Question: READ CAREFULLY: Solve 3 problems given below on a white paper. Show your work clearly in each answer. Include the question numbers in your answers.

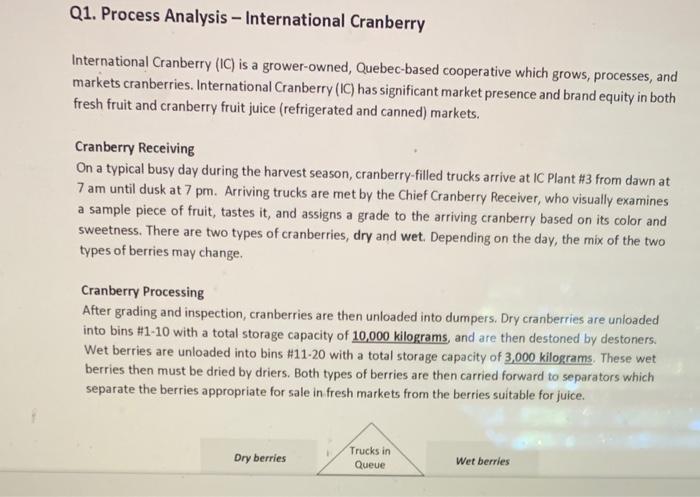

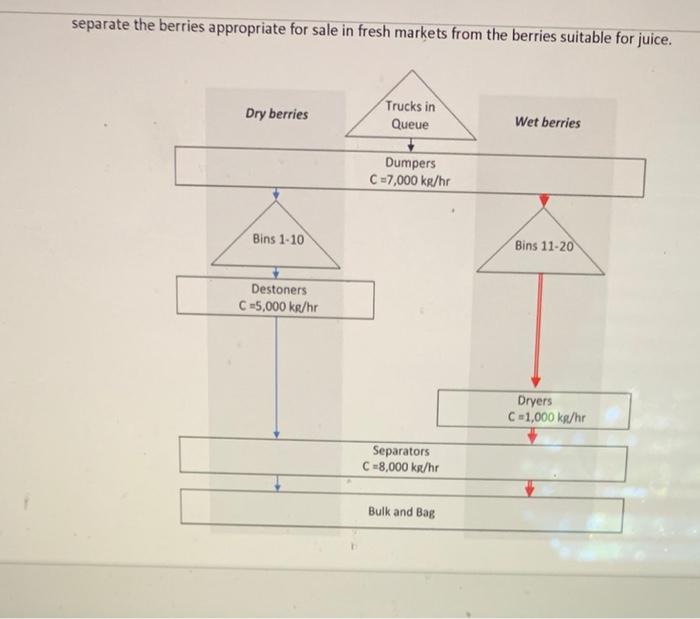

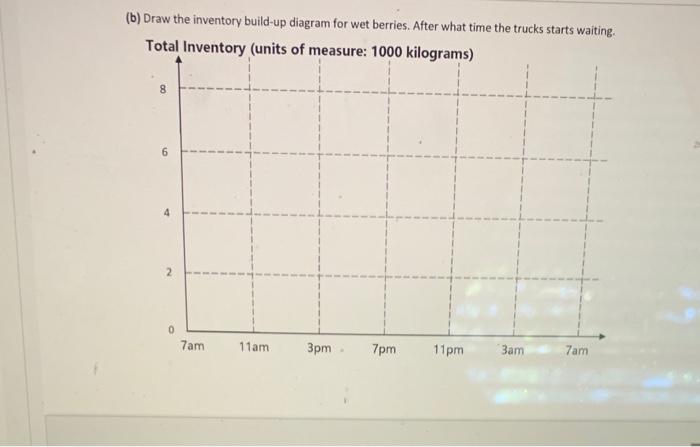

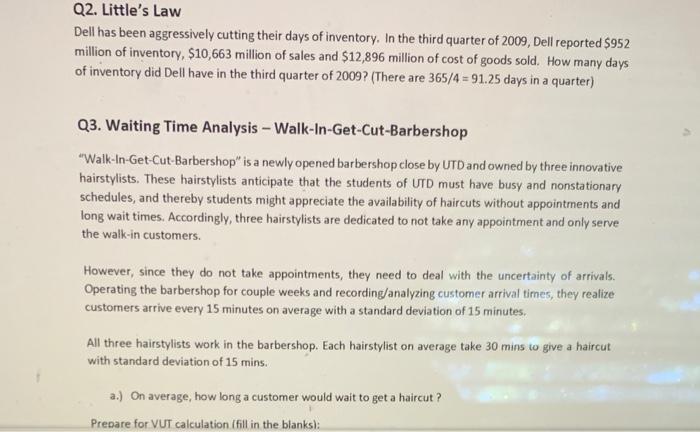

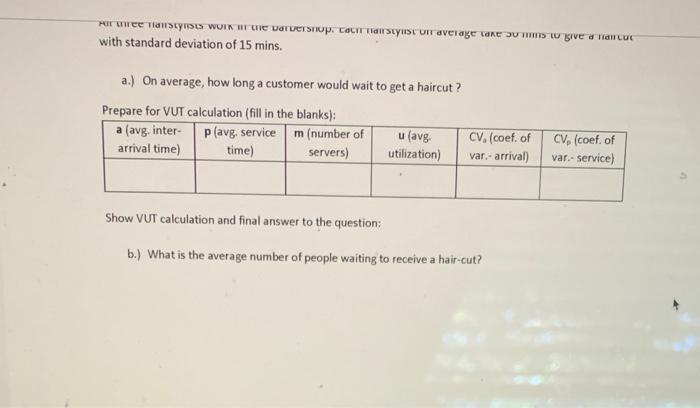

READ CAREFULLY: Solve 3 problems given below on a white paper. Show your work clearly in each answer. Include the question numbers in your answers. Scan your answers in a SINGLE PDF DOCUMENT (not doc, not jpeg, not png, not etc.) using your smart phone, email it to yourself and upload the document below. The last 10 minutes of the exam is given to you for scanning and uploading your answers. Do not WASTE this time on answering questions. Late submissions WILL NOT BE ACCEPTED. Taking pictures, capturing screen shots, downloading, or copying of exam questions is STRICTLY FORBIDDEN POINT DISTRIBUTION: Q1. Process Analysis (30 pts) Q2. Little's Law (20 pts) Q3. Waiting Time Analysis (30 pts) Q1. Process Analysis - International Cranberry International Cranberry (IC) is a grower-owned, Quebec-based cooperative which grows, processes, and markets cranberries. International Cranberry (IC) has significant market presence and brand equity in both fresh fruit and cranberry fruit juice (refrigerated and canned) markets. Cranberry Receiving On a typical busy day during the harvest season, cranberry-filled trucks arrive at IC Plant #3 from dawn at 7 am until dusk at 7 pm. Arriving trucks are met by the Chief Cranberry Receiver, who visually examines a sample piece of fruit, tastes it, and assigns a grade to the arriving cranberry based on its color and sweetness. There are two types of cranberries, dry and wet. Depending on the day, the mix of the two types of berries may change. Cranberry Processing After grading and inspection, cranberries are then unloaded into dumpers. Dry cranberries are unloaded into bins #1-10 with a total storage capacity of 10,000 kilograms, and are then destoned by destoners. Wet berries are unloaded into bins #11-20 with a total storage capacity of 3,000 kilograms. These wet berries then must be dried by driers. Both types of berries are then carried forward to separators which separate the berries appropriate for sale in fresh markets from the berries suitable for juice. Dry berries Trucks in Queue Wet berries separate the berries appropriate for sale in fresh markets from the berries suitable for juice. Dry berries Trucks in Queue Wet berries Dumpers C +7,000 kg/hr Bins 1-10 Bins 11-20 Destoners C -5,000 kg/hr Dryers C-1,000 kg/hr Separators C -8,000 kg/hr Bulk and Bag On a typical busy day, trucks arrive at the rate 10 every hour from 7:00 am to 7:00 pm. Assume that trucks arrive uniformly (i.e., no variability) and each truck carries exactly 200 kilograms of cranberries. The plant starts processing at 7:00 am. (a) Assume 25% of cranberries are dry and 75% of cranberries are wet. What are the hourly throughput rates of the dry berries and the wet berries from 7 am to 7 pm? What is the bottleneck? Throughput rate (dry) Throughput rate (wet) Bottleneck (wet) (b) Draw the inventory build-up diagram for wet berries. After what time the trucks starts waiting. Total Inventory (units of measure: 1000 kilograms) 8 (b) Draw the inventory build-up diagram for wet berries. After what time the trucks starts waiting. Total Inventory (units of measure: 1000 kilograms) 8 6 4 2 0 7am 11am 3pm 7pm 11pm 3am 7am Q2. Little's Law Dell has been aggressively cutting their days of inventory. In the third quarter of 2009, Dell reported $952 million of inventory, $10,663 million of sales and $12,896 million of cost of goods sold. How many days of inventory did Dell have in the third quarter of 2009? (There are 365/4 = 91.25 days in a quarter) Q3. Waiting Time Analysis - Walk-In-Get-Cut-Barbershop "Walk-In-Get-Cut-Barbershop" is a newly opened barbershop close by UTD and owned by three innovative hairstylists. These hairstylists anticipate that the students of UTD must have busy and nonstationary Schedules, and thereby students might appreciate the availability of haircuts without appointments and long wait times. Accordingly, three hairstylists are dedicated to not take any appointment and only serve the walk-in customers. However, since they do not take appointments, they need to deal with the uncertainty of arrivals. Operating the barbershop for couple weeks and recording/analyzing customer arrival times, they realize customers arrive every 15 minutes on average with a standard deviation of 15 minutes All three hairstylists work in the barbershop. Each hairstylist on average take 30 mins to give a haircut with standard deviation of 15 mins a.) On average, how long a customer would wait to get a haircut? Prepare for VUT calculation (fill in the blanks): Het Tasty WUER HIT THE WATERSHOP. COCISCUIT Verage Rems BVE TICE with standard deviation of 15 mins. a.) On average, how long a customer would wait to get a haircut ? Prepare for VUT calculation (fill in the blanks): a (avg. inter p (avg, service m (number of u (avg. arrival time) time) servers) utilization) CV. (coef. of var. arrival) CV. (coef. of var- service) Show VUT calculation and final answer to the question: b.) What is the average number of people waiting to receive a hair-cut? READ CAREFULLY: Solve 3 problems given below on a white paper. Show your work clearly in each answer. Include the question numbers in your answers. Scan your answers in a SINGLE PDF DOCUMENT (not doc, not jpeg, not png, not etc.) using your smart phone, email it to yourself and upload the document below. The last 10 minutes of the exam is given to you for scanning and uploading your answers. Do not WASTE this time on answering questions. Late submissions WILL NOT BE ACCEPTED. Taking pictures, capturing screen shots, downloading, or copying of exam questions is STRICTLY FORBIDDEN POINT DISTRIBUTION: Q1. Process Analysis (30 pts) Q2. Little's Law (20 pts) Q3. Waiting Time Analysis (30 pts) Q1. Process Analysis - International Cranberry International Cranberry (IC) is a grower-owned, Quebec-based cooperative which grows, processes, and markets cranberries. International Cranberry (IC) has significant market presence and brand equity in both fresh fruit and cranberry fruit juice (refrigerated and canned) markets. Cranberry Receiving On a typical busy day during the harvest season, cranberry-filled trucks arrive at IC Plant #3 from dawn at 7 am until dusk at 7 pm. Arriving trucks are met by the Chief Cranberry Receiver, who visually examines a sample piece of fruit, tastes it, and assigns a grade to the arriving cranberry based on its color and sweetness. There are two types of cranberries, dry and wet. Depending on the day, the mix of the two types of berries may change. Cranberry Processing After grading and inspection, cranberries are then unloaded into dumpers. Dry cranberries are unloaded into bins #1-10 with a total storage capacity of 10,000 kilograms, and are then destoned by destoners. Wet berries are unloaded into bins #11-20 with a total storage capacity of 3,000 kilograms. These wet berries then must be dried by driers. Both types of berries are then carried forward to separators which separate the berries appropriate for sale in fresh markets from the berries suitable for juice. Dry berries Trucks in Queue Wet berries separate the berries appropriate for sale in fresh markets from the berries suitable for juice. Dry berries Trucks in Queue Wet berries Dumpers C +7,000 kg/hr Bins 1-10 Bins 11-20 Destoners C -5,000 kg/hr Dryers C-1,000 kg/hr Separators C -8,000 kg/hr Bulk and Bag On a typical busy day, trucks arrive at the rate 10 every hour from 7:00 am to 7:00 pm. Assume that trucks arrive uniformly (i.e., no variability) and each truck carries exactly 200 kilograms of cranberries. The plant starts processing at 7:00 am. (a) Assume 25% of cranberries are dry and 75% of cranberries are wet. What are the hourly throughput rates of the dry berries and the wet berries from 7 am to 7 pm? What is the bottleneck? Throughput rate (dry) Throughput rate (wet) Bottleneck (wet) (b) Draw the inventory build-up diagram for wet berries. After what time the trucks starts waiting. Total Inventory (units of measure: 1000 kilograms) 8 (b) Draw the inventory build-up diagram for wet berries. After what time the trucks starts waiting. Total Inventory (units of measure: 1000 kilograms) 8 6 4 2 0 7am 11am 3pm 7pm 11pm 3am 7am Q2. Little's Law Dell has been aggressively cutting their days of inventory. In the third quarter of 2009, Dell reported $952 million of inventory, $10,663 million of sales and $12,896 million of cost of goods sold. How many days of inventory did Dell have in the third quarter of 2009? (There are 365/4 = 91.25 days in a quarter) Q3. Waiting Time Analysis - Walk-In-Get-Cut-Barbershop "Walk-In-Get-Cut-Barbershop" is a newly opened barbershop close by UTD and owned by three innovative hairstylists. These hairstylists anticipate that the students of UTD must have busy and nonstationary Schedules, and thereby students might appreciate the availability of haircuts without appointments and long wait times. Accordingly, three hairstylists are dedicated to not take any appointment and only serve the walk-in customers. However, since they do not take appointments, they need to deal with the uncertainty of arrivals. Operating the barbershop for couple weeks and recording/analyzing customer arrival times, they realize customers arrive every 15 minutes on average with a standard deviation of 15 minutes All three hairstylists work in the barbershop. Each hairstylist on average take 30 mins to give a haircut with standard deviation of 15 mins a.) On average, how long a customer would wait to get a haircut? Prepare for VUT calculation (fill in the blanks): Het Tasty WUER HIT THE WATERSHOP. COCISCUIT Verage Rems BVE TICE with standard deviation of 15 mins. a.) On average, how long a customer would wait to get a haircut ? Prepare for VUT calculation (fill in the blanks): a (avg. inter p (avg, service m (number of u (avg. arrival time) time) servers) utilization) CV. (coef. of var. arrival) CV. (coef. of var- service) Show VUT calculation and final answer to the question: b.) What is the average number of people waiting to receive a hair-cut