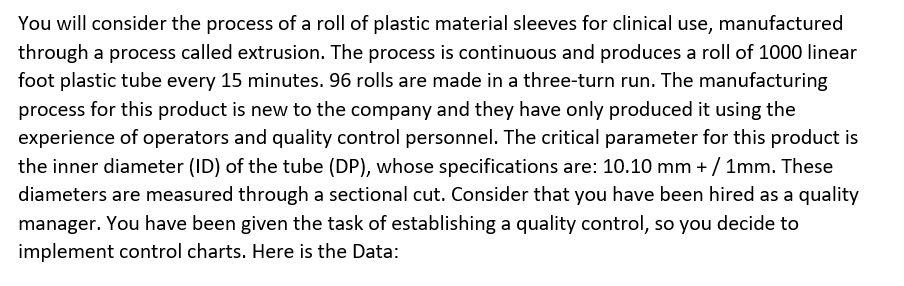

Question: Sampling Hour Shift Sample 1 Sample 2 Sample 3 Sample 4 6:00 AM 1 10.94 10.74 11.06 10.66 7:00 AM 1 10.66 10.6 10.8 10.68

| Sampling Hour | Shift | Sample 1 | Sample 2 | Sample 3 | Sample 4 |

| 6:00 AM | 1 | 10.94 | 10.74 | 11.06 | 10.66 |

| 7:00 AM | 1 | 10.66 | 10.6 | 10.8 | 10.68 |

| 8:00 AM | 1 | 10.68 | 10.6 | 10.54 | 10.36 |

| 9:00 AM | 1 | 10.03 | 10.72 | 10.74 | 10.7 |

| 10:00 AM | 1 | 10.7 | 10.62 | 11.04 | 10.58 |

| 11:00 AM | 1 | 10.38 | 10.42 | 10.66 | 10.4 |

| 12:00 PM | 1 | 10.46 | 10.6 | 10.26 | 10.02 |

| 1:00 PM | 1 | 10.66 | 10.6 | 10.22 | 10.68 |

| 2:00 PM | 2 | 10.5 | 10.78 | 10.68 | 10.58 |

| 3:00 PM | 2 | 10.58 | 10.48 | 10.58 | 10.4 |

| 4:00 PM | 2 | 10.8 | 10.74 | 10.36 | 10.6 |

| 5:00 PM | 2 | 10.42 | 10.6 | 10.64 | 10.34 |

| 6:00 PM | 2 | 10.52 | 10.6 | 10.46 | 10.6 |

| 7:00 PM | 2 | 11.04 | 10.72 | 10.56 | 10.5 |

| 8:00 PM | 2 | 10.52 | 10.62 | 10.68 | 10.7 |

| 9:00 PM | 2 | 10.38 | 10.42 | 10.76 | 10.54 |

| 10:00 PM | 3 | 10.56 | 10.6 | 10.28 | 10.68 |

| 11:00 PM | 3 | 10.58 | 10.6 | 10.58 | 10.64 |

| 12:00 AM | 3 | 10.42 | 10.78 | 10.64 | 10.86 |

| 1:00 AM | 3 | 10.01 | 10.48 | 10.84 | 10.7 |

| 2:00 AM | 3 | 10.84 | 10.64 | 10.4 | 10.52 |

| 3:00 AM | 3 | 10.54 | 10.36 | 10.6 | 11.02 |

| 4:00 AM | 3 | 10.68 | 10.4 | 10.56 | 10.32 |

| 5:00 AM | 3 | 10.7 | 10.6 | 10.74 | 10.52 |

1- Which control chart is the most appropriate to evaluate this case? Explain your answer. 2- Construct the process control graph for the critical parameter. 3- Analyze the graph and interpret your results. Determine if the process is in control or not. Explain your answer. 4- Considering the product specifications, determine the process capacity (Cpk). 5- What conclusions can you reach? What would be your next steps?

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts