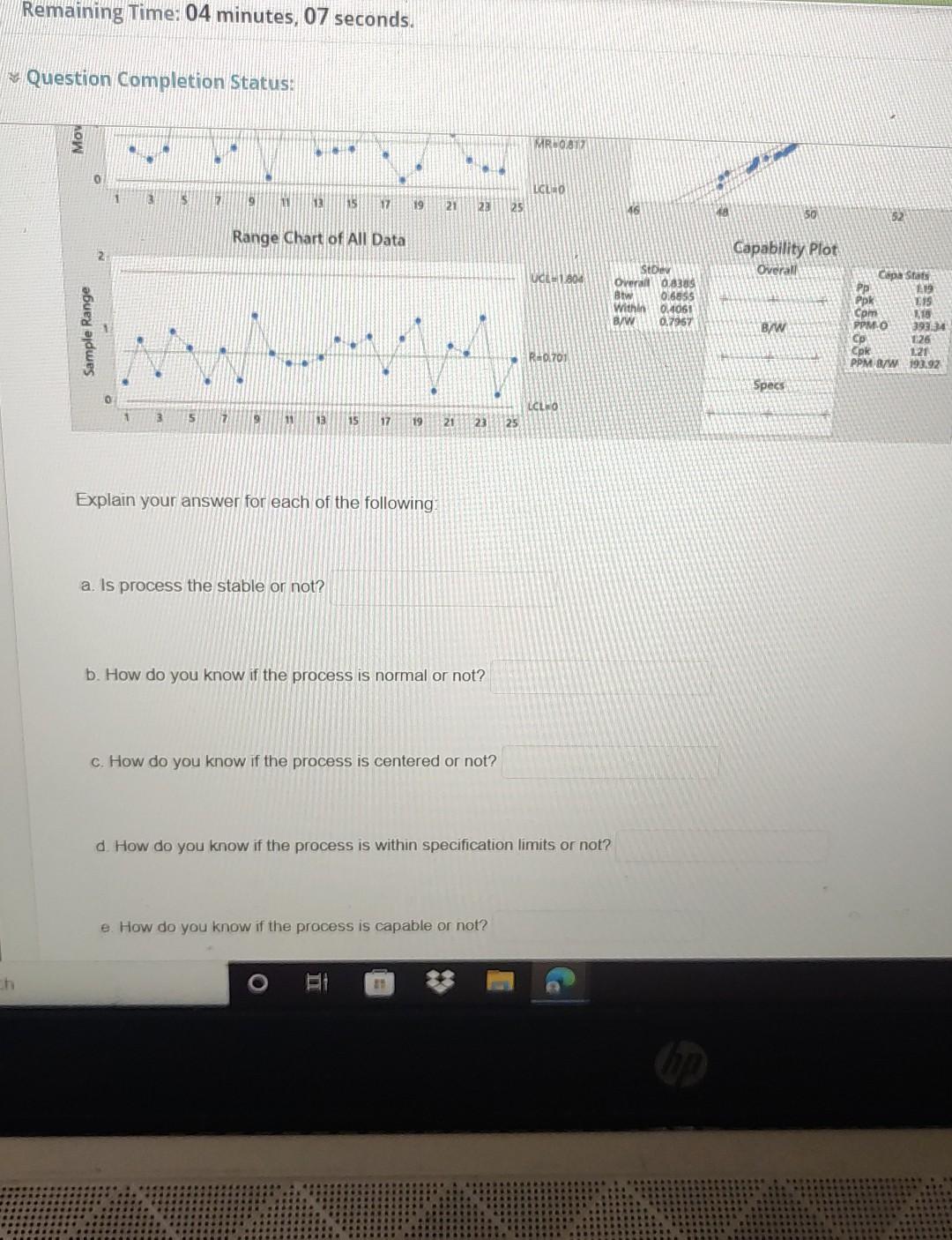

Question: Remaining Time: 04 minutes, 07 seconds. Question Completion Status: HO MR0017 0 1 3 S 17 1937 19 LGURO 25 21 23 26 50 52

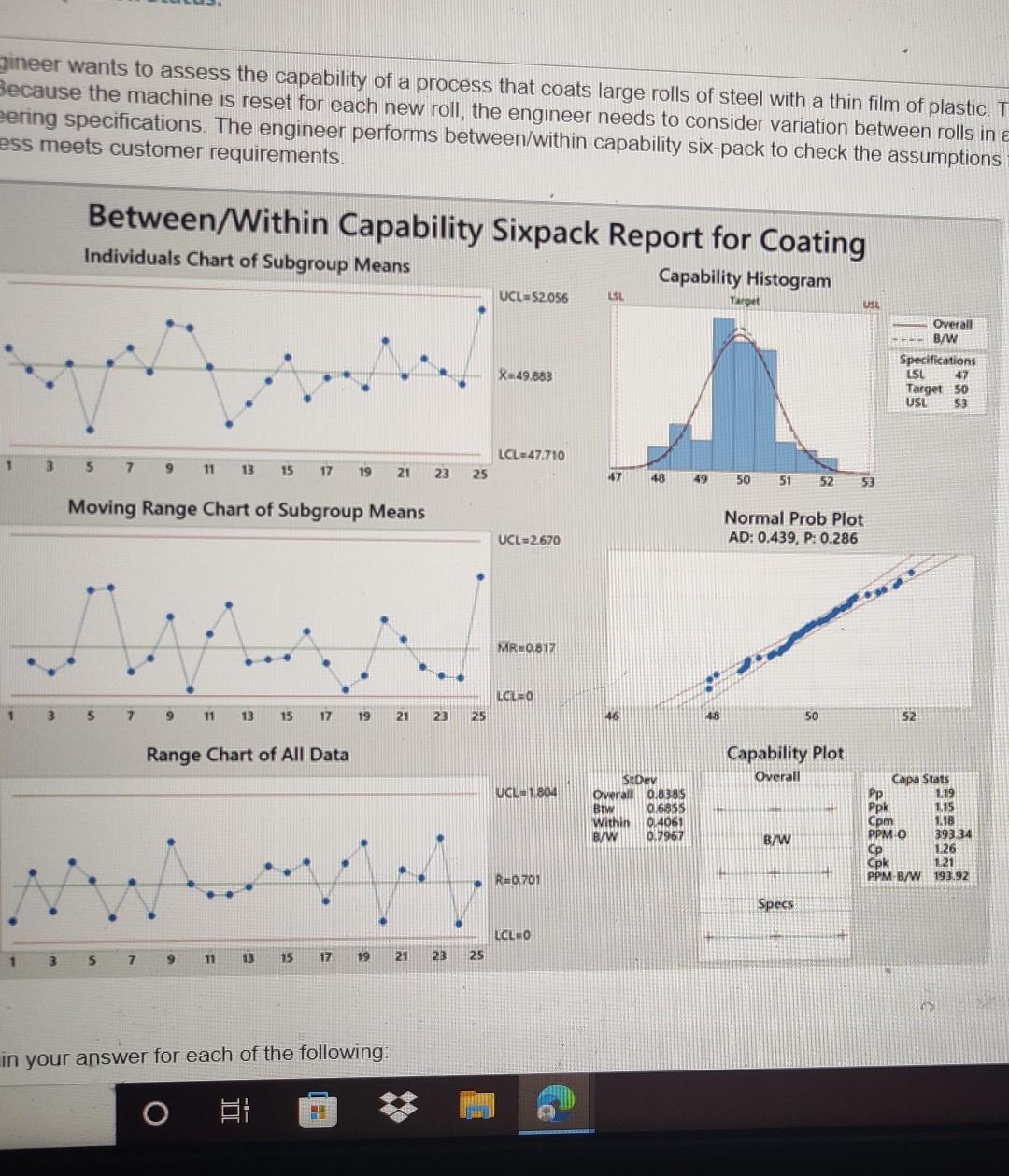

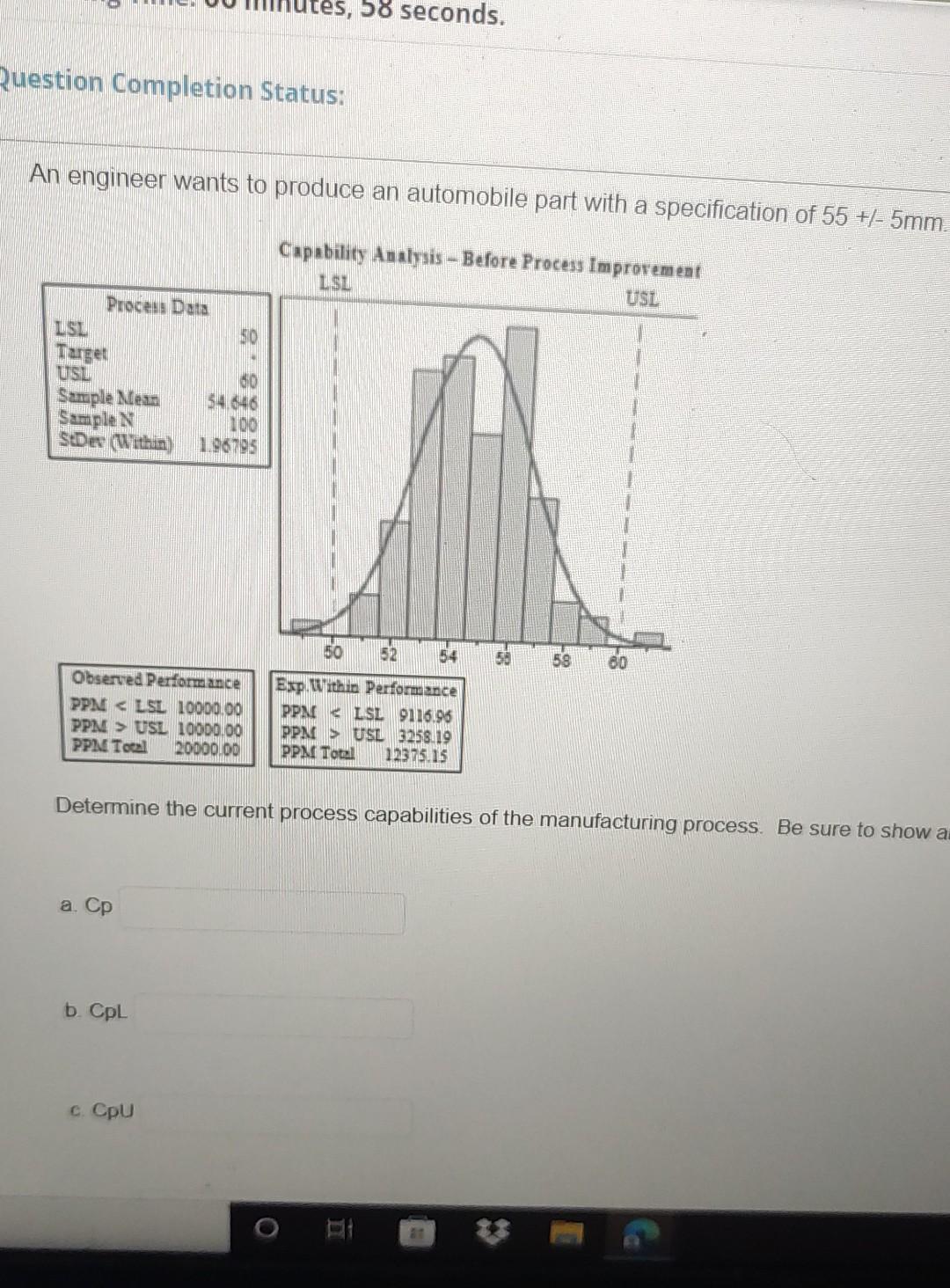

Remaining Time: 04 minutes, 07 seconds. Question Completion Status: HO MR0017 0 1 3 S 17 1937 19 LGURO 25 21 23 26 50 52 Range Chart of All Data 2 Capability Plot Overall Udth1 804 SED Overall 0.8386 Btw 0.6855 Within 0.4061 B/W 0.7957 Sample Range Capa Stats Pp 1.19 Ppk L15 Com 1.18 PPM O 39334 126 pk 121 PPM B/W 193.92 B/W R=0.701 . Specs 0 LCLHO 3 5 7 9 11 13 15 17 19 21 23 25 Explain your answer for each of the following a. Is process the stable or not? b. How do you know if the process is normal or not? c. How do you know if the process is centered or not? d How do you know if the process is within specification limits or not? e. How do you know if the process is capable or not? sh gineer wants to assess the capability of a process that coats large rolls of steel with a thin film of plastic. T Because the machine is reset for each new roll, the engineer needs to consider variation between rolls in a Pering specifications. The engineer performs between/within capability six-pack to check the assumptions ess meets customer requirements Between/Within Capability Sixpack Report for Coating Individuals Chart of Subgroup Means Capability Histogram UCL52056 LSL Target USU Overall - B/W Specifications LSL 47 Target 50 USL 53 X49.883 4710 1 3 5 7 9 11 13 15 17 19 21 23 25 07 48 49 50 51 52 53 Moving Range Chart of Subgroup Means Normal Prob Plot AD: 0.439, P: 0.286 UCL=2.670 MR.0.817 .. LCLEO 3 5 7 9 11 13 15 17 19 21 23 25 46 50 52 Range Chart of All Data Capability Plot Overall UC1804 Stev Overall 0.8385 Btw 0.6855 Within 0.4061 0.7967 Capa Stats Pp 119 Ppk 1.15 Cpm 1.18 PPM O 393.34 Cp 1.26 Cpk 121 PPM-B/W 193.92 B/W B/W R=0.701 Specs LCLHO S 7 9 1 11 13 15 17 19 21 23 25 in your answer for each of the following: 58 seconds. Question Completion Status: An engineer wants to produce an automobile part with a specification of 55 +/- 5mm. Capability Analysis - Before Process Improvement LSL USL Process Data LSL Target USL Sample Nenn 154.646 Sample N 100 StDer (Within 1.98795 50 52 54 58 00 Observed Performance PPM

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock