the inputs required for Material Requirements Planning (MRP)? (3 MARKS) b) What are the reasons for using a lot sizing

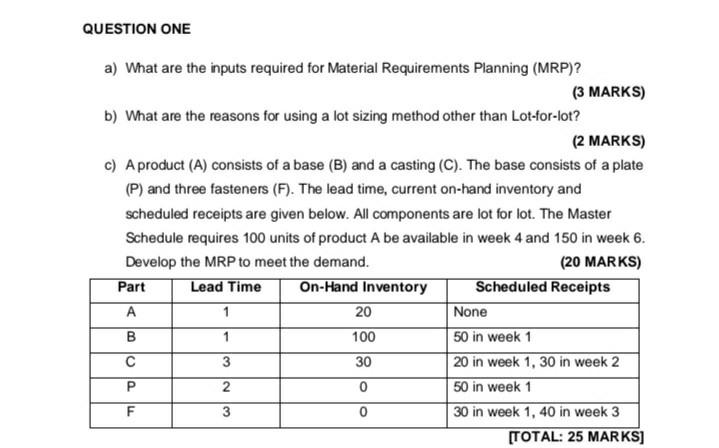

QUESTION ONE a) What are the inputs required for Material Requirements Planning (MRP)? (3 MARKS) b) What are the reasons for using a lot sizing method other than Lot-for-lot? (2 MARKS) c) A product (A) consists of a base (B) and a casting (C). The base consists of a plate (P) and three fasteners (F). The lead time, current on-hand inventory and scheduled receipts are given below. All components are lot for lot. The Master Schedule requires 100 units of product A be available in week 4 and 150 in week 6. Develop the MRP to meet the demand. (20 MARKS) Part Lead Time On-Hand Inventory Scheduled Receipts A 20 None B 100 50 in week 1 3 20 in week 1, 30 in week 2 P 2 0 50 in week 1 F 3 0 30 in week 1, 40 in week 3 [TOTAL: 25 MARKS] 1 1 30 N

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock