Question: Rogers Running seems to be operating at about 75-80% efficiency with the current product lines. They still have capacity in their schedule but will not

Rogers Running seems to be operating at about 75-80% efficiency with the current product lines. They still have capacity in their schedule but will not be able to ramp up a full production run of new shoes. With the addition of the new product, and increasing demand for the other lines due to increased marketing, Roger expects to increase sales by 30% overall.

Discuss how you will approach the capacity constraint issues, where you can make improvements to their manufacturing processes and schedules, and analyze where you foresee bottlenecks in the plant. What are your recommendations for creating a new capacity plan to meet the increasing demand and improve processes along the way?

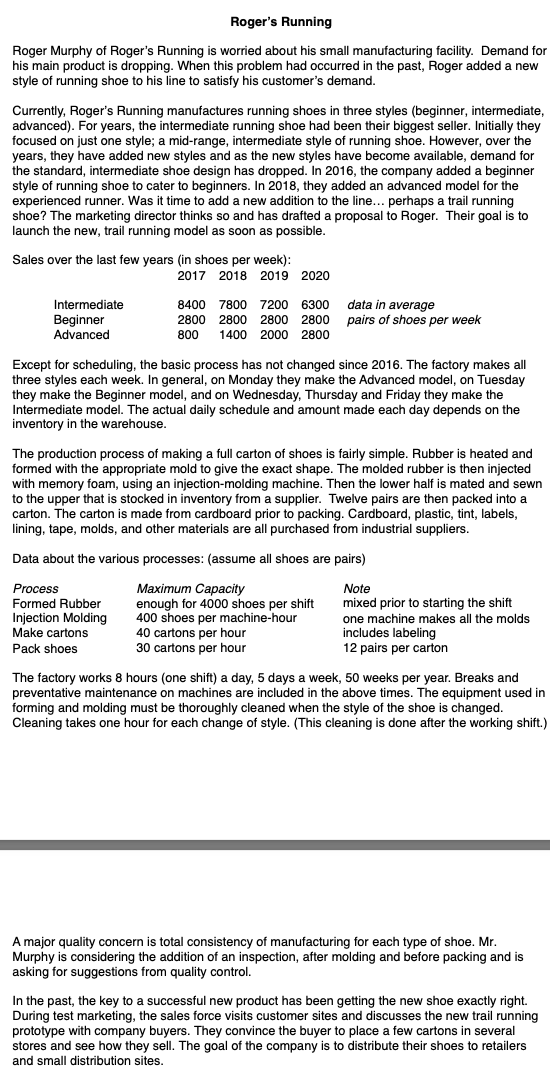

Roger's Running Roger Murphy of Roger's Running is worried about his small manufacturing facility. Demand for his main product is dropping. When this problem had occurred i the past, Roger added a new style of running shoe to his line satisfy his customer's demand. Currently, Roger's Running manufactures running shoes in three styles (beginner, intermediate, advanced). For years, the intermediate running shoe had been their biggest seller. Initially they focused on just one style; a mid-range, intermediate style of running shoe. However, over the years, they have added new styles and as the new styles have become available, demand for the standard, intermediate shoe design has dropped. In 2016, the company added a beginner style of running shoe to cater to beginners. In 2018, they added an advanced model for the experienced runner. Was it time add new addition to the line... perhaps a trail running shoe? The marketing director thinks so and has drafted a proposal to Roger. Their goal is to launch the new, trail running model as soon as possible. Sales over the last few years in shoes per week): 2017 2018 2019 2020 Intermediate Beginner Advanced 8400 7800 7200 6300 2800 2800 2800 2800 800 1400 2000 2800 data in average pairs of shoes per week Except for scheduling, the basic process has not changed since 2016. The factory makes all three styles each week. In general, on Monday they make the Advanced model, on Tuesday they make the Beginner model, and on Wednesday, Thursday and Friday they make the Intermediate model. The actual daily schedule and amount made each day depends on the inventory in the warehouse. The production process of making a full carton of shoes is fairly simple. Rubber is heated and formed with the appropriate mold to give the exact shape. The molded rubber is then injected with memory foam, using an injection-molding machine. Then the lower half is mated and sewn to the upper that is stocked in inventory from a supplier. Twelve pairs are then packed into a carton. The carton is made from cardboard prior to packing. Cardboard, plastic, tint, labels, lining, tape, molds, and other materials are all purchased from industrial suppliers. Data about the various processes: (assume all shoes are pairs) Note Process Formed Rubber Injection Molding Make cartons Pack shoes Maximum Capacity enough for 4000 shoes per shift 400 shoes per machine-hour 40 cartons per hour 30 cartons per hour mixed prior to starting the shift one machine makes all the molds includes labeling 12 pairs per carton The factory works 8 hours (one shift) a day, 5 days a week, 50 weeks per year. Breaks and preventative maintenance on machines are included in the above times. The equipment used in forming and molding must be thoroughly cleaned when the style of the shoe is changed. Cleaning takes one hour for each change of style. (This cleaning is done after the working shift.) A major quality concern is total consistency of manufacturing for each type of shoe. Mr. Murphy is considering the addition of an inspection, after molding and before packing and is asking for suggestions from quality control. a In the past, the key to a successful new product has been getting the new shoe exactly right. During test marketing, the sales force visits customer sites and discusses the new trail running prototype with company buyers. They convince the buyer to place a few cartons in several stores and see how they sell. The goal of the company is to distribute their shoes to retailers and small distribution sitesStep by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts