Question: Rogers, Inc., is considering replacing its existing assembly line with a new upgraded model. The CEO of the company, John Rogers, makes $150,000 a year

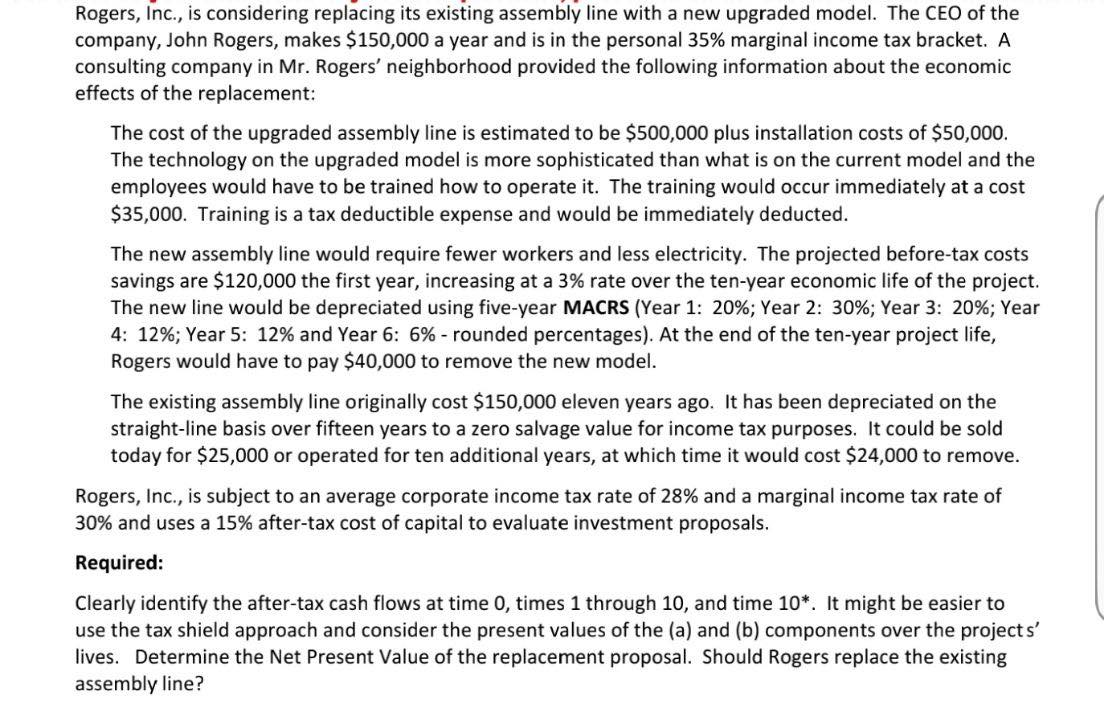

Rogers, Inc., is considering replacing its existing assembly line with a new upgraded model. The CEO of the company, John Rogers, makes $150,000 a year and is in the personal 35% marginal income tax bracket. A consulting company in Mr. Rogers' neighborhood provided the following information about the economic effects of the replacement: The cost of the upgraded assembly line is estimated to be $500,000 plus installation costs of $50,000. The technology on the upgraded model is more sophisticated than what is on the current model and the employees would have to be trained how to operate it. The training would occur immediately at a cost $35,000. Training is a tax deductible expense and would be immediately deducted. The new assembly line would require fewer workers and less electricity. The projected before-tax costs savings are $120,000 the first year, increasing at a 3% rate over the ten-year economic life of the project. The new line would be depreciated using five-year MACRS (Year 1: 20%; Year 2: 30%; Year 3: 20%; Year 4: 12%; Year 5: 12% and Year 6: 6% - rounded percentages). At the end of the ten-year project life, Rogers would have to pay $40,000 to remove the new model. The existing assembly line originally cost $150,000 eleven years ago. It has been depreciated on the straight-line basis over fifteen years to a zero salvage value for income tax purposes. It could be sold today for $25,000 or operated for ten additional years, at which time it would cost $24,000 to remove. Rogers, Inc., is subject to an average corporate income tax rate of 28% and a marginal income tax rate of 30% and uses a 15% after-tax cost of capital to evaluate investment proposals. Required: Clearly identify the after-tax cash flows at time 0, times 1 through 10, and time 10*. It might be easier to use the tax shield approach and consider the present values of the (a) and (b) components over the projects lives. Determine the Net Present Value of the replacement proposal. Should Rogers replace the existing assembly line? Rogers, Inc., is considering replacing its existing assembly line with a new upgraded model. The CEO of the company, John Rogers, makes $150,000 a year and is in the personal 35% marginal income tax bracket. A consulting company in Mr. Rogers' neighborhood provided the following information about the economic effects of the replacement: The cost of the upgraded assembly line is estimated to be $500,000 plus installation costs of $50,000. The technology on the upgraded model is more sophisticated than what is on the current model and the employees would have to be trained how to operate it. The training would occur immediately at a cost $35,000. Training is a tax deductible expense and would be immediately deducted. The new assembly line would require fewer workers and less electricity. The projected before-tax costs savings are $120,000 the first year, increasing at a 3% rate over the ten-year economic life of the project. The new line would be depreciated using five-year MACRS (Year 1: 20%; Year 2: 30%; Year 3: 20%; Year 4: 12%; Year 5: 12% and Year 6: 6% - rounded percentages). At the end of the ten-year project life, Rogers would have to pay $40,000 to remove the new model. The existing assembly line originally cost $150,000 eleven years ago. It has been depreciated on the straight-line basis over fifteen years to a zero salvage value for income tax purposes. It could be sold today for $25,000 or operated for ten additional years, at which time it would cost $24,000 to remove. Rogers, Inc., is subject to an average corporate income tax rate of 28% and a marginal income tax rate of 30% and uses a 15% after-tax cost of capital to evaluate investment proposals. Required: Clearly identify the after-tax cash flows at time 0, times 1 through 10, and time 10*. It might be easier to use the tax shield approach and consider the present values of the (a) and (b) components over the projects lives. Determine the Net Present Value of the replacement proposal. Should Rogers replace the existing assembly line

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts