Question: Refeer to the Case Study and Please answer question 9, 10, 11 please read the whole document, and when assissting please make references from the

Refeer to the Case Study and Please answer question 9, 10, 11

please read the whole document, and when assissting please make references from the document, and please assisst with questions 9,10,11

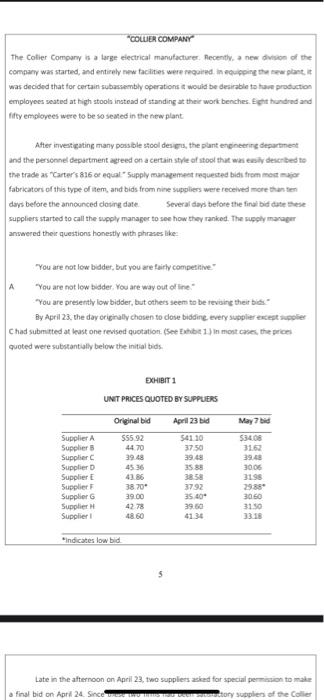

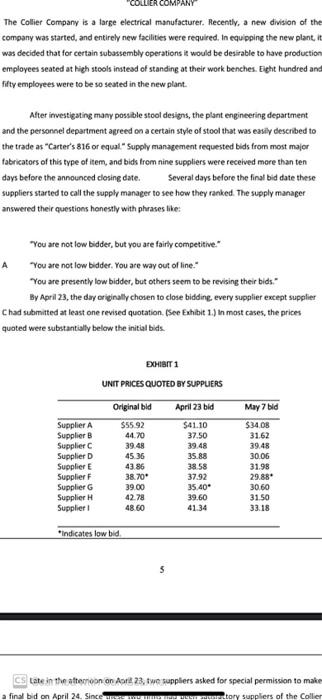

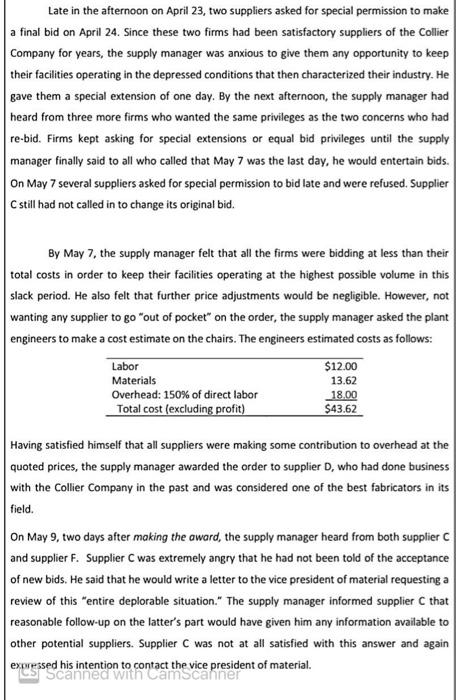

What are operational practices? Operating practices refers to the methods of operating a business or providing a Service includes the daily practices that a business observed in order to ensure safety of process and health of employees, Finances, training communication, equipment, employees, and management of buildings suppliers and stakeholders are all on the task list for operation managers can become an overwhelming to-do list. Learning and implementing best practices from experienced operation managers can prevent mistakes, maintain operations in flow and keep you organization profitable and productive OPERATIONS MANAGEMENT IN PRACTICE of all the business functions, operations are the most diverse in terms of the task performed If you consider all the issues involved in managing a transformation process, you can see that operations managers are never bored. Who are operations managers and what do they do? The head of the operations function in a company way holds the title of vice president of operation, vice president of manufacturing, V.P., or director of supply chain operations and generally reports directly to the president or chief operating officer Below the president level are midlevel managers, manufacturing manager, operations Manager al control manager, plant manager, and others. Below these managers are a variety of positions, such as Quality specialist, production analyst inventory analyst and production Supervisor. These people perform a variety of functions analyzing production problems, developing forecast making plans for new products, measuring quality, monitoring inventory and developing employee schedules. Thus, there are many job opportunities in operations Management levels of the company. In addition, operations jobs tend to offer the resting work, and excellent opportunities for advancement. Many corporate CEDs today have come through the ranks of operations. For example, the third president and CEO of Wal-Mart from January 2000 to January 2009. H. Lee Scott, came from a background in operations and logistics Best practices in operations Management Most businesses experience operational issues that can be resolved through the introduction of best practice methods. These include, for examples quality management standards and systems stock control delivery and supply chain management purchasing and ordering information management You can identity which operational areas will benefit from best practice bar benchmarking internal analysis reviewing appropriate national and international standards What is best practice in business? Best practice in business means finding and using the best war of working to achieve your business goals It involves keeping up to date with the ways that successful businesses operate in your sector and others and includes measurine your ways of working against those used by the market leaders Benchmarking best practice Applying best practice meard learning from and through the experence of others. One way doing this is through benchmarking which allows you to compare your business with other successful businesses. This lets you highlight areas where your business could proe. See how to benchmark your business performance Standards for best business practice Standards are found specifications or benchmarks, which are established by dependent bodies such as the British Standards Institution (850flink is external), BS develops to man types of standards technical standards precise specifications against which you can measure they of your product, service or processes 2 management standards - models for achieving best business and organisation practice Conforming to the right standard will enable you to apply best practice across your business it will allow you to work against objective criteria to achieve manufacturing or rece quality See how to make beste standards Benefits of best practice for businesses by following best practices, you can become more competitie increase sales and develop new markets reduce costs and become more efficient improve the skills of your woriforce use technology more effectively reduce waste and improve quality respond more quickly to innovations in your sector Defining a Best Practice is a technique or methodology that through experience and research has proven to rekably lead to a desired result. A commitment to using the best practices and a commitment to using all the knowledge and technology at one's disposal to ensure success The term is used frequently in the fields of health care government in the education system, project management, hardware and software product development and elsewhere Defining Operations Management Operation management refers to the administration of business practices to create the highest level of etticiency possible within an organization Operation managements concerned with converting materials and labor into goods and services as es possible to maximize the profit of an organization Operations Management is chiefly concerned with planning organising and song the contexts of production, manufacturing or the provision of services. As such a focused, ensuring that an organisation successfully turn inputs to putstient manner. The inputs themselves could represent anything from materials comentand technology to human resources such as staff or workers 3 Best Practices for increasing Productivity in How Can Functions of the Operations Manager increase productivity "Ah cerations manager takes on tasks designed to improve productivity and assist in the growth of the organization. Some of the functions directly affected by the operation manager purchasing manufacturing shipping packaging human resources company finance and computer support. To understand the job a production manager is required to do, you need to understand how the functions of an operation manager increase product Operations Managers are responsible for and work in conjunction with many aspects of the company, their soset must reflect both a breadth and death of knowledge from myriad of areas Root highlights several best practices used by operational managers to create productivity, decrease waste, and generate profit 1. Equipment Upgrades One of the responsibilities of an operations Manager is to analyse work functions and determine what equipment upgrades would improve productty 2. Communication Coordination improved communication within an organisation can increase productivity, When Information is sent from one department to the und accurately, it can speed up the pace at which the company can operate and ensures that necessary parties get the information they need to be productive 3. Revenue Collection - The operation manager is in charge of billing and revenue collection By analyzing revenue collection procedures, the operations manager can create ways of collecting revenue quickly to make sure the company has cashion hand 4. Training Operational manager work with the human resources department and departmental managers to develop more efficient ways for employees to do the job Analyzing work functions is one of the many tasks that an operation manager performs each tay Those working in operations Management must engage in all types of criticals with a particular emphasis on effective decision-making to meet the needs of stakeholders and the goals of the company, Bringing innovation and cutting edge best practices to the sot quality management, inventory control, delivery, supply chain and information management is what makes the difference between a marginally successful company and a company that dominates their share of the marketplace "GOLLER COMPANY The Colier Company is a large electrical manufacturer. Recently, a new division of the company was started and entirely new facilities were required in cuping the new plant it was decided that for certain subassembly operations it would be desirable to reproduction employees seated at high stools instead of standing at their work benches. Et hundred and fifty employees were to be so seated in the new plant After investigating many possible tool designs, the plant engineering department and the personnel department agreed on a certain style of stool that was easily described to the trade as Carter's 816 or equalSupply management requested bids from most fabricators of this type of item, and bids from nine suppliers were received more than en days before the announced dosing date. Several days before the final bid date these suppliers started to call the supply manager to see how they raniced. The supply manager answered their questions honestly with phrases like "You are not low bidder, but you are fairly competitive "You are not low bidder. You are way out of time "You are presently low bidder, but othes seem to be revsing their bis By April 23, the day originally chosen to close bidding every supplier excest spolie Chad submitted at least one revised quotation. (Seebet 1. in most cases, the prices quoted were substantially below the initial bids May 7 bid $3406 Supplier Suppliers Supplier Supplier Supplier Supplier Supplier Supplier Supplier EXHIBIT 1 1 UNIT PRICES QUOTED BY SUPPLIERS Original bid April 23 bid 555 92 54110 4470 3750 39.48 3943 45 36 35 88 43.86 38:58 38.70 3792 39.00 35.400 4278 39.50 48.60 39.28 3006 3198 29.884 3060 3150 3318 indicates low bid Late in the afternoon on April 23, two suppliers asked for special permission to make afinal bid on April 24. Since tory suples of the Colle Late in the afternoon on April 23. two suppliers asked for special permission to make a final bid on April 24 Since these two firms had been satisfactory suppliers of the Collier Company for years, the supply manager was anxious to give them any opportunity to keep their facilities operating in the depressed conditions that the charactered their industry. He gave them a special extension of one day. By the next afternoon, the supply manager had heard from three more firms who wanted the same privileges as the two concerns who had re bid, Firme kept asking for special extensions or equal bid wees the suo manager finally said to all who called that May 7 was the last day, he would entertain bide On May 7several suppliers asked for special permission to bid late and were retused Split C still had not called in to change its original bid Hy May 7, the supply manager felt that all the firms were bidding at less than their total costs in order to keep their facilities operating at the highest possible volumen this stack period. He also felt that further price adjustments would be negle. However, not wanting any supplier to go out of pocket on the order the supply manager asked the plant engineers to make a cost estimate on the chairs. The engineers estimated costs as follows Labor $12.00 Materiais Overhead: 150% of direct labor 18.00 Total cost (excluding profit) $43.62 Having satisfied himself that all suppliers were making some contribution to overhead at the quoted prices, the supply manager awarded the order to supplier who had done business with the Collier Company in the past and was considered one of the best fabricators hield On May 9, two days after making the award the supply manager heard from both supplier and supplier F. Supplier C was extremely angry that he had not been told of the acceptance of new bids. He said that he would write a letter to the vice president of material desting a review of this entre deplorable situation. The supply manager informed pole that reasonable follow up on the latter's part would have given him any information able to other potential suppliers. Suppler was not satisfied with this and again expressed his intention to contact the vice president of material Supplier F asked why the supply manager had requested bids at all if his "mind had been made up all along." Supplier F said that the order should have gone to the lowest bidder who could provide the object desired. He said he could meet the specifications and could deliver to any schedule supplier D could meet. He demanded the order, and when the supply manager informed supplier F that "final selection of the supplier is entirely my province," the supplier raged that he would "spread the word to the trade" and would write the Collier Company president, who "should know of such favouritism and incompetence." He further stated that he even suspected that money had passed hands for this order. The supply manager was upset by these calls and did not enjoy his supper on May 9. 9. In relation to defining operation management, do you think that the administration of this tender equid a fair business practice? Discuss (5 marks) 10. Discuss "information management "as one of the best OMP in relation to how Collier tender was awarded (5 marks) 11. What will be Collier's benefits if the new operation plant achieves its objective? (5 marks) What are operational practices? Operating practices refers to the methods of operating a business or providing a service. It includes the daily practices that a business observes in order to ensure safety of process and health of employees, Finances, training, communication, equipment, employees, and management of buildings, suppliers and stakeholders are all on the task list for operations managers. It can become an overwhelming to-do list. Learning and implementing best practices from experienced operations managers can prevent mistakes, maintain operations in flow, and keep your organization profitable and productive. OPERATIONS MANAGEMENT IN PRACTICE of all the business functions, operations are the most diverse in terms of the tasks performed. If you consider all the issues involved in managing a transformation process, you can see that operations managers are never bored. Who are operations managers and what do they do? The head of the operations function in a company usually holds the title of vice president of operations, vice president of manufacturing, V.P., or director of supply chain operations and generally reports directly to the president or chief operating officer. Below the vice president level are midlevel managers: manufacturing manager, operations manager, quality control manager, plant manager, and others. Below these managers are a variety of positions, such as quality specialist, production analyst, inventory analyst, and production supervisor. These people perform a variety of functions: analyzing production problems, developing forecasts, making plans for new products, measuring quality, monitoring inventory, and developing employee schedules. Thus, there are many job opportunities in operations management at all levels of the company. In addition, operations jobs tend to offer high salaries, interesting work, and excellent opportunities for advancement. Many corporate CEOs today have come through the ranks of operations. For example, the third president and CEO of Wal-Mart from January 2000 to January 2009, H. Lee Scott, came from a background in operations and lorscanned with CamScanner Best practices in operations Management Most businesses experience operational issues that can be resolved through the introduction of best practice methods. These include, for example: quality management standards and systems stock control, delivery and supply chain management purchasing and ordering information management You can identify which operational areas will benefit from best practice by: benchmarking internal analysis reviewing appropriate national and international standards What is best practice in business? Best practice in business means finding - and using - the best ways of working to achieve your business goals. It involves keeping up to date with the ways that successful businesses operate in your sector and others and includes measuring your ways of working against those used by the market leaders. Benchmarking best practice Applying best practice means learning from and through the experience of others. One way of doing this is through benchmarking, which allows you to compare your business with other successful businesses. This lets you highlight areas where your business could improve. See how to benchmark your business performance. Standards for best business practice Standards are fixed specifications or benchmarks, which are established by independent bodies such as the British Standards Institution (B) (link is external). BSI develops two main types of standards: cs tecanned with CamScanner technical standards - precise specifications against which you can measure the quality of your product, service or processes management standards - models for achieving best business and organisational practice Conforming to the right standards will enable you to apply best practice across your business. It will allow you to work against objective criteria to achieve manufacturing or service quality. See how to make best use of standards. Benefits of best practice for businesses By following best practices, you can: become more competitive increase sales and develop new markets reduce costs and become more efficient improve the skills of your workforce use technology more effectively reduce waste and improve quality respond more quickly to innovations in your sector Defining a Best Practice It is a "technique or methodology that, through experience and research, has proven to reliably lead to a desired result. A commitment to using the best practices in any field is a commitment to using all the knowledge and technology at one's disposal to ensure success. The term is used frequently in the fields of health care, government administration, the education system, project management, hardware and software product development, and elsewhere." Defining Operations Management Operations management refers to the administration of business practices to create the highest level of efficiency possible within an organization. Operations management is concerned with converting materials and labor into goods and services as efficiently as possible to maximize the profit of an organization. Operations management is "chiefly concerned with planning, organizing and supervising in the contexts of production, manufacturing or the provision of services. As such, it is delivery- focused, ensuring that an organization successfully turns inputs to outputs in an efficient mander. The inputs themselves. could represent anything from materials, equipment and technology to human resources such as staff or workers." Best Practices for Increasing Productivity In How Can Functions of the Operations Manager Increase Productivity: "An operations manager takes on tasks designed to improve productivity and assist in the growth of the organization. Some of the functions directly affected by the operations manager are purchasing, manufacturing, shipping, packaging, human resources, company finance, and computer support. To understand the job a production manager is required to do, you need to understand how the functions of an operations manager increase productivity." Operations Managers are responsible for, and work in conjunction with, many aspects of the company, their skill-set must reflect both a breadth and depth of knowledge from a myriad of areas. Root highlights several best practices used by operational managers to increase productivity, decrease waste, and generate profit. 1. Equipment Upgrades - One of the responsibilities of an operations manager is to analyze work functions and determine what equipment upgrades would improve productivity. 2. Communication Coordination Improved communication within an organization can increase productivity. When information is sent from one department to another quickly and accurately, it can speed up the pace at which the company can operate and ensures that all necessary parties get the information they need to be productive. 3. Revenue Collection - The operations manager is in charge of billing and revenue collection. By analyzing revenue collection procedures, the operations manager can create ways of collecting revenue quickly to make sure the company has cash on hand. 4. Training - Operational managers work with the human resources department and departmental managers to develop more efficient ways for employees to do their jobs. Analyzing work functions is one of the many tasks that an operations manager performs each day. Those working in operations management must engage in all types of critical analysis with a particular emphasis on effective decision-making to meet the needs of stakeholders and the goals of the company. Bringing innovation and cutting-edge best practices to the areas of quality management, inventory control, delivery, supply chain, and information management, is what makes the difference duwwates their share of the marketplace. Costestant daterence between a marginally successful company and a company that The Collier Company is a targe electrical manufacturer. Recently, a new division of the company was started and entirely new facilities were required. In equipping the new plant. It was decided that for certain subassembly operations it would be desirable to have production employees seated at high stools instead of standing at their work benches. Eight hundred and fifty employees were to be so seated in the new plant Alter investigating many possible stool designs, the plant engineering department and the personnel department agreed on a certain style of stool that was easily described to the trade as "Carter's 816 or equat.Supply management requested bids from most major fabricators of this type of item, and bids from nine suppliers were received more than ten days before the announced closing date. Several days before the final bid date these suppliers started to call the supply manager to see how they ranked. The supply manager answered their questions honestly with phrases like: You are not low bidder, but you are fairly competitive." A You are not low bidder. You are way out of line. You are presently low bidder, but others seem to be revising their bids. By April 23, the day originally chosen to close bidding every supplier except supplier Chad submitted at least one revised quotation. (See Exhibit 1.) in most cases, the prices quoted were substantially below the initial bids EXHIBIT 1 UNIT PRICES QUOTED BY SUPPLIERS Original bid April 23 bid May 7 bid Supplier A Supplier Supplier Supplier D Supplier Supplier Supplier Supplier Supplier $55 92 44.70 39.48 45.36 43.86 38.70 39.00 42.78 $41.10 37.50 39.48 35.88 38 58 37.92 35.40* 39.60 41.34 $34.08 31.62 39.48 30.06 31.98 29.88 30.60 31.50 33.18 48.60 Indicates low bid 5 CS tate in the afternoon on April, 23, we suppliers asked for special permission to make a final bid on April 24. Since Story suppliers of the Collier Late in the afternoon on April 23, two suppliers asked for special permission to make a final bid on April 24. Since these two firms had been satisfactory suppliers of the Collier Company for years, the supply manager was anxious to give them any opportunity to keep their facilities operating in the depressed conditions that then characterized their industry. He gave them a special extension of one day. By the next afternoon, the supply manager had heard from three more firms who wanted the same privileges as the two concerns who had re-bid. Firms kept asking for special extensions or equal bid privileges until the supply manager finally said to all who called that May 7 was the last day, he would entertain bids. On May 7 several suppliers asked for special permission to bid late and were refused. Supplier C still had not called in to change its original bid. By May 7, the supply manager felt that all the firms were bidding at less than their total costs in order to keep their facilities operating at the highest possible volume in this slack period. He also felt that further price adjustments would be negligible. However, not wanting any supplier to go out of pocket" on the order, the supply manager asked the plant engineers to make a cost estimate on the chairs. The engineers estimated costs as follows: Labor $12.00 Materials 13.62 Overhead: 150% of direct labor 18.00 Total cost (excluding profit) $43.62 Having satisfied himself that all suppliers were making some contribution to overhead at the quoted prices, the supply manager awarded the order to supplier D, who had done business with the Collier Company in the past and was considered one of the best fabricators in its field On May 9, two days after making the award, the supply manager heard from both supplier and supplier F. Supplier C was extremely angry that he had not been told of the acceptance of new bids. He said that he would write a letter to the vice president of material requesting a review of this entire deplorable situation." The supply manager informed supplier C that reasonable follow-up on the latter's part would have given him any information available to other potential suppliers. Supplier C was not at all satisfied with answer and again expressed intention Scanneden to contact the vice president of material, Supplier F asked why the supply manager had requested bids at all if his "mind had been made up all along." Supplier F said that the order should have gone to the lowest bidder who could provide the object desired. He said he could meet the specifications and could deliver to any schedule supplier D could meet. He demanded the order, and when the supply manager informed supplier F that "final selection of the supplier is entirely my province," the supplier raged that he would "spread the word to the trade" and would write the Collier Company president, who "should know of such favouritism and incompetence." He further stated that he even suspected that money had passed hands for this order. scanned with Camscannees The supply manager was upset by these calls and did not enjoy his supper on May 9. 9. In relation to defining operation management, do you think that the administration of this tender equid a fair business practice? Discuss (5 marks) 10. Discuss "information management "as one of the best OMP in relation to how Collier tender was awarded (5 marks) 11. What will be Collier's benefits if the new operation plant achieves its CS Scanned with CamScanner objective