Question: SAMPLE QUESTIONS, VARIABLE DATA. ASSIGNMENT, WEEK 7 : VARIABLE DATA. Your project is running into trouble. 3 0 % of the pre - cut steel

SAMPLE QUESTIONS, VARIABLE DATA. ASSIGNMENT, WEEK : VARIABLE DATA.

Your project is running into trouble. of the precut steel girders are having to be cut

shorter on site in order to make the structure fit together. The steel supplier claims that all the

girders are within specification and that the design is not accommodating those that to the high

side of the tolerance. The engineer who designed the building says "everything would be just

fine if only the supplier could just supply material to specification. If you'd gone with the

supplier I recommended, we would never be in this fix"!

Meanwhile, your project is getting behind schedule and you have had to hire special equipment

and extra personnel to cut the inch thick girders. The standoff between the supplier and the

engineer shows no sign of resolving itself so in exasperation; you have hired an independent

engineering consultant to look at the problem. The first thing they did was to measure up of

the girders using a lasermeasuring machine. These are the results measured in inches:

What is the mean value?

What is the highest value?

What is the lowest value?

What is the range?

What is the standard deviation?

use a statistical galulator or Excel

What is the natural tolerance of the process?

The girder specification is inches plus or minus inch.

Based on the sample of measured, are there any girders out of specification?

Is the natural tolerance more or less than the specification range?

Calculate the process capability indices Cp and Cpk

std deviation

Cpk USLmean std deviations or meanLSL std deviations whichever is less.

Is the process capable?

Is the girder production process so bad that of the girders need to be cut?

Should the engineer go back to the drawing board and figure out if there is another

problem?

What would you advise the supplier?

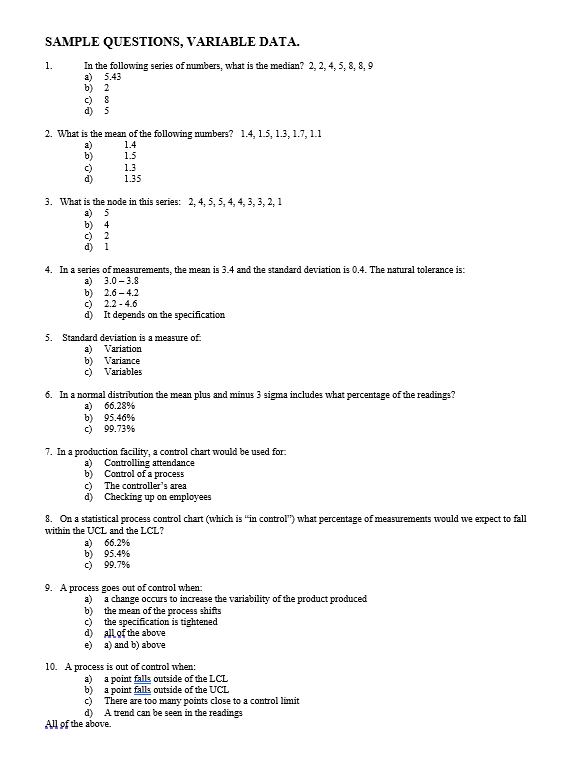

In the following series of numbers, what is the median?

a

b

c

d

What is the mean of the following numbers?

a

b

c

d

What is the node in this series:

a

b

c

d

In a series of measurements, the mean is and the standard deviation is The natural tolerance is:

a

b

c

d It depends on the specification

Standard deviation is a measure of:

a Variation

b Variance

c Variables

In a normal distribution the mean plus and minus sigma includes what percentage of the readings?

a

b

c

In a production facility, a control chart would be used for.

a Controlling attendance

b Control of a process

c The controller's area

d Checking up on employees

On a statistical process control chart which is in control" what percentage of measurements would we expect to fall

within the UCL and the LCL

a

b

c

A process goes out of control when:

a a change occurs to increase the variability of the product produced

b the mean of the process ghifts

c the specification is tightened

d all of the above

e a and b above

A process is out of control when:

a a point falls outside of the LCL

b a point falls outside of the UCL

c There are too many points close to a control limit

d A trend can be seen in the readings

All of the above.

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock