Question: Scheduling A B. D E F G H I JKL MNOPQRSTU V W X Y Z AAABACADAEAFAGAFAI AJAKALANANAO AP AQ AR AS AT AU AV

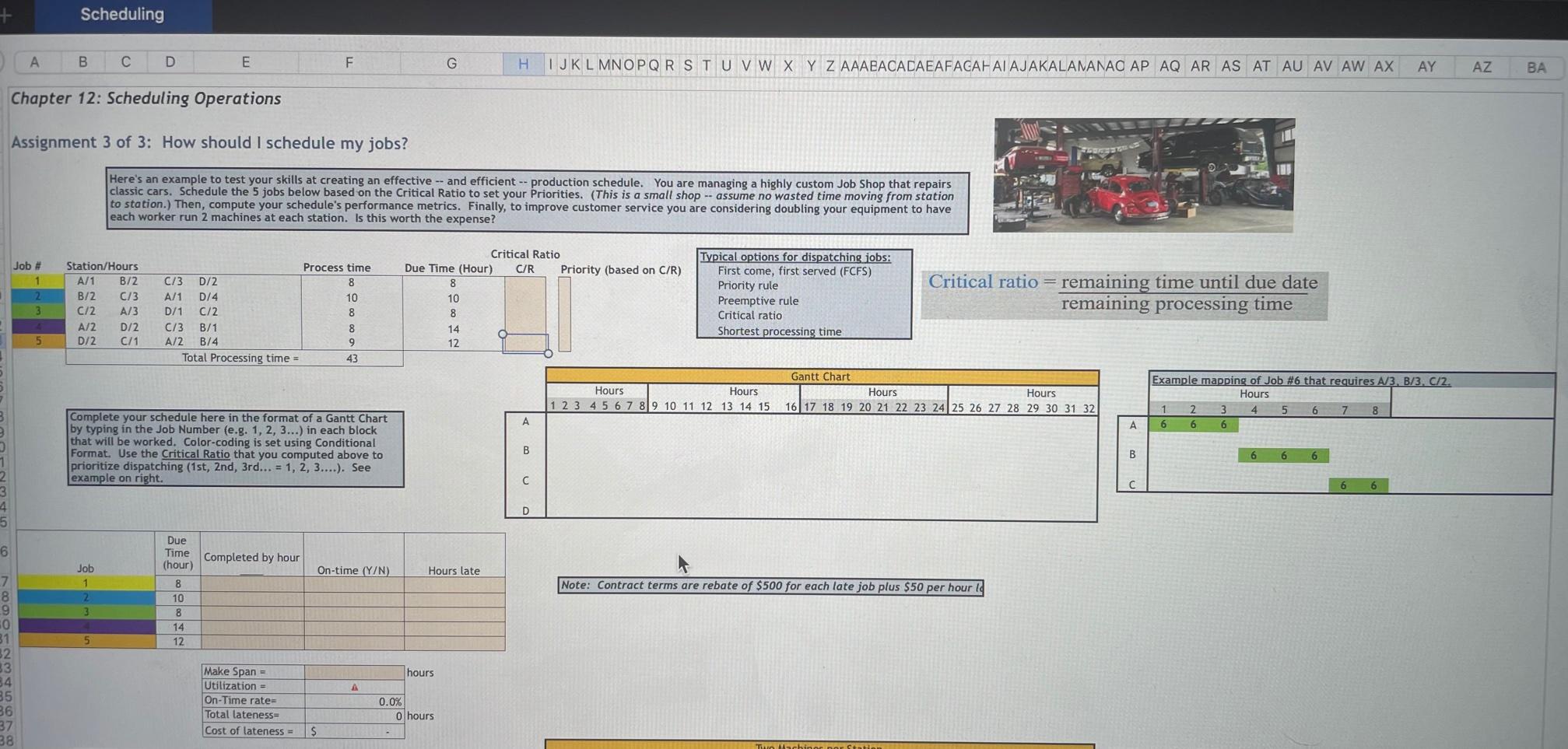

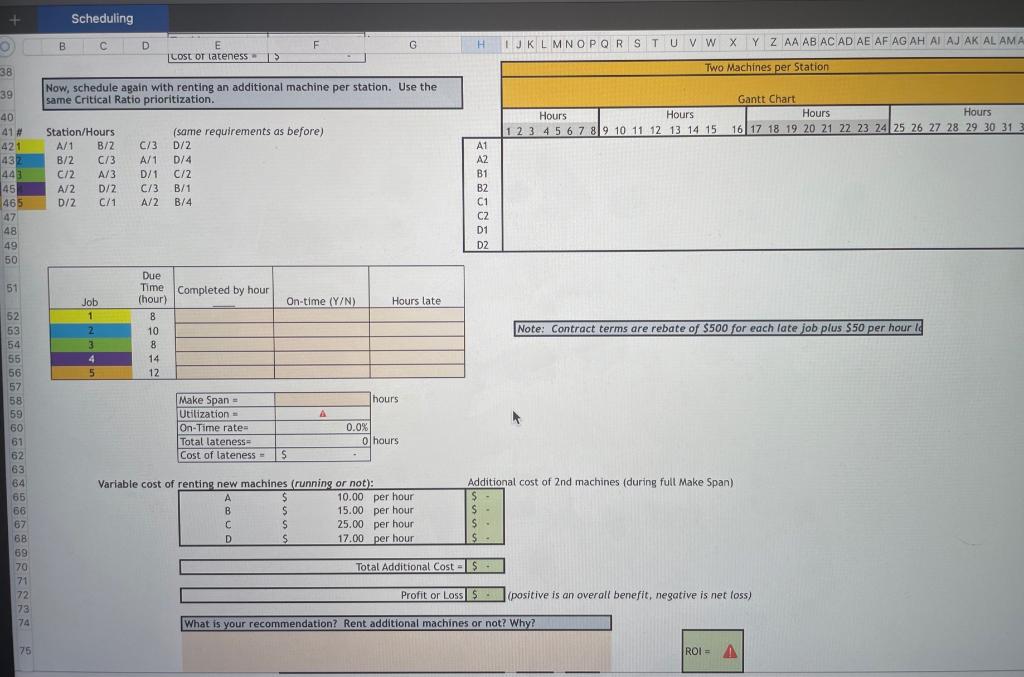

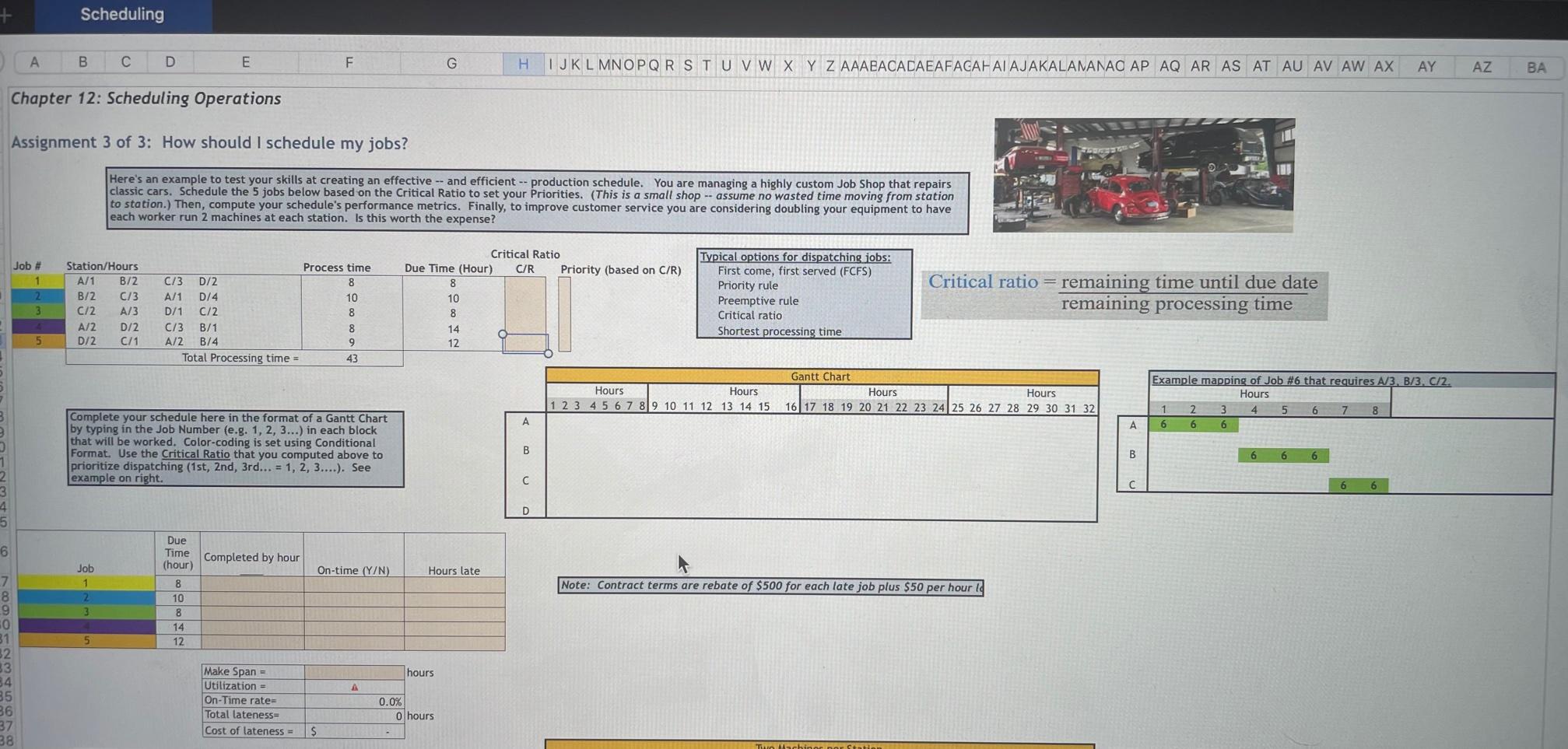

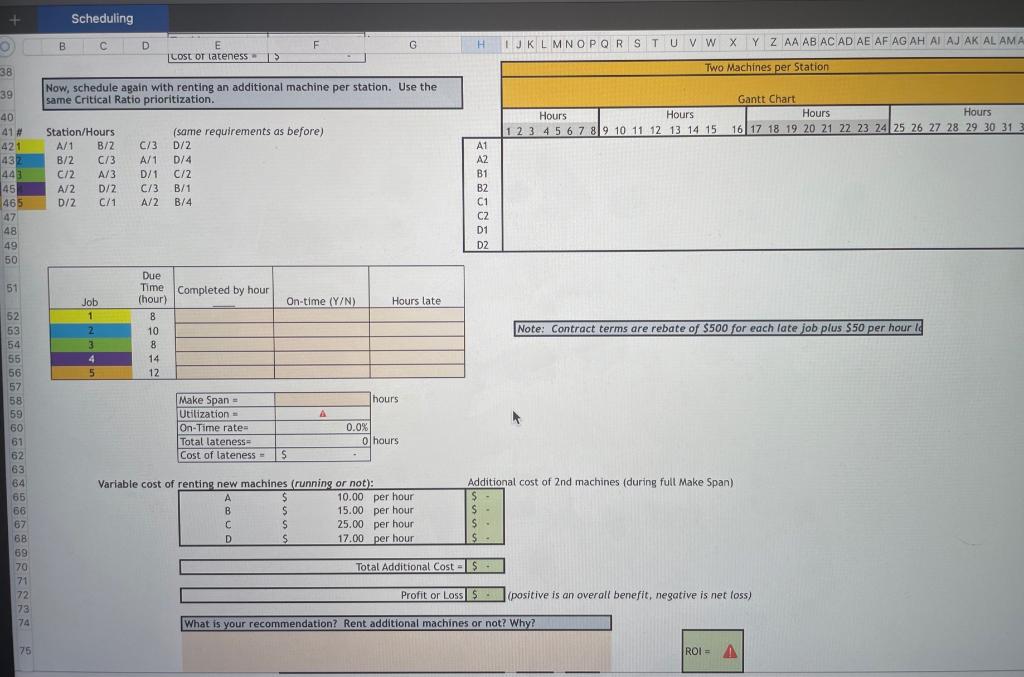

Scheduling A B. D E F G H I JKL MNOPQRSTU V W X Y Z AAABACADAEAFAGAFAI AJAKALANANAO AP AQ AR AS AT AU AV AW AX AY AZ BA Chapter 12: Scheduling Operations Assignment 3 of 3: How should I schedule my jobs? Here's an example to test your skills at creating an effective -- and efficient -- production schedule. You are managing a highly custom Job Shop that repairs classic cars. Schedule the 5 jobs below based on the Critical Ratio to set your Priorities. (This is a small shop -- assume no wasted time moving from station to station.) Then, compute your schedule's performance metrics. Finally, to improve customer service you are considering doubling your equipment to have each worker run 2 machines at each station. Is this worth the expense? Job # 1 B/2 Station/Hours A/1 B/2 C/3 C/2 A/3 A/2 D/2 D/2 C/1 Process time 8 10 8 Critical Ratio Due Time (Hour) C/R Priority (based on C/R) 8 10 8 14 12 Typical options for dispatching jobs: First come, first served (FCFS) Priority rule Preemptive rule Critical ratio Shortest processing time C/3 D/2 A/1 D/4 D/1 C/2 C/3 B/1 A/2 B/4 Total Processing time = Critical ratio = remaining time until due date remaining processing time 3 5 8 9 43 Hours Hours 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 Gantt Chart Hours Hours 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 Example mapping of Job #6 that requires A/3. B/3. C/2. Hours 1 2 4 5 6 7 8 6 6 6 A Complete your schedule here in the format of a Gantt Chart by typing in the Job Number (e.g. 1, 2, 3...) in each block that will be worked. Color-coding is set using Conditional Format. Use the Critical Ratio that you computed above to prioritize dispatching (1st, 2nd, 3rd... = 1, 2, 3 ....). See example on right. B B 6 6 6 C 6 6 D 5 6 Due Time (hour) Completed by hour Job 1 On-time (Y/N) Hours late Note: Contract terms are rebate of $500 for each late job plus $50 per hour 9 3 8 10 8 14 12 5 10 WNO hours A 34 35 36 37 38 Make Span= Utilization = On-Time rates Total lateness Cost of lateness - 0.0% 0 hours $ This marca + Scheduling O B C D F G H E Cost of lateness LJKLMNOPQRSTU V W X V W Y Z AA AB AC AD AE AF AG AH AI AJ AK AL AMA T> 38 Two Machines per Station 39 Now, schedule again with renting an additional machine per station. Use the same Critical Ratio prioritization. 40 Hours Hours 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 Gantt Chart Hours Hours 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 421 432 443 45 465 47 48 49 50 Station/Hours A/1 B/2 B/2 C/3 C/2 A/3 A/2 D/2 D/2 C/1 C/3 A/1 D/1 C/3 A/2 (same requirements as before) D/2 D/4 C/2 B/1 B/4 A1 A2 B1 B2 C1 CZ D1 D2 51 On-time (Y/N) Hours late Due Time Completed by hour (hour) B 10 8 8 14 12 Job 1 2 3 4 5 Note: Contract terms are rebate of $500 for each late job plus S50 per hour hours Make Span Utilization On-Time rate Total lateness Cost of lateness 0.0% 0 hours S 52 59 54 55 56 57 58 59 60 61 62 63 64 65 66 67 68 69 70 71 72 73 74 Additional cost of 2nd machines (during full Make Span) Variable cost of renting new machines (running or not): A $ 10.00 per hour B S 15.00 per hour $ 25.00 per hour D $ 17.00 per hour Total Additional Cost = $. Profit or Loss Spositive is an overall benefit, negative is net loss) What is your recommendation? Rent additional machines or not? Why? 75 ROI = 1 Scheduling A B. D E F G H I JKL MNOPQRSTU V W X Y Z AAABACADAEAFAGAFAI AJAKALANANAO AP AQ AR AS AT AU AV AW AX AY AZ BA Chapter 12: Scheduling Operations Assignment 3 of 3: How should I schedule my jobs? Here's an example to test your skills at creating an effective -- and efficient -- production schedule. You are managing a highly custom Job Shop that repairs classic cars. Schedule the 5 jobs below based on the Critical Ratio to set your Priorities. (This is a small shop -- assume no wasted time moving from station to station.) Then, compute your schedule's performance metrics. Finally, to improve customer service you are considering doubling your equipment to have each worker run 2 machines at each station. Is this worth the expense? Job # 1 B/2 Station/Hours A/1 B/2 C/3 C/2 A/3 A/2 D/2 D/2 C/1 Process time 8 10 8 Critical Ratio Due Time (Hour) C/R Priority (based on C/R) 8 10 8 14 12 Typical options for dispatching jobs: First come, first served (FCFS) Priority rule Preemptive rule Critical ratio Shortest processing time C/3 D/2 A/1 D/4 D/1 C/2 C/3 B/1 A/2 B/4 Total Processing time = Critical ratio = remaining time until due date remaining processing time 3 5 8 9 43 Hours Hours 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 Gantt Chart Hours Hours 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 Example mapping of Job #6 that requires A/3. B/3. C/2. Hours 1 2 4 5 6 7 8 6 6 6 A Complete your schedule here in the format of a Gantt Chart by typing in the Job Number (e.g. 1, 2, 3...) in each block that will be worked. Color-coding is set using Conditional Format. Use the Critical Ratio that you computed above to prioritize dispatching (1st, 2nd, 3rd... = 1, 2, 3 ....). See example on right. B B 6 6 6 C 6 6 D 5 6 Due Time (hour) Completed by hour Job 1 On-time (Y/N) Hours late Note: Contract terms are rebate of $500 for each late job plus $50 per hour 9 3 8 10 8 14 12 5 10 WNO hours A 34 35 36 37 38 Make Span= Utilization = On-Time rates Total lateness Cost of lateness - 0.0% 0 hours $ This marca + Scheduling O B C D F G H E Cost of lateness LJKLMNOPQRSTU V W X V W Y Z AA AB AC AD AE AF AG AH AI AJ AK AL AMA T> 38 Two Machines per Station 39 Now, schedule again with renting an additional machine per station. Use the same Critical Ratio prioritization. 40 Hours Hours 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 Gantt Chart Hours Hours 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 421 432 443 45 465 47 48 49 50 Station/Hours A/1 B/2 B/2 C/3 C/2 A/3 A/2 D/2 D/2 C/1 C/3 A/1 D/1 C/3 A/2 (same requirements as before) D/2 D/4 C/2 B/1 B/4 A1 A2 B1 B2 C1 CZ D1 D2 51 On-time (Y/N) Hours late Due Time Completed by hour (hour) B 10 8 8 14 12 Job 1 2 3 4 5 Note: Contract terms are rebate of $500 for each late job plus S50 per hour hours Make Span Utilization On-Time rate Total lateness Cost of lateness 0.0% 0 hours S 52 59 54 55 56 57 58 59 60 61 62 63 64 65 66 67 68 69 70 71 72 73 74 Additional cost of 2nd machines (during full Make Span) Variable cost of renting new machines (running or not): A $ 10.00 per hour B S 15.00 per hour $ 25.00 per hour D $ 17.00 per hour Total Additional Cost = $. Profit or Loss Spositive is an overall benefit, negative is net loss) What is your recommendation? Rent additional machines or not? Why? 75 ROI = 1