Question: question: pls fill in the table below Supply Chain Lean Six Sigma Case Study At least one project is occurring at each warehouse, this case

question: pls fill in the table below

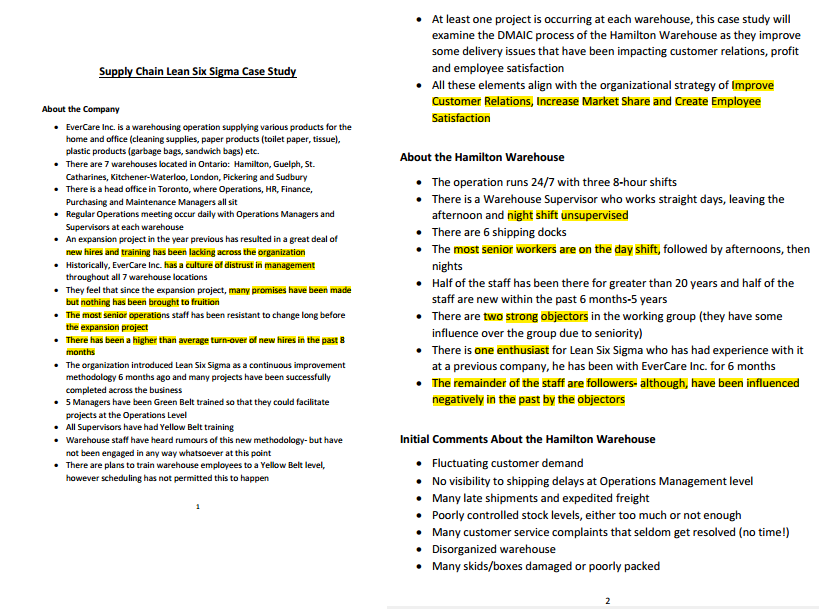

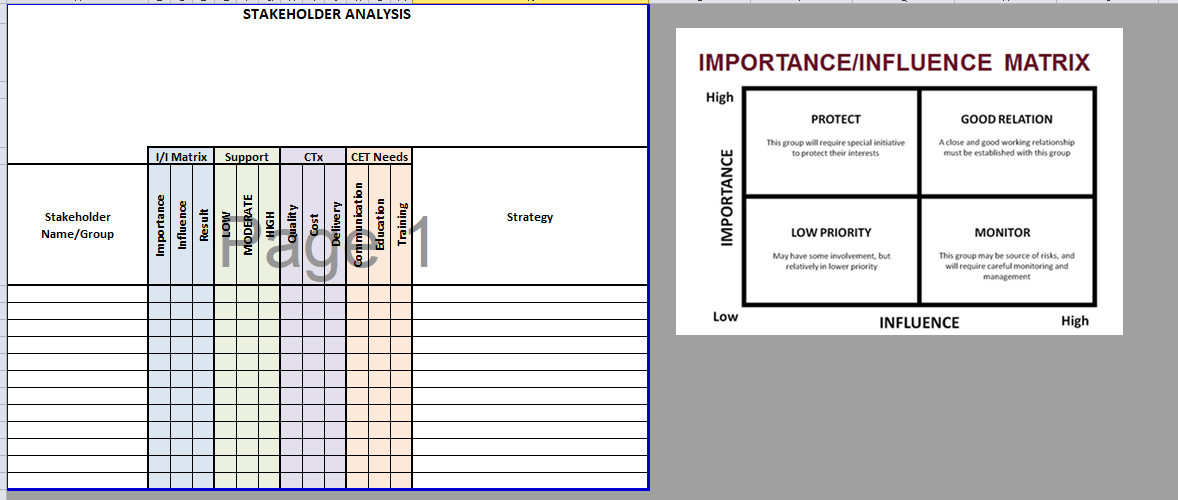

Supply Chain Lean Six Sigma Case Study At least one project is occurring at each warehouse, this case study will examine the DMAIC process of the Hamilton Warehouse as they improve some delivery issues that have been impacting customer relations, profit and employee satisfaction All these elements align with the organizational strategy of Improve Customer Relations, Increase Market Share and create Employee Satisfaction About the Company About the Hamilton Warehouse EverCare Inc. is a warehousing operation supplying various products for the home and office (cleaning supplies, paper products (toilet paper, tissue), plastic products (garbage bags, sandwich bags) etc. There are 7 warehouses located in Ontario: Hamilton, Guelph, St. Catharines, Kitchener-Waterloo, London, Pickering and Sudbury There is a head office in Toronto, where Operations, HR, Finance, Purchasing and Maintenance Managers all sit Regular Operations meeting occur daily with Operations Managers and Supervisors at each warehouse An expansion project in the year previous has resulted in a great deal of new hires and training has been lacking across the organization Historically, EverCare Inc. has a culture of distrust in management throughout all 7 warehouse locations They feel that since the expansion project, many promises have been made but nothing has been brought to fruition The most senior operations staff has been resistant to change long before the expansion project There has been a higher than average turn-over of new hires in the past 8 months The organization introduced Lean Six Sigma as a continuous improvement methodology 6 months ago and many projects have been successfully completed across the business 5 Managers have been Green Belt trained so that they could facilitate projects at the Operations Level All Supervisors have had Yellow Belt training Warehouse staff have heard rumours of this new methodology- but have not been engaged in any way whatsoever at this point There are plans to train warehouse employees to a Yellow Belt level, however scheduling has not permitted this to happen The operation runs 24/7 with three 8-hour shifts There is a Warehouse Supervisor who works straight days, leaving the afternoon and night shift unsupervised There are 6 shipping docks The most senior workers are on the day shift, followed by afternoons, then nights Half of the staff has been there for greater than 20 years and half of the staff are new within the past 6 months-5 years There are two strong objectors in the working group (they have some influence over the group due to seniority) There is one enthusiast for Lean Six Sigma who has had experience with it at a previous company, he has been with EverCare Inc. for 6 months The remainder of the staff are followers- although, have been influenced negatively in the past by the objectors Initial Comments About the Hamilton Warehouse Fluctuating customer demand No visibility to shipping delays at Operations Management level Many late shipments and expedited freight Poorly controlled stock levels, either too much or not enough Many customer service complaints that seldom get resolved (no time!) Disorganized warehouse Many skids/boxes damaged or poorly packed STAKEHOLDER ANALYSIS IMPORTANCE/INFLUENCE MATRIX High PROTECT GOOD RELATION This group will require special initiative to protect their interests A close and good working relationship must be established with this group 1/1 Matrix Support CTX CET Needs IMPORTANCE Stakeholder Strategy Name/Group LOW PRIORITY MONITOR May have some involvement, but relatively in lower priority This group may be source of risks, and will require careful monitoring and management Low INFLUENCE High Supply Chain Lean Six Sigma Case Study At least one project is occurring at each warehouse, this case study will examine the DMAIC process of the Hamilton Warehouse as they improve some delivery issues that have been impacting customer relations, profit and employee satisfaction All these elements align with the organizational strategy of Improve Customer Relations, Increase Market Share and create Employee Satisfaction About the Company About the Hamilton Warehouse EverCare Inc. is a warehousing operation supplying various products for the home and office (cleaning supplies, paper products (toilet paper, tissue), plastic products (garbage bags, sandwich bags) etc. There are 7 warehouses located in Ontario: Hamilton, Guelph, St. Catharines, Kitchener-Waterloo, London, Pickering and Sudbury There is a head office in Toronto, where Operations, HR, Finance, Purchasing and Maintenance Managers all sit Regular Operations meeting occur daily with Operations Managers and Supervisors at each warehouse An expansion project in the year previous has resulted in a great deal of new hires and training has been lacking across the organization Historically, EverCare Inc. has a culture of distrust in management throughout all 7 warehouse locations They feel that since the expansion project, many promises have been made but nothing has been brought to fruition The most senior operations staff has been resistant to change long before the expansion project There has been a higher than average turn-over of new hires in the past 8 months The organization introduced Lean Six Sigma as a continuous improvement methodology 6 months ago and many projects have been successfully completed across the business 5 Managers have been Green Belt trained so that they could facilitate projects at the Operations Level All Supervisors have had Yellow Belt training Warehouse staff have heard rumours of this new methodology- but have not been engaged in any way whatsoever at this point There are plans to train warehouse employees to a Yellow Belt level, however scheduling has not permitted this to happen The operation runs 24/7 with three 8-hour shifts There is a Warehouse Supervisor who works straight days, leaving the afternoon and night shift unsupervised There are 6 shipping docks The most senior workers are on the day shift, followed by afternoons, then nights Half of the staff has been there for greater than 20 years and half of the staff are new within the past 6 months-5 years There are two strong objectors in the working group (they have some influence over the group due to seniority) There is one enthusiast for Lean Six Sigma who has had experience with it at a previous company, he has been with EverCare Inc. for 6 months The remainder of the staff are followers- although, have been influenced negatively in the past by the objectors Initial Comments About the Hamilton Warehouse Fluctuating customer demand No visibility to shipping delays at Operations Management level Many late shipments and expedited freight Poorly controlled stock levels, either too much or not enough Many customer service complaints that seldom get resolved (no time!) Disorganized warehouse Many skids/boxes damaged or poorly packed STAKEHOLDER ANALYSIS IMPORTANCE/INFLUENCE MATRIX High PROTECT GOOD RELATION This group will require special initiative to protect their interests A close and good working relationship must be established with this group 1/1 Matrix Support CTX CET Needs IMPORTANCE Stakeholder Strategy Name/Group LOW PRIORITY MONITOR May have some involvement, but relatively in lower priority This group may be source of risks, and will require careful monitoring and management Low INFLUENCE High

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts