Question: Scotsburn Dairy: The MPS Problem The master scheduling problem at Scotsburn is to determine the production quantity for the products during each week for the

Scotsburn Dairy: The MPS Problem

The master scheduling problem at Scotsburn is to determine the production quantity for

the products during each week for the next weeks subject to the limitation of

production hours imposed by the aggregate production plan. Because some products

have "joint" setup, it is more efficient to group them as a family if possible. For example,

some products are made from the same base mix eg no sugar and some use the

same tub size eg two litres Changing base mix on a line requires washing all the

equipment, and changing the tub size requires physical adjustment to the filling and

packaging equipment. Either action requires approximately a halfhour, and changing

base mix also results in approximately $ of wasted mix. Exceptions include

multiflavour products eg Neapolitan ice cream which require tight coordination of

flavours, and products containing a particular allergen eg peanuts In these cases,

all sizes of these products should be included in their own family. Within a family, a

flavour or fruit change requires approximately five minutes.

Sccotsburn produces tens of families of ice cream and frozen yogurt on three lines. For

simplicity, we assume two families, one line, and only three weeks. Suppose that the

setup time for each family is one hour, cost of labour involved in changeover is $ per

hour, and cost of mix loss is $ Holding cost rate is percent per year, cost of one

litre of ice cream is $ and there are workweeks per year.

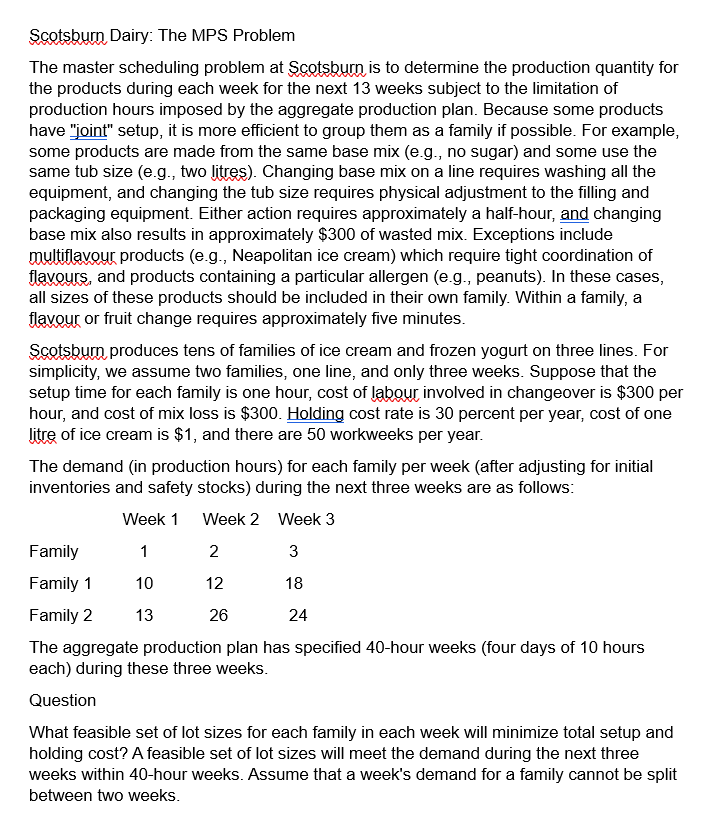

The demand in production hours for each family per week after adjusting for initial

inventories and safety stocks during the next three weeks are as follows:

The aggregate production plan has specified hour weeks four days of hours

each during these three weeks.

Question

What feasible set of lot sizes for each family in each week will minimize total setup and

holding cost? A feasible set of lot sizes will meet the demand during the next three

weeks within hour weeks. Assume that a week's demand for a family cannot be split

between two weeks.

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock