Question: Same question- asking for planned order release for A,B,C,D,E. thanks! Given the following information for the next 5 questions, including Bill of Material, develop a

Same question- asking for planned order release for A,B,C,D,E.

thanks!

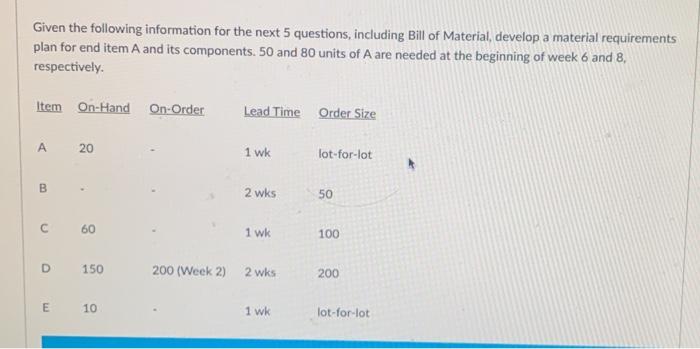

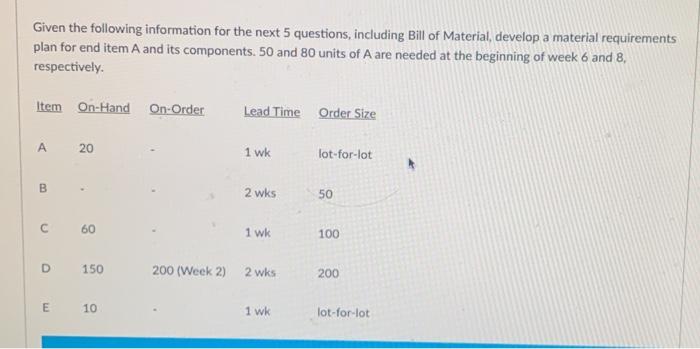

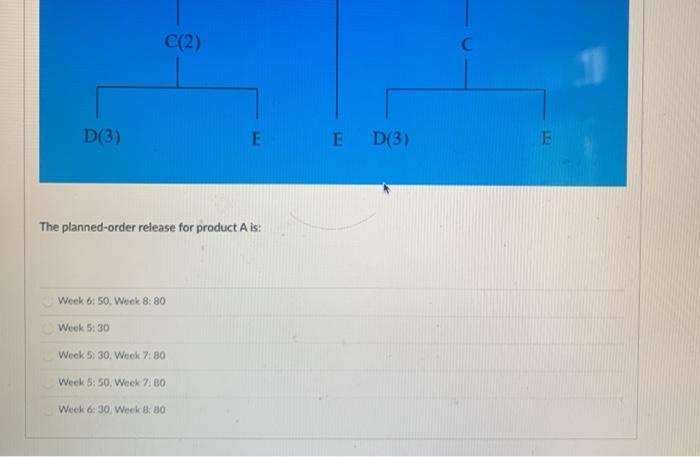

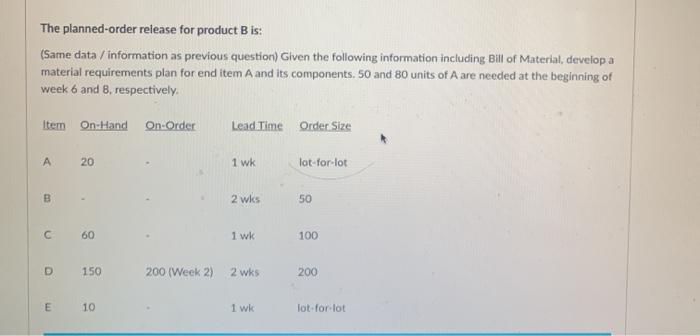

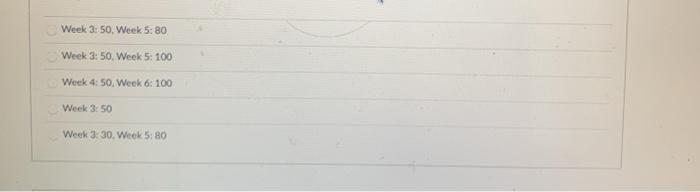

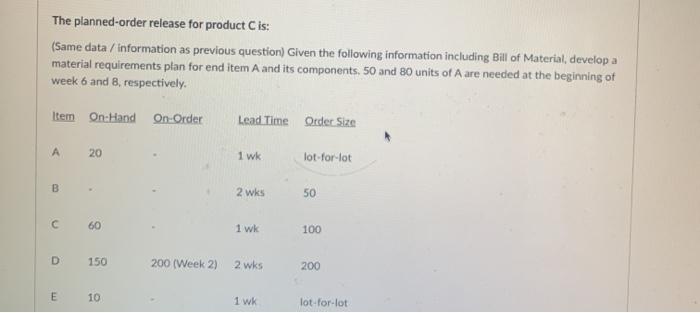

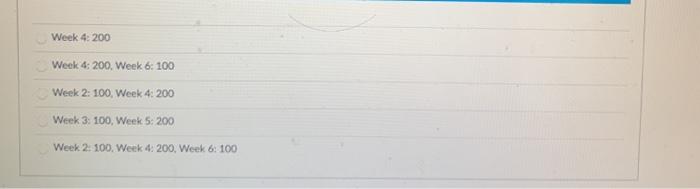

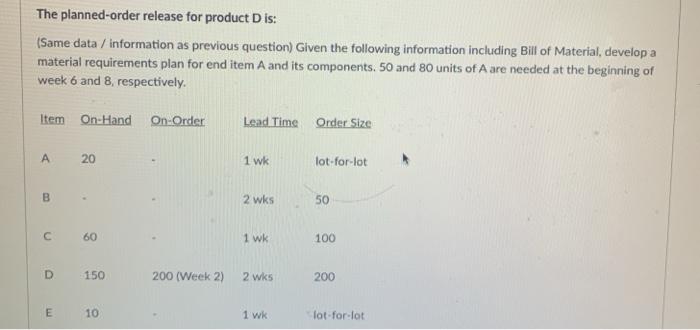

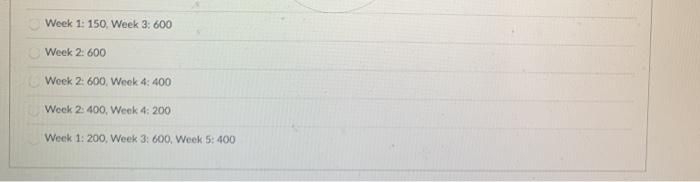

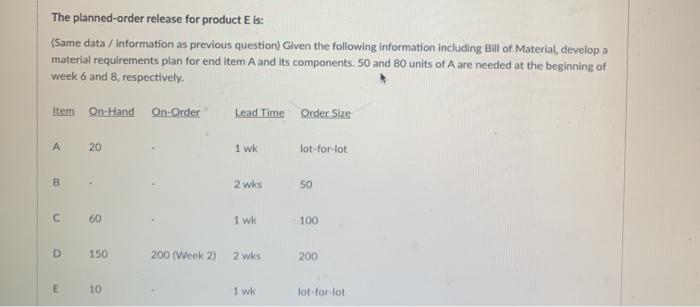

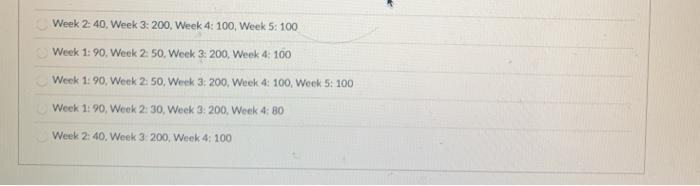

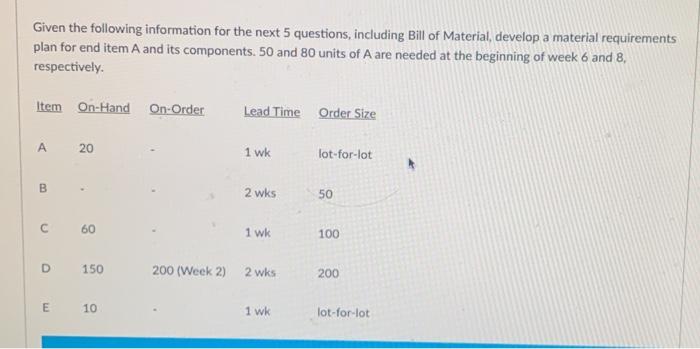

Given the following information for the next 5 questions, including Bill of Material, develop a material requirements plan for end item A and its components. 50 and 80 units of A are needed at the beginning of week 6 and 8. respectively. Item On-Hand On-Order Lead Time Order Size A 20 1 wk lot-for-lot B 2 wks 50 60 1 wk 100 D 150 200 (Week 2) 2 wks 200 E 10 1 wk lot-for-lot C(2) C D(3) EE D(3) The planned-order release for product Als: Week 6:50. Week 8.80 Week 5:30 Week 5:30. Week 7: 80 Week 5:50, Week 7:30 Week 6: 30. Weck H0 The planned-order release for product B is: (Same data/information as previous question) Given the following information including Bill of Material, develop a material requirements plan for end item A and its components. 50 and 80 units of A are needed at the beginning of week 6 and 8, respectively, Item On Hand On-Order Lead Time Order Size A 20 1 wk lot-for-lot B 2 wks 50 60 I wk 100 D 150 200 (Week 2) 2 wks 200 E 10 1 wk lot for lot Week 3:50. Week 5: 80 Week 3: 50, Week 5: 100 Week 4:50. Week 6: 100 Week 3:50 Week 3:30. Week 5: 80 The planned-order release for product Cis: (Same data / information as previous question) Given the following information including Bill of Material, develop a material requirements plan for end item A and its components. 50 and 80 units of A are needed at the beginning of week 6 and 8, respectively. Item On-Hand On-Order Lead Time Order Size 20 1 wk lot-for-lot B 2 wks 50 60 1 wk 100 D 150 200 (Week 2) 2 wks 200 E 10 1 w lot-for-lot Week 4. 200 Week 4: 200, Week 6: 100 Week 2: 100, Week 4: 200 Week 3: 100, Week 5: 200 Week 2: 100. Week 4: 200. Week 6: 100 The planned-order release for product Dis: (Same data/ information as previous question) Given the following information including Bill of Material, develop a material requirements plan for end item A and its components. 50 and 80 units of A are needed at the beginning of week 6 and 8, respectively. Item On-Hand On-Order Lead Time Order Size A 20 1 wk lot-for-lot B 2 wks 50 C 60 1 wk 100 D 150 200 (Week 2) 2 wks 200 E 10 1 wk lot for lot Week 1: 150, Week 3: 600 Week 2: 600 Week 2: 600, Week 4: 400 Week 2: 400, Week 4: 200 Week 1:200. Week 3: 600, Week 5: 400 The planned-order release for product E is: (Same data/ information as previous question) Given the following information including Bil of Material develop a material requirements plan for end item A and its components. 50 and 80 units of A are needed at the beginning of week 6 and 8, respectively. Item On-Hand On-Order Lead Time Order Size A 20 1 wk lot-for-lot B 2 wks 50 C 60 1 wk 100 D 150 200 (Week 2) 2 wks 200 E 10 1 wk lot for lot Week 2:40. Week 3: 200, Week 4: 100, Week 5: 100 Week 1: 90, Week 2:50, Week 3: 200, Week 4: 100 Week 1: 90, Week 2:50, Week 3: 200, Week 4: 100 Woek 5: 100 Week 1: 90, Week 2:30, Week 3: 200, Week 4: 80 Week 2:40. Week 3. 200, Week 4: 100