Question: Questions Using the data in the appendices, calculate the full product cost of each product using the activity-based costing method. What do you think of

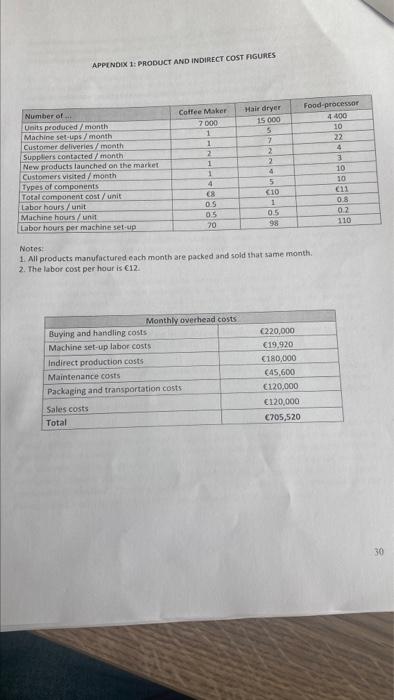

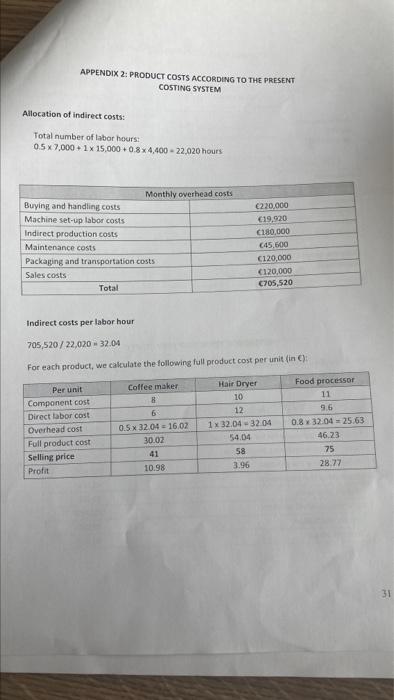

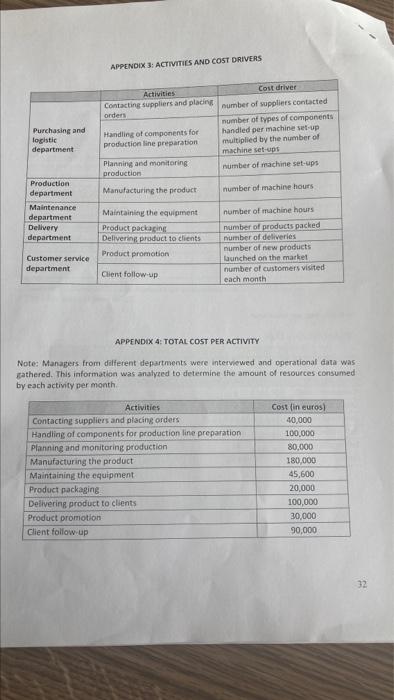

APPENDIX 1: PRODUCT AND INDIRECT COST FIGURES Number of... Coffee Maker Hair dryer 7 000 15 000 Units produced/month Machine set-ups/month Customer deliveries/month 5 1 1 7 Suppliers contacted / month 2 2 New products launched on the market. 1 2 Customers visited/month 1 4 Types of components 4 5 Total component cost / unit Labor hours/unit (8 10 0.5 1 Machine hours/unit 0.5 0.5 Labor hours per machine set-up 70 98 Notes: 1. All products manufactured each month are packed and sold that same month. 2. The labor cost per hour is 12. Monthly overhead costs Buying and handling costs 220,000 Machine set-up labor costs 19,920 Indirect production costs 180,000 Maintenance costs 45,600 Packaging and transportation costs 120,000 Sales costs 120,000 Total 705,520 Food-processor 4 400 10 22 4 3 10 10 (11 0.8 0.2 110 30 APPENDIX 2: PRODUCT COSTS ACCORDING TO THE PRESENT COSTING SYSTEM Total number of labor hours: 0.5 x 7,000+ 1x 15,000+0.8x4,400-22,020 hours Monthly overhead costs Buying and handling costs 220,000 Machine set-up labor costs 19.920 Indirect production costs 180,000 Maintenance costs 45.600 120,000 Packaging and transportation costs Sales costs 120,000 Total 705,520 Indirect costs per labor hour 705,520/22,020 - 32.04 For each product, we calculate the following full product cost per unit (in C): Hair Dryer Per unit Coffee maker Component cost 8 10 12 6 Direct labor cost 1x 32.04 32.04 Overhead cost 0.5 x 32.04 16.02 54.04 Full product cost Selling price 30.02 41 58 Profit 10.98 3.96 Allocation of indirect costs: Food processor 11 9.6 0.8 x 32.04=25.63 46.23 75 28.77 31 APPENDIX 3: ACTIVITIES AND COST DRIVERS Cost driver Activities Contacting suppliers and placing number of suppliers contacted orders Purchasing and logistic department Handling of components for production line preparation number of types of components handled per machine set-up multiplied by the number of machine set-ups Planning and monitoring number of machine set-ups. production Production department Manufacturing the product number of machine hours Maintenance department Maintaining the equipment Product packaging Delivery department Delivering product to clients number of machine hours number of products packed number of deliveries number of new products launched on the market number of customers visited each month Product promotion Customer service department Client follow-up APPENDIX 4: TOTAL COST PER ACTIVITY Note: Managers from different departments were interviewed and operational data was gathered. This information was analyzed to determine the amount of resources consumed by each activity per month. Activities Contacting suppliers and placing orders Cost (in euros) 40,000 Handling of components for production line preparation 100,000 Planning and monitoring production 80,000 Manufacturing the product 180,000 Maintaining the equipment 45,600 Product packaging 20,000 Delivering product to clients 100,000 Product promotion 30,000 Client follow-up 90,000 32

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts