Question: Question(Activity Based Costing) Required: (a) Calculate the product cost per unit for each of Kirl and Strayt using Traditional Absorption Costing, recovering overheads using direct

Question(Activity Based Costing)

Required:

(a) Calculate the product cost per unit for each of Kirl and Strayt using Traditional Absorption Costing, recovering overheads using direct labour hours. Round costs per unit to the nearest penny. (6 marks)

(b) Calculate a product cost per unit for each of Kirl and Strayt using Activity Based Costing. Round costs per unit to the nearest penny. (16 marks)

(c) The selling price for the products Kirl and Strayt are 28 and 33 respectively. Discuss why there are differences in cost per unit and explain the impact on the resultant profit per unit. (10 marks)

(d) The company anticipates that competition will remain high in the industry and is, therefore, considering the implementation of Target Pricing to replace their Cost-plus system currently in use. Explain how this change could affect the returns to shareholders. (8 marks)

KINDLY SHOW ALL CALCULATIONS OR TABLES IN ELECTRONIC FORM

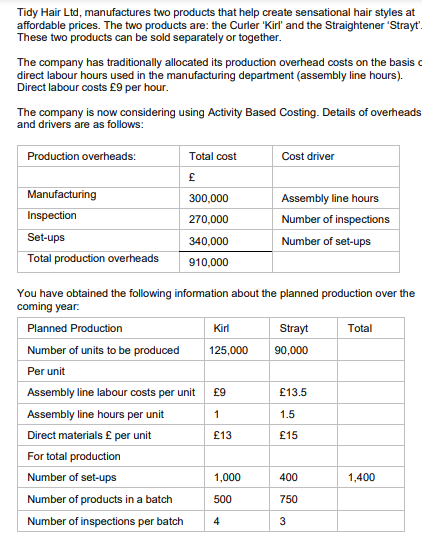

Tidy Hair Ltd, manufactures two products that help create sensational hair styles at affordable prices. The two products are: the Curler Kirl' and the Straightener 'Strayt' These two products can be sold separately or together. The company has traditionally allocated its production overhead costs on the basis direct labour hours used in the manufacturing department (assembly line hours). Direct labour costs 9 per hour. The company is now considering using Activity Based Costing. Details of overheads and drivers are as follows: Production overheads: Cost driver Manufacturing Inspection Set-ups Total production overheads Total cost 300,000 270,000 340,000 910,000 Assembly line hours Number of inspections Number of set-ups Total 9 You have obtained the following information about the planned production over the coming year. Planned Production Kirl Strayt Number of units to be produced 125,000 90,000 Per unit Assembly line labour costs per unit 13.5 Assembly line hours per unit 1.5 Direct materials per unit 15 For total production Number of set-ups 1,000 1,400 Number of products in a batch Number of inspections per batch 1 13 400 500 750 4 3 3

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts