Question: Saint Gobain High Performance Plastics produces architectural plastics for projects such as radar domes and large pavilion - style architecture. They also produce robust industrial

Saint Gobain High Performance Plastics produces architectural plastics for projects such as radar domes and large pavilionstyle architecture. They also produce robust industrial plastics for applications such as conveyer belts in hostile environments such as extreme temperatures, extreme temperature changes or constant exposure to various kinds of radiation. Saint Gobain offers a portfolio of standard products to the marketplace to support customer projects. St Gobain products are built on a maketoorder basis with an average lead time of three weeks. Saint Gobain also has the capability to design oneoff products to customer specifications; these engineertoorder products represent a small fraction of the business less than but they are high profit margin sales. Leadtimes on ETO orders vary and can be as long as twelve weeks, depending on design complexity and engineering capacity.

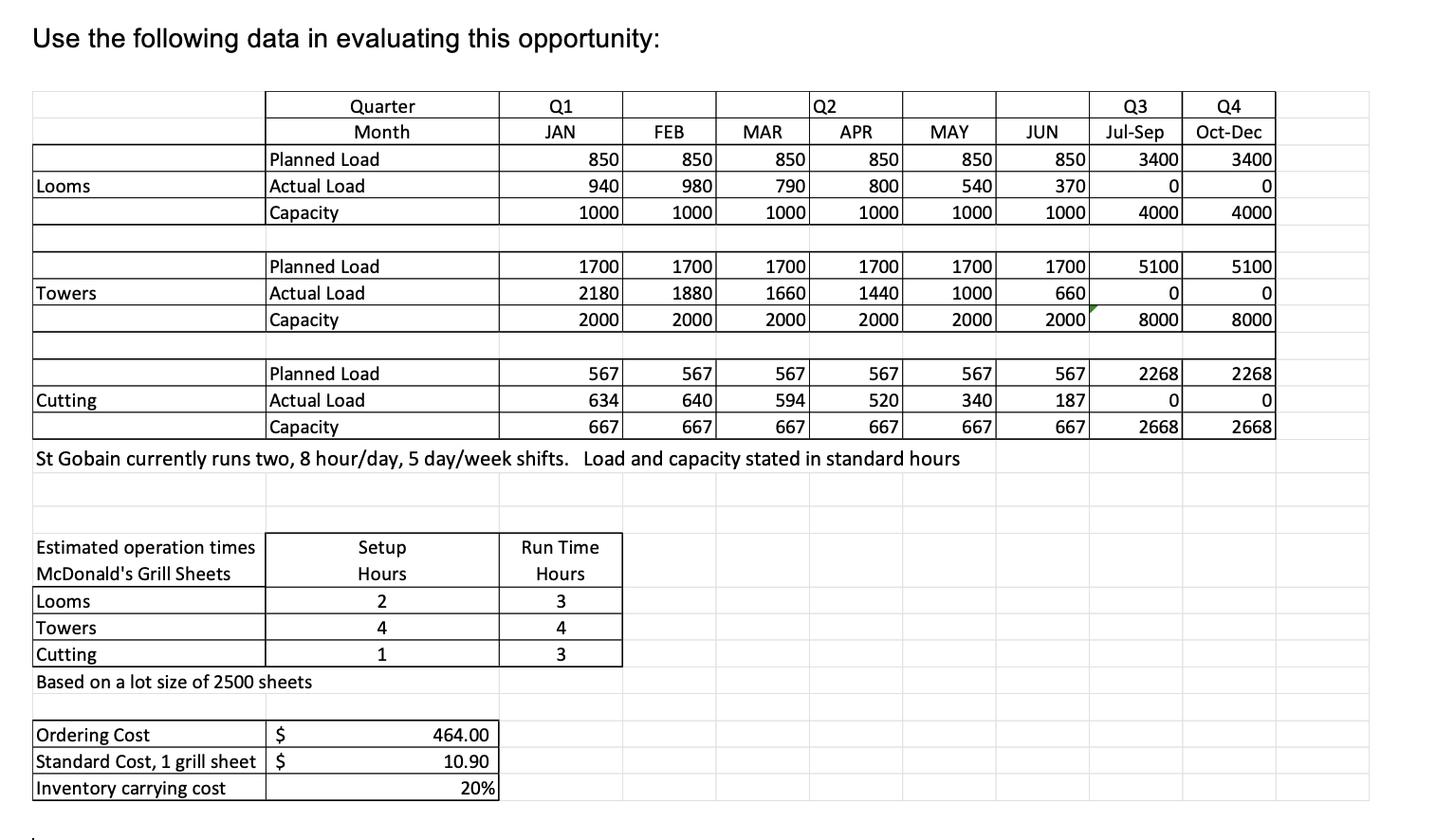

Their manufacturing process is highly capitalintensive consisting of three types of equipment:

Three industrial looms for weaving the substrate weave for their products out of various types of thread. There are a relatively small number of different substrate weave, and each form of substrate weave can be used in multiple products. Set up times and tear down for product change overs for the looms are typically in the range of two hours. Substrate is manufactured in quantities to meet the requirements of the Tower operations and is stored in rolls. The Industrial looms were purchased from a textile manufacturer that was closing and are more than eighty years old. Saint Gobain has trained technicians to maintain them.

Six Towers fivestory high, purposebuilt machines that are used to apply coatings to the substrate weave and then bake the coatings to create the plastic. The towers are enormous and occupy the majority of the floorspace in the factory. Each of the St Gobain product offerings requires a different coating. Because of the long on average four hours setup and tear down times required for product changeovers; these machines produce hundreds of yards of product per run which are stored in rolls. Each tower cost more than $M to purchase and install.

Cutting Operations: The rolls of product are cut to customer specifications which are provided at time of order. St Gobain maintains two cutting workstations. Setup times for the cutting operations are relatively short; typically, less than an hour and the run times for the cutting operation for a customer order is typically less than three hours.

Saint Gobain services all its demand by shipping from its warehouse that is colocated with the factory.

One key customer segment for Saint Gobain is the food preparation industry; they have a line of products that are FDA approved as cook safe Todate these cook safe plastics have only been marketed to industrial firms in the food processing business. Saint Gobain has a new opportunity. McDonalds has invited Saint Gobain to bid on the manufacture of the grill sheets that would be used in cooking the hamburgers in every one of the growing network of more than McDonalds restaurants worldwide. Over the last fifteen years the McDonalds network has grown by two percent per year.

Grill sheets are reusable nonstick cooking surfaces that prevent the hamburger patty from sticking to the grill during cooking. St Gobains design engineers have reviewed the specifications and are certain that one of the existing cook safe formulations can be applied with only minor changes to the Tower setup and processing. The specification calls for one grill sheet per grill and one spare grill sheet per restaurant with a useful life of at least three months in a commercial application. Most McDonalds restaurants have two grills. McDonalds has stated the requirement that a full global rollout of the grill sheets must be completed in four months after the start of the rollout. Another key requirement of the McDonalds bid would be that Saint Gobain would commit to same day pick up by McDonalds PL partners for McDonalds orders. McDonalds PL partners manage distribution to the individual restaurants in the McDonalds global network.

Estimated standard cost of one grill sheet is $; the planned bid price produces a gross profit margin which is three points lower than the industry average gross margin.

Answer all four parts to this question:

a What are your key considerations in developing a recommendation with respect to this opportunity?

b What course of action would you recommend if McDonalds requested an immediate start of the delivery process and St Gobain did not want to break any previous commitments to other customers?

Evaluate the supply chain impact of this new opportunity by identifying potential changes to the c MAKE, d DELIVER processes that would be required to execute this oppurtunity

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock