Question: See below... Answer to Question 6 is needed ONLY. QUESTION 6: Further to the data provided above for 3 estimates, the management is now contemplating

See below... Answer to Question 6 is needed ONLY.

QUESTION 6: Further to the data provided above for 3 estimates, the management is now contemplating to crash the network to the minimum possible time under the crash cost schedule as follows:

1. Activity A can be crashed at most by 1 week with a cost increase of $5,000 per week 2. activity B can be crashed at most by 2 weeks increase with a cost increase of $4,000 per week 3. activity C can be crashed at most by 0.5 week with a cost increase of $8,000 per week 4. Activity D can be crashed at most by 3 weeks with a cost increase of $5,000 per week 5. Activity E can be crashed at most by 1 week with a cost increase of $6,000 per week 6. Activity F can be crashed at most by 2 weeks with a cost increase of $4,000 per week 7. Activity G can be crashed at most by 1 week with a cost increase of $3,000 per week.

A. Formulate the problem as a linear programming probem with the objective of minimizing the total crashing cost with the stipulation of completing the project in ten weeks. B. Solve the formulation above by QM for Windows to obtain the optimal answer. You must submit the original computer output to get credit for this part.

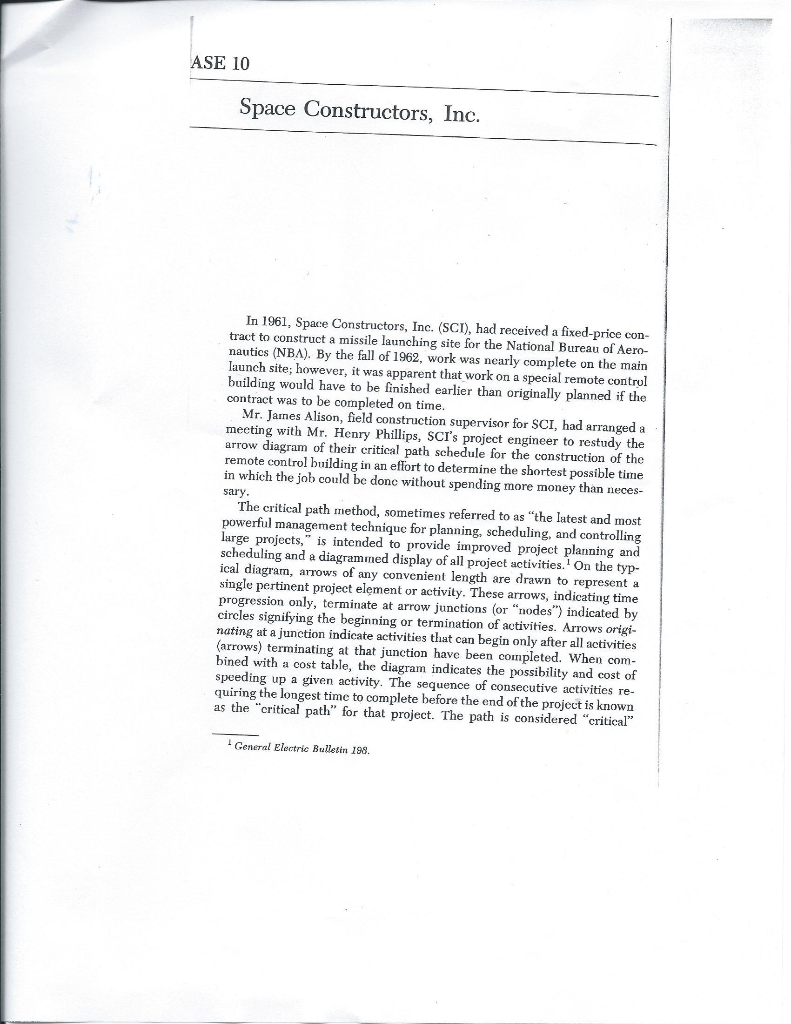

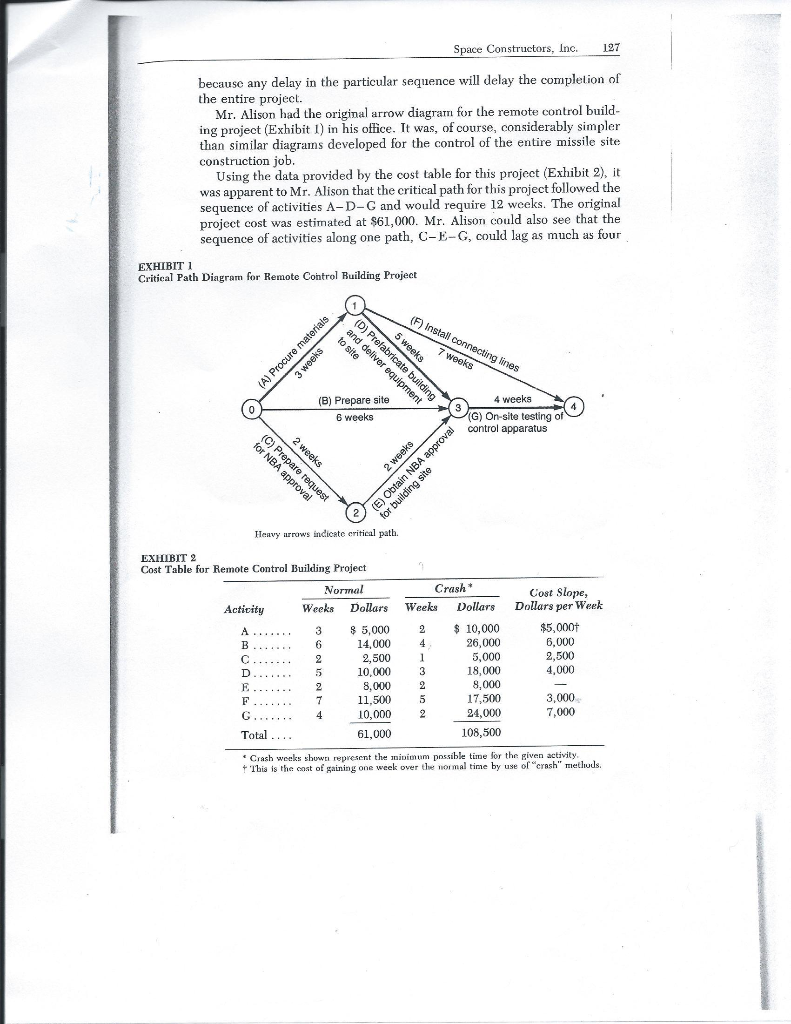

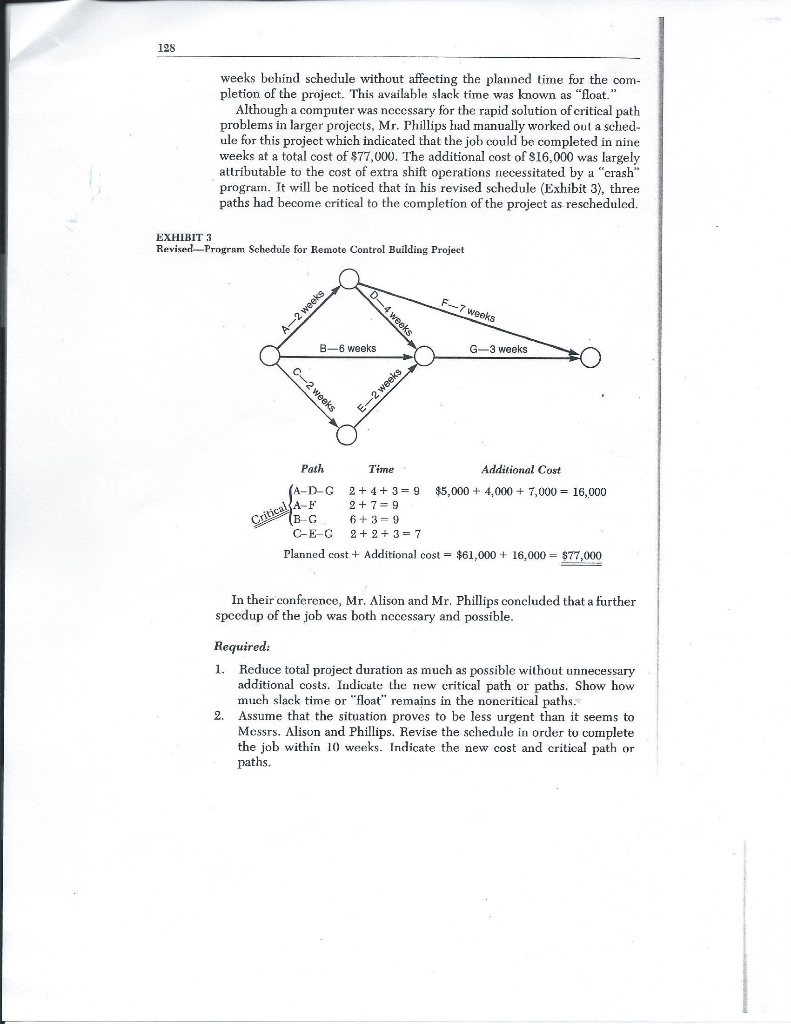

ASE 10 Space Constructors, Inc. sary, In 1961, Space Constructors, Inc. (SCI), had received a fixed-price con- tract to construct a missile launching site for the National Bureau of Aero- nautics (NBA). By the fall of 1962, work was nearly complete on the main launch site; however, it was apparent that work on a special remote control building would have to be finished earlier than originally planned if the contract was to be completed on time. Mr. James Alison, field construction supervisor for SCI, had arranged a meeting with Mr. Henry Phillips, SCI's project engineer to restudy the arrow diagram of their critical path schedule for the construction of the remote control building in an effort to determine the shortest possible time in which the job could be done without spending more money than neces- The critical path method, sometimes referred to as "the latest and most powerful management technique for planning, scheduling, and controlling large projects," is intended to provide improved project planning and scheduling and a diagrammed display of all project activities. On the typ- ical diagram, arrows of any convenient length are drawn to represent a single pertinent project element or activity. These arrows, indicating time circles signifying the beginning or termination of activities. Arrows origi- progression only, terminate at arrow junctions (or "nodes") indicated by nating at a junction indicate activities that can begin only after all activities (arrows) terminating at that junction have been completed. When com- bined with a cost table, the diagram indicates the possibility and cost of speeding up a given activity. The sequence of consecutive activities re- quiring the longest time to complete before the end of the project is known as the "critical path" for that project. The path is considered "critical" General Electric Bulletin 198. Space Constructors, Inc. 127 because any delay in the particular sequence will delay the completion of the entire project. Mr. Alison had the original arrow diagram for the remote control build- ing project (Exhibit 1) in his office. It was, of course, considerably simpler than similar diagrams developed for the control of the entire missile site construction job. Using the data provided by the cost table for this project (Exhibit 2), it was apparent to Mr. Alison that the critical path for this project followed the sequence of activities A-D-G and would require 12 weeks. The original project cost was estimated at $61,000. Mr. Alison could also see that the sequence of activities along one path, C-E-G, could lag as much as four EXHIBIT 1 Critical Path Diagram for Remote Control Building Project 5 weeks (D) Prefabricate building and deliver equipment to site (F) Install connecting lines 7 weeks (A) Procure materials 3 weeks (B) Prepare site 6 weeks 4 weeks 3 (G) On-site testing of control apparatus 2 weeks for NBA approval (C) Prepare request 2 weeks (E) Obtain NBA approval for building site Heavy arrows indicate critical path. EXHIBIT 2 Cost Table for Remote Control Building Project Normal Weeks Dollars Activity Cost Slope, , Dollars per week $5,000+ 6.000 2,500 A B D....... E... F 3 6 2 5 2 7 4 Crash Weeks Dollars $ 10,000 4 26,000 1 5,000 3 18,000 2 8,000 5 17,500 2 24,000 108,500 8 5,000 14,000 2,500 10,000 8,000 11,500 10,000 61,000 4,000 3,000 7,000 Total .... * Crash wenks showti represent the minimum possible time for the given activity + This is the cost of gaining one week over the normal time by use of crash" methods 128 weeks behind schedule without affecting the planned time for the com- pletion of the project. This available slack time was known as "float." Although a computer was necessary for the rapid solution of critical path problems in larger projects, Mr. Phillips had manually worked out a sched- ule for this project which indicated that the job could be completed in nine weeks at a total cost of $77,000. The additional cost of 816,000 was largely attributable to the cost of extra shift operations necessitated by a "crash" program. It will be noticed that in his revised schedule (Exhibit 3), three paths had become critical to the completion of the project as rescheduled. EXHIBIT 3 Revised.--- Program Schedule for Remote Control Building Project F7 weeks A-2 weeks D-4 weeks B-6 weeks G-3 weeks C-2 weeks E-2 weeks Critical Path Time Additional Cost (A-D-G 2 + 4 + 3 = 9 $5,000 + 4,000 + 7,000 = 16,000 2 + 7 = 9 (B-G 6 +3= 9 C-E-C 2+ 2 + 3 = 7 Planned cost + Additional cost = $61,000+ 16,000 = $77,000 In their conference, Mr. Alison and Mr. Phillips concluded that a further speedup of the job was both necessary and possible. Required: 1. Reduce total project duration as much as possible without unnecessary additional costs. Indicate the new critical path or paths. Show how much slack time or "float" remains in the noncritical paths. 2. Assume that the situation proves to be less urgent than it seems to Messrs. Alison and Phillips. Revise the schedule in order to complete the job within 10 weeks. Indicate the new cost and critical path or paths

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts