Question: regarding this case study , i calculated the required capital recovery for each option in order to calculate the unit cost , laser option has

regarding this case study , i calculated the required capital recovery for each option in order to calculate the unit cost , laser option has minimum unit cost ( Recommended to be selected ). however my question is that ,what if ford decide to go with the laser blanking ,it will take 6 months to get up to the required production volume.What option should ford excersise to satisfy the production need during this start up period?

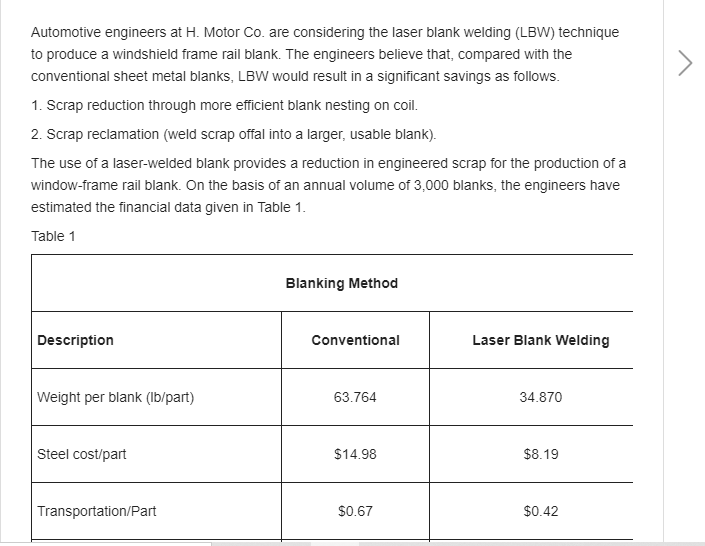

Automotive engineers at H. Motor Co. are considering the laser blank welding (LBW) technique to produce a windshield frame rail blank. The engineers believe that compared with the conventional sheet metal blanks, LBW would result in a significant savings as follows. 1. Scrap reduction through more efficient blank nesting on coil. 2. Scrap reclamation (weld scrap offal into a larger, usable blank). The use of a laser-welded blank provides a reduction in engineered scrap for the production of a window-frame rail blank. On the basis of an annual volume of 3,000 blanks, the engineers have estimated the financial data given in Table 1. Table 1 Blanking Method Description Conventional Laser Blank Welding Weight per blank (lb/part) 63.764 34.870 Steel cost/part $14.98 $8.19 Transportation/Part $0.67 $0.42Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts