Question: Roedel Electronics produces tablet computer accessories, including integrated keyboard tablet stands that connect a keyboard to a tablet device and hold the device at a

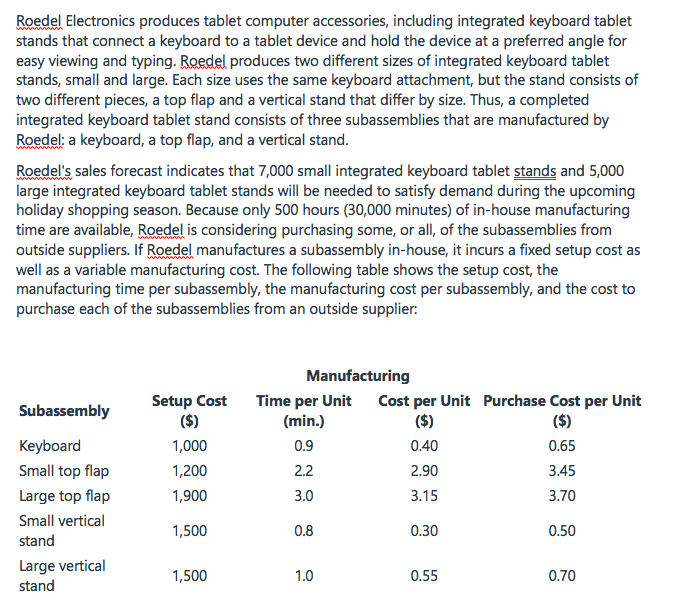

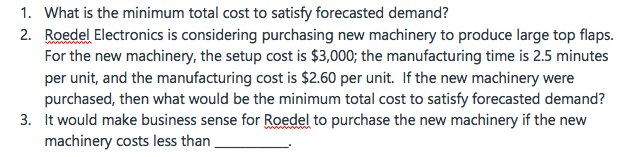

Roedel Electronics produces tablet computer accessories, including integrated keyboard tablet stands that connect a keyboard to a tablet device and hold the device at a preferred angle for easy viewing and typing. Roedel produces two different sizes of integrated keyboard tablet stands, small and large. Each size uses the same keyboard attachment, but the stand consists of two different pieces, a top flap and a vertical stand that differ by size. Thus, a completed integrated keyboard tablet stand consists of three subassemblies that are manufactured by Roedel: a keyboard, a top flap, and a vertical stand. Roedel's sales forecast indicates that 7,000 small integrated keyboard tablet stands and 5,000 large integrated keyboard tablet stands will be needed to satisfy demand during the upcoming holiday shopping season. Because only 500 hours (30,000 minutes) of in-house manufacturing time are available, Roedel is considering purchasing some, or all of the subassemblies from outside suppliers. If Roedel manufactures a subassembly in-house, it incurs a fixed setup cost as well as a variable manufacturing cost. The following table shows the setup cost, the manufacturing time per subassembly, the manufacturing cost per subassembly, and the cost to purchase each of the subassemblies from an outside supplier: Subassembly Keyboard Small top flap Large top flap Small vertical stand Large vertical stand Setup Cost ($) 1,000 1,200 1,900 Manufacturing Time per Unit Cost per Unit Purchase Cost per Unit (min.) ($) ($) 0.9 0.40 0.65 2.2 2.90 3.45 3.0 3.15 3.70 1,500 0.8 0.30 0.50 1,500 1.0 0.55 0.70 1. What is the minimum total cost to satisfy forecasted demand? 2. Roedel Electronics is considering purchasing new machinery to produce large top flaps. For the new machinery, the setup cost is $3,000; the manufacturing time is 2.5 minutes per unit, and the manufacturing cost is $2.60 per unit. If the new machinery were purchased, then what would be the minimum total cost to satisfy forecasted demand? 3. It would make business sense for Roedel to purchase the new machinery if the new machinery costs less than