Question: Select yes or no a. Whether and how fast to boost production capabilities for the Model 3. (Click to select) Yes No b. How much

Select yes or no

a. Whether and how fast to boost production capabilities for the Model 3.

(Click to select) Yes No

b. How much to spend currently on R&D for the Tesla Semi and the Model Y? Does the planned development, production, and introduction of these models need to be delayed by several months in order to conserve on near-term capital requirements, postpone further issues of debt or equity, focus most all resources on production and sale of models S, X, and E, and prove the companys profitability?

(Click to select) Yes No

c. Will the demand for Tesla electric vehicles in China prove to be strong and sustainable?

(Click to select) Yes No

d. How fast to proceed with construction of a production plant in China? Is more time needed to evaluate/determine the companys ability to finance the construction of this plant and install the needed production equipment?

(Click to select) Yes No

e. How fast to expand the network of recharging stations in the United States, Western Europe, and China?

(Click to select) Yes No

f. What happens to buyer demand for electric-powered vehicles if gasoline prices stay below $3.00 per gallon and expectations become widespread that they might remain there for several years or even much longer?

(Click to select) Yes No

g. Whether to continue expansion of their Gigafactory in order to increase production.

(Click to select) Yes No

h. As Tesla begins to sell more and more vehicles annually in the United States, will traditional automobile dealers start to clamor loudly for strict enforcement of state laws prohibiting automobile manufacturers from selling direct to motor vehicle buyers.

(Click to select) Yes No

i. Whether to increase R&D spending to stay ahead of the competition.

(Click to select) Yes No

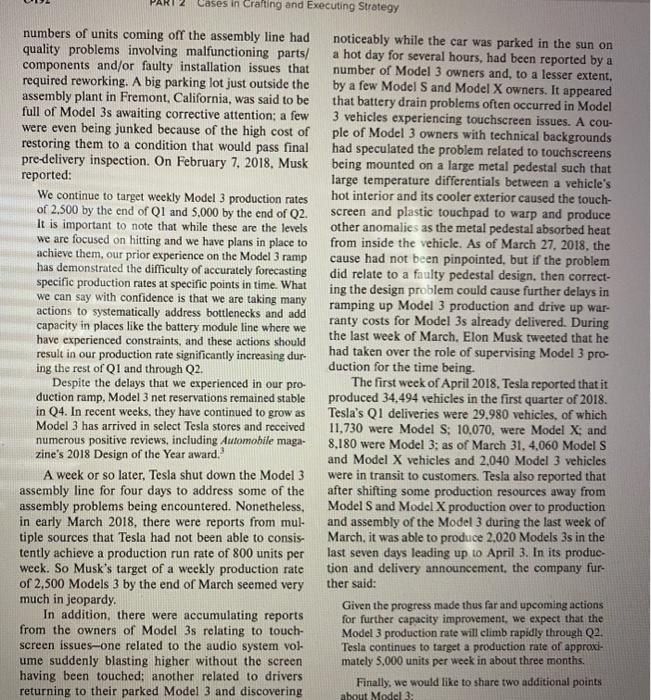

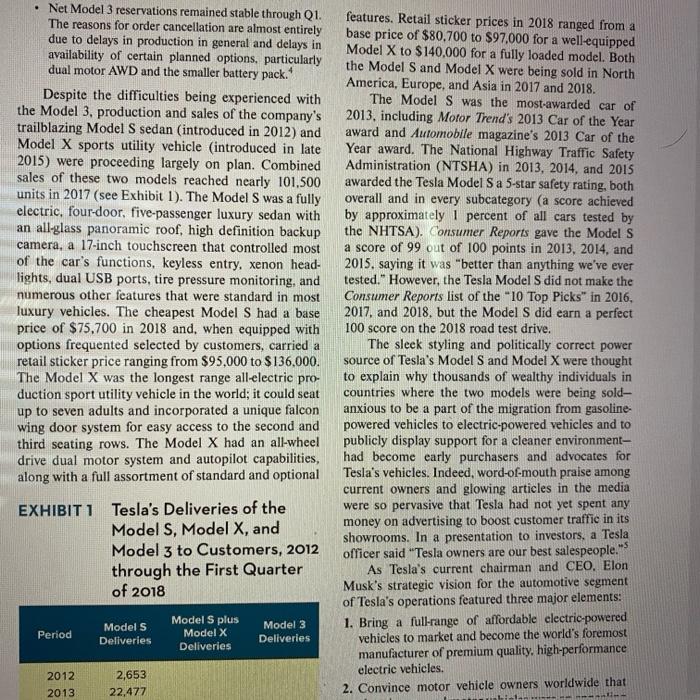

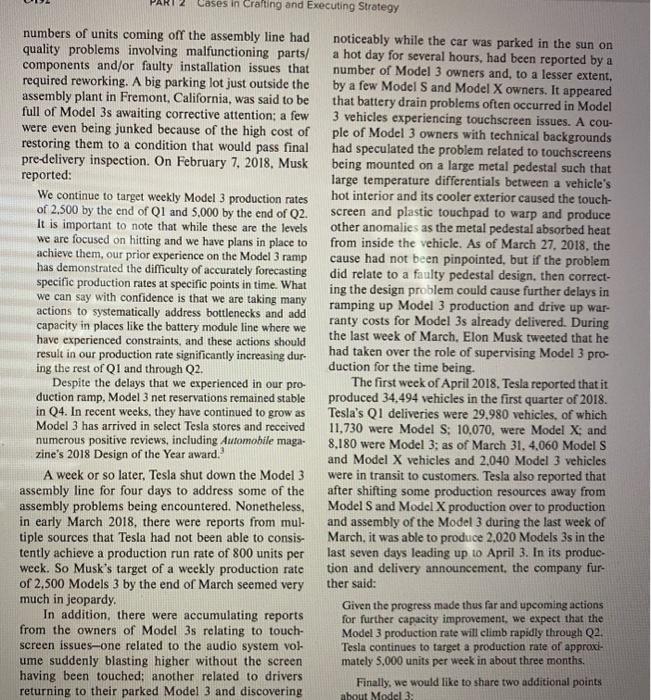

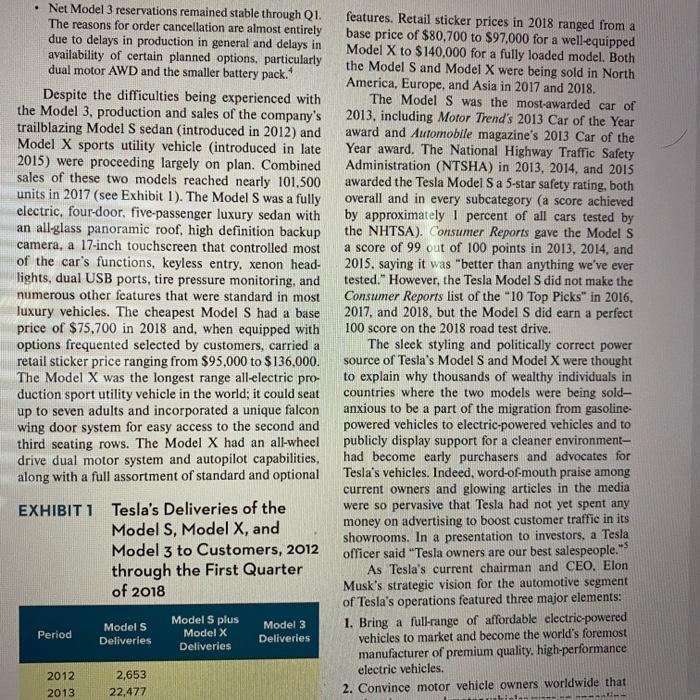

Arthur A. Thompson The University of Alabama esla Motors began assembling the first mod- els of its new affordably-priced" entry-level Model 3 electric car in May 2017 and delivered the first units the last week of July, with a goal of gradually ramping up production to a total of 1.500 units by the end of September. The first production vehicles, delivered to employees who had placed pre- production reservations over a year earlier, were pre- configured with rear-wheel drive and a long-range battery: had a range of 310 miles and 0 to 60 mph acceleration time of 5.1 seconds; and a sticker price starting at $44,000 with premium upgrades available for an additional $5.000. Deliveries of the standard Model 3, with a base price of $35.000. 220 miles of range, and a 0 to 60 mph acceleration time of 5.6 sec. onds, were expected to begin in the United States in November 2017. Dual motor all-wheel drive configu- rations were scheduled to be available in early 2018. Plans called for international deliveries of the Model 3 to begin in late 2018, contingent upon regulatory approvals, starting with left-hand drive markets and followed by right-hand drive markets in 2019. Tesla had unveiled six drivable prototypes of the Model 3 for public viewing and a limited number of test drives on the evening of March 31, 2016. Buyer reaction was overwhelmingly positive. Over the next two weeks, some 350.000 individuals paid a $1,000 deposit to reserve a place in line to obtain a Model 3: reportedly, the number of reservations grew to nearly 400,000 units over the next several months. Because of the tremendous amount of interest in the Model 3. Tesla Chairman and CEO Elon Musk announced in May 2016 that Tesla was advancing its schedule to begin producing the Model 3 from late 2017 to mid- 2017 and further that it was going to accelerate its efforts to expand production capacity of the Model 3, with a goal of getting to a production run rate of 500,000 units annually by year-end 2018 instead of year-end 2020. In early August 2017, in a letter updating share- holders on the company's second quarter 2017 results, Musk said: Based on our preparedness at this time, we are confi- dent we can produce just over 1,500 [ Model 31 vehicles in Q3 and achieve a run rate of 5.000 vehicles per week by the end of 2017. We also continue to plan on increas- ing Model 3 production to 10,000 vehicles per week at some point in 2018. But in his third quarter 2017 update on November 1, 2017, Musk related a host of produc- tion bottlenecks and challenges that were blocking the ramp-up of Model 3 production and delaying deliveries, saying, "this makes it difficult to predict exactly how long it will take for all bottlenecks to be cleared or when new ones will appear. Based on what we know now, we currently expect to achieve a pro- duction rate of 5,000 Model 3 vehicles per week by late Q1 2018.02 But Tesla's "production hell" with the Model 3 continued to haunt the company in early 2018. Many analysts believed Tesla's problems stemmed from having taken huge shortcuts in the parts approval process, production line validation, and full beta test- ing of the Model 3 in order to begin early assembly and production ramp-up. There were other reasons, including ongoing parts bottlenecks and inconsis- tent manufacturing quality. Production line employ- ees interviewed by reporters indicated significant Copyright 2019 by Arthur A. Thompson. All rights reserved. Cases in Crafting and Executing Strategy numbers of units coming off the assembly line had quality problems involving malfunctioning parts/ components and/or faulty installation issues that required reworking. A big parking lot just outside the assembly plant in Fremont, California, was said to be full of Model 3s awaiting corrective attention: a few were even being junked because of the high cost of restoring them to a condition that would pass final predelivery inspection. On February 7, 2018, Musk reported: We continue to target weekly Model 3 production rates of 2.500 by the end of Q1 and 5,000 by the end of Q2. It is important to note that while these are the levels we are focused on hitting and we have plans in place to achieve them, our prior experience on the Model 3 ramp has demonstrated the difficulty of accurately forecasting specific production rates at specific points in time. What we can say with confidence is that we are taking many actions to systematically address bottlenecks and add capacity in places like the battery module line where we have experienced constraints, and these actions should result in our production rate significantly increasing dur- ing the rest of Q1 and through Q2. Despite the delays that we experienced in our pro- duction ramp, Model 3 net reservations remained stable in Q4. In recent weeks, they have continued to grow as Model 3 has arrived in select Tesla stores and received numerous positive reviews, including Automobile maga- zine's 2018 Design of the Year award. A week or so later, Tesla shut down the Model 3 assembly line for four days to address some of the assembly problems being encountered. Nonetheless, in early March 2018, there were reports from mul- tiple sources that Tesla had not been able to consis tently achieve a production run rate of 800 units per week. So Musk's target of a weekly production rate of 2.500 Models 3 by the end of March seemed very much in jeopardy. In addition, there were accumulating reports from the owners of Model 3s relating to touch- screen issues-one related to the audio system vol- ume suddenly blasting higher without the screen having been touched: another related to drivers returning to their parked Model 3 and discovering noticeably while the car was parked in the sun on a hot day for several hours, had been reported by a number of Model 3 owners and, to a lesser extent, by a few Model S and Model X owners. It appeared that battery drain problems often occurred in Model 3 vehicles experiencing touchscreen issues. A cou- ple of Model 3 owners with technical backgrounds had speculated the problem related to touchscreens being mounted on a large metal pedestal such that large temperature differentials between a vehicle's hot interior and its cooler exterior caused the touch- screen and plastic touchpad to warp and produce other anomalies as the metal pedestal absorbed heat from inside the vehicle. As of March 27, 2018, the cause had not been pinpointed, but if the problem did relate to a faulty pedestal design, then correct- ing the design problem could cause further delays in ramping up Model 3 production and drive up war- ranty costs for Model 3s already delivered. During the last week of March, Elon Musk tweeted that he had taken over the role of supervising Model 3 pro- duction for the time being. The first week of April 2018. Tesla reported that it produced 34,494 vehicles in the first quarter of 2018. Tesla's QI deliveries were 29,980 vehicles, of which 11,730 were Model S: 10.070, were Model X; and 8.180 were Model 3: as of March 31. 4.060 Model S and Model X vehicles and 2.040 Model 3 vehicles were in transit to customers. Tesla also reported that after shifting some production resources away from Model S and Model X production over to production and assembly of the Model 3 during the last week of March, it was able to produce 2.020 Models 3s in the last seven days leading up to April 3. In its produc- tion and delivery announcement, the company fur- ther said: Given the progress made thus far and upcoming actions for further capacity improvement, we expect that the Model 3 production rate will climb rapidly through Q2. Tesla continues to target a production rate of approxi- mately 5,000 units per week in about three months. Finally, we would like to share two additional points about Model 3: Net Model 3 reservations remained stable through Q1. The reasons for order cancellation are almost entirely due to delays in production in general and delays in availability of certain planned options, particularly dual motor AWD and the smaller battery pack.* Despite the difficulties being experienced with the Model 3, production and sales of the company's trailblazing Model S sedan (introduced in 2012) and Model X sports utility vehicle (introduced in late 2015) were proceeding largely on plan. Combined sales of these two models reached nearly 101,500 units in 2017 (see Exhibit 1). The Model S was a fully electric, four-door, five-passenger luxury sedan with an all-glass panoramic roof, high definition backup camera, a 17-inch touchscreen that controlled most of the car's functions, keyless entry. xenon head- lights, dual USB ports, tire pressure monitoring, and numerous other features that were standard in most luxury vehicles. The cheapest Model S had a base price of $75,700 in 2018 and, when equipped with options frequented selected by customers, carried a retail sticker price ranging from $95,000 to $136.000. The Model X was the longest range all-electric pro- duction sport utility vehicle in the world; it could seat up to seven adults and incorporated a unique falcon wing door system for easy access to the second and third seating rows. The Model X had an all-wheel drive dual motor system and autopilot capabilities, along with a full assortment of standard and optional features. Retail sticker prices in 2018 ranged from a base price of $80,700 to $97,000 for a well-equipped Model X to $140,000 for a fully loaded model. Both the Model S and Model X were being sold in North America, Europe, and Asia in 2017 and 2018. The Model S was the most-awarded car of 2013, including Motor Trend's 2013 Car of the Year award and Automobile magazine's 2013 Car of the Year award. The National Highway Traffic Safety Administration (NTSHA) in 2013, 2014, and 2015 awarded the Tesla Model S a 5-star safety rating, both overall and in every subcategory (a score achieved by approximately 1 percent of all cars tested by the NHTSA). Consumer Reports gave the Model S a score of 99 out of 100 points in 2013, 2014, and 2015. saying it was "better than anything we've ever tested." However, the Tesla Model S did not make the Consumer Reports list of the "10 Top Picks" in 2016, 2017. and 2018, but the Model S did earn a perfect 100 score on the 2018 road test drive. The sleek styling and politically correct power source of Tesla's Model S and Model X were thought to explain why thousands of wealthy individuals in countries where the two models were being sold- anxious to be a part of the migration from gasoline- powered vehicles to electric-powered vehicles and to publicly display support for a cleaner environment- had become early purchasers and advocates for Tesla's vehicles. Indeed, word-of-mouth praise among current owners and glowing articles in the media were so pervasive that Tesla had not yet spent any money on advertising to boost customer traffic in its showrooms. In a presentation to investors, a Tesla officer said "Tesla owners are our best salespeople." As Tesla's current chairman and CEO, Elon Musk's strategic vision for the automotive segment of Tesla's operations featured three major elements: 1. Bring a full-range of affordable electric powered vehicles to market and become the world's foremost manufacturer of premium quality, high-performance electric vehicles. 2. Convince motor vehicle owners worldwide that EXHIBITI Tesla's Deliveries of the Model S, Model X, and Model 3 to Customers, 2012 through the First Quarter of 2018 Model S Model S plus Model 3 Period Model X Deliveries Deliveries Deliveries 2012 2013 2,653 22,477 Cases in Crafting and Executing Strategy numbers of units coming off the assembly line had quality problems involving malfunctioning parts/ components and/or faulty installation issues that required reworking. A big parking lot just outside the assembly plant in Fremont, California, was said to be full of Model 3s awaiting corrective attention: a few were even being junked because of the high cost of restoring them to a condition that would pass final pre-delivery inspection. On February 7, 2018, Musk reported: We continue to target weekly Model 3 production rates of 2,500 by the end of Q1 and 5,000 by the end of Q2. It is important to note that while these are the levels we are focused on hitting and we have plans in place to achieve them, our prior experience on the Model 3 ramp has demonstrated the difficulty of accurately forecasting specific production rates at specific points in time. What we can say with confidence is that we are taking many actions to systematically address bottlenecks and add capacity in places like the battery module line where we have experienced constraints, and these actions should result in our production rate significantly increasing dur- ing the rest of QI and through Q2. Despite the delays that we experienced in our pro- duction ramp, Model 3 net reservations remained stable in Q4. In recent weeks, they have continued to grow as Model 3 has arrived in select Tesla stores and received numerous positive reviews, including Automobile maga- zine's 2018 Design of the Year award. A week or so later, Tesla shut down the Model 3 assembly line for four days to address some of the assembly problems being encountered. Nonetheless, in early March 2018, there were reports from mul- tiple sources that Tesla had not been able to consis- tently achieve a production run rate of 800 units per week. So Musk's target of a weekly production rate of 2.500 Models 3 by the end of March seemed very much in jeopardy. In addition, there were accumulating reports from the owners of Model 3s relating to touch- screen issues-one related to the audio system vol- ume suddenly blasting higher without the screen having been touched: another related to drivers returning to their parked Model 3 and discovering noticeably while the car was parked in the sun on a hot day for several hours, had been reported by a number of Model 3 owners and, to a lesser extent, by a few Model S and Model X owners. It appeared that battery drain problems often occurred in Model 3 vehicles experiencing touchscreen issues. A cou- ple of Model 3 owners with technical backgrounds had speculated the problem related to touchscreens being mounted on a large metal pedestal such that large temperature differentials between a vehicle's hot interior and its cooler exterior caused the touch- screen and plastic touchpad to warp and produce other anomalies as the metal pedestal absorbed heat from inside the vehicle. As of March 27, 2018, the cause had not been pinpointed, but if the problem did relate to a faulty pedestal design, then correct- ing the design problem could cause further delays in ramping up Model 3 production and drive up war- ranty costs for Model 3s already delivered. During the last week of March, Elon Musk tweeted that he had taken over the role of supervising Model 3 pro- duction for the time being. The first week of April 2018. Tesla reported that it produced 34,494 vehicles in the first quarter of 2018. Tesla's QI deliveries were 29,980 vehicles, of which 11,730 were Model S: 10.070, were Model X; and 8,180 were Model 3: as of March 31. 4.060 Model S and Model X vehicles and 2.040 Model 3 vehicles were in transit to customers. Tesla also reported that after shifting some production resources away from Model S and Model X production over to production and assembly of the Model 3 during the last week of March, it was able to produce 2.020 Models 3s in the last seven days leading up to April 3. In its produc- tion and delivery announcement, the company fur- ther said: Given the progress made thus far and upcoming actions for further capacity improvement, we expect that the Model 3 production rate will climb rapidly through Q2. Tesla continues to target a production rate of approxi- mately 5,000 units per week in about three months. Finally, we would like to share two additional points about Model 3: Net Model 3 reservations remained stable through Q1. The reasons for order cancellation are almost entirely due to delays in production in general and delays in availability of certain planned options, particularly dual motor AWD and the smaller battery pack. Despite the difficulties being experienced with the Model 3, production and sales of the company's trailblazing Model S sedan (introduced in 2012) and Model X sports utility vehicle introduced in late 2015) were proceeding largely on plan. Combined sales of these two models reached nearly 101,500 units in 2017 (see Exhibit 1). The Model S was a fully electric, four-door, five-passenger luxury sedan with an all-glass panoramic roof, high definition backup camera, a 17-inch touchscreen that controlled most of the car's functions, keyless entry. xenon head- lights, dual USB ports, tire pressure monitoring, and numerous other features that were standard in most luxury vehicles. The cheapest Model S had a base price of $75,700 in 2018 and, when equipped with options frequented selected by customers, carried a retail sticker price ranging from $95,000 to $136.000. The Model X was the longest range all-electric pro duction sport utility vehicle in the world; it could seat up to seven adults and incorporated a unique falcon wing door system for easy access to the second and third seating rows. The Model X had an all-wheel drive dual motor system and autopilot capabilities, along with a full assortment of standard and optional features. Retail sticker prices in 2018 ranged from a base price of $80,700 to $97,000 for a well-equipped Model X to $140,000 for a fully loaded model. Both the Model S and Model X were being sold in North America, Europe, and Asia in 2017 and 2018. The Model S was the most awarded car of 2013, including Motor Trend's 2013 Car of the Year award and Automobile magazine's 2013 Car of the Year award. The National Highway Traffic Safety Administration (NTSHA) in 2013, 2014, and 2015 awarded the Tesla Model S a 5-star safety rating, both overall and in every subcategory (a score achieved by approximately 1 percent of all cars tested by the NHTSA). Consumer Reports gave the Model S a score of 99 out of 100 points in 2013, 2014, and 2015. saying it was "better than anything we've ever tested. However, the Tesla Model S did not make the Consumer Reports list of the "10 Top Picks" in 2016, 2017. and 2018, but the Model S did earn a perfect 100 score on the 2018 road test drive. The sleek styling and politically correct power source of Tesla's Model S and Model X were thought to explain why thousands of wealthy individuals in countries where the two models were being sold- anxious to be a part of the migration from gasoline- powered vehicles to electric-powered vehicles and to publicly display support for a cleaner environment- had become early purchasers and advocates for Tesla's vehicles. Indeed, word-of-mouth praise among current owners and glowing articles in the media were so pervasive that Tesla had not yet spent any money on advertising to boost customer traffic in its showrooms. In a presentation to investors, a Tesla officer said "Tesla owners are our best salespeople." As Tesla's current chairman and CEO, Elon Musk's strategic vision for the automotive segment of Tesla's operations featured three major elements: 1. Bring a full-range of affordable electric-powered vehicles to market and become the world's foremost manufacturer of premium quality, high-performance electric vehicles. 2. Convince motor vehicle owners worldwide that EXHIBITI Tesla's Deliveries of the Model S, Model X, and Model 3 to Customers, 2012 through the First Quarter of 2018 Model S plus Model S Model 3 Period Model X Deliveries Deliveries Deliveries 2012 2013 2,653 22,477 li Arthur A. Thompson The University of Alabama esla Motors began assembling the first mod- els of its new affordably-priced" entry-level Model 3 electric car in May 2017 and delivered the first units the last week of July, with a goal of gradually ramping up production to a total of 1.500 units by the end of September. The first production vehicles, delivered to employees who had placed pre- production reservations over a year earlier, were pre- configured with rear-wheel drive and a long-range battery: had a range of 310 miles and 0 to 60 mph acceleration time of 5.1 seconds; and a sticker price starting at $44,000 with premium upgrades available for an additional $5.000. Deliveries of the standard Model 3, with a base price of $35.000. 220 miles of range, and a 0 to 60 mph acceleration time of 5.6 sec. onds, were expected to begin in the United States in November 2017. Dual motor all-wheel drive configu- rations were scheduled to be available in early 2018. Plans called for international deliveries of the Model 3 to begin in late 2018, contingent upon regulatory approvals, starting with left-hand drive markets and followed by right-hand drive markets in 2019. Tesla had unveiled six drivable prototypes of the Model 3 for public viewing and a limited number of test drives on the evening of March 31, 2016. Buyer reaction was overwhelmingly positive. Over the next two weeks, some 350.000 individuals paid a $1,000 deposit to reserve a place in line to obtain a Model 3: reportedly, the number of reservations grew to nearly 400,000 units over the next several months. Because of the tremendous amount of interest in the Model 3. Tesla Chairman and CEO Elon Musk announced in May 2016 that Tesla was advancing its schedule to begin producing the Model 3 from late 2017 to mid- 2017 and further that it was going to accelerate its efforts to expand production capacity of the Model 3, with a goal of getting to a production run rate of 500,000 units annually by year-end 2018 instead of year-end 2020. In early August 2017, in a letter updating share- holders on the company's second quarter 2017 results, Musk said: Based on our preparedness at this time, we are confi- dent we can produce just over 1,500 [ Model 31 vehicles in Q3 and achieve a run rate of 5.000 vehicles per week by the end of 2017. We also continue to plan on increas- ing Model 3 production to 10,000 vehicles per week at some point in 2018. But in his third quarter 2017 update on November 1, 2017, Musk related a host of produc- tion bottlenecks and challenges that were blocking the ramp-up of Model 3 production and delaying deliveries, saying, "this makes it difficult to predict exactly how long it will take for all bottlenecks to be cleared or when new ones will appear. Based on what we know now, we currently expect to achieve a pro- duction rate of 5,000 Model 3 vehicles per week by late Q1 2018.02 But Tesla's "production hell" with the Model 3 continued to haunt the company in early 2018. Many analysts believed Tesla's problems stemmed from having taken huge shortcuts in the parts approval process, production line validation, and full beta test- ing of the Model 3 in order to begin early assembly and production ramp-up. There were other reasons, including ongoing parts bottlenecks and inconsis- tent manufacturing quality. Production line employ- ees interviewed by reporters indicated significant Copyright 2019 by Arthur A. Thompson. All rights reserved. Cases in Crafting and Executing Strategy numbers of units coming off the assembly line had quality problems involving malfunctioning parts/ components and/or faulty installation issues that required reworking. A big parking lot just outside the assembly plant in Fremont, California, was said to be full of Model 3s awaiting corrective attention: a few were even being junked because of the high cost of restoring them to a condition that would pass final predelivery inspection. On February 7, 2018, Musk reported: We continue to target weekly Model 3 production rates of 2.500 by the end of Q1 and 5,000 by the end of Q2. It is important to note that while these are the levels we are focused on hitting and we have plans in place to achieve them, our prior experience on the Model 3 ramp has demonstrated the difficulty of accurately forecasting specific production rates at specific points in time. What we can say with confidence is that we are taking many actions to systematically address bottlenecks and add capacity in places like the battery module line where we have experienced constraints, and these actions should result in our production rate significantly increasing dur- ing the rest of Q1 and through Q2. Despite the delays that we experienced in our pro- duction ramp, Model 3 net reservations remained stable in Q4. In recent weeks, they have continued to grow as Model 3 has arrived in select Tesla stores and received numerous positive reviews, including Automobile maga- zine's 2018 Design of the Year award. A week or so later, Tesla shut down the Model 3 assembly line for four days to address some of the assembly problems being encountered. Nonetheless, in early March 2018, there were reports from mul- tiple sources that Tesla had not been able to consis tently achieve a production run rate of 800 units per week. So Musk's target of a weekly production rate of 2.500 Models 3 by the end of March seemed very much in jeopardy. In addition, there were accumulating reports from the owners of Model 3s relating to touch- screen issues-one related to the audio system vol- ume suddenly blasting higher without the screen having been touched: another related to drivers returning to their parked Model 3 and discovering noticeably while the car was parked in the sun on a hot day for several hours, had been reported by a number of Model 3 owners and, to a lesser extent, by a few Model S and Model X owners. It appeared that battery drain problems often occurred in Model 3 vehicles experiencing touchscreen issues. A cou- ple of Model 3 owners with technical backgrounds had speculated the problem related to touchscreens being mounted on a large metal pedestal such that large temperature differentials between a vehicle's hot interior and its cooler exterior caused the touch- screen and plastic touchpad to warp and produce other anomalies as the metal pedestal absorbed heat from inside the vehicle. As of March 27, 2018, the cause had not been pinpointed, but if the problem did relate to a faulty pedestal design, then correct- ing the design problem could cause further delays in ramping up Model 3 production and drive up war- ranty costs for Model 3s already delivered. During the last week of March, Elon Musk tweeted that he had taken over the role of supervising Model 3 pro- duction for the time being. The first week of April 2018. Tesla reported that it produced 34,494 vehicles in the first quarter of 2018. Tesla's QI deliveries were 29,980 vehicles, of which 11,730 were Model S: 10.070, were Model X; and 8.180 were Model 3: as of March 31. 4.060 Model S and Model X vehicles and 2.040 Model 3 vehicles were in transit to customers. Tesla also reported that after shifting some production resources away from Model S and Model X production over to production and assembly of the Model 3 during the last week of March, it was able to produce 2.020 Models 3s in the last seven days leading up to April 3. In its produc- tion and delivery announcement, the company fur- ther said: Given the progress made thus far and upcoming actions for further capacity improvement, we expect that the Model 3 production rate will climb rapidly through Q2. Tesla continues to target a production rate of approxi- mately 5,000 units per week in about three months. Finally, we would like to share two additional points about Model 3: Net Model 3 reservations remained stable through Q1. The reasons for order cancellation are almost entirely due to delays in production in general and delays in availability of certain planned options, particularly dual motor AWD and the smaller battery pack.* Despite the difficulties being experienced with the Model 3, production and sales of the company's trailblazing Model S sedan (introduced in 2012) and Model X sports utility vehicle (introduced in late 2015) were proceeding largely on plan. Combined sales of these two models reached nearly 101,500 units in 2017 (see Exhibit 1). The Model S was a fully electric, four-door, five-passenger luxury sedan with an all-glass panoramic roof, high definition backup camera, a 17-inch touchscreen that controlled most of the car's functions, keyless entry. xenon head- lights, dual USB ports, tire pressure monitoring, and numerous other features that were standard in most luxury vehicles. The cheapest Model S had a base price of $75,700 in 2018 and, when equipped with options frequented selected by customers, carried a retail sticker price ranging from $95,000 to $136.000. The Model X was the longest range all-electric pro- duction sport utility vehicle in the world; it could seat up to seven adults and incorporated a unique falcon wing door system for easy access to the second and third seating rows. The Model X had an all-wheel drive dual motor system and autopilot capabilities, along with a full assortment of standard and optional features. Retail sticker prices in 2018 ranged from a base price of $80,700 to $97,000 for a well-equipped Model X to $140,000 for a fully loaded model. Both the Model S and Model X were being sold in North America, Europe, and Asia in 2017 and 2018. The Model S was the most-awarded car of 2013, including Motor Trend's 2013 Car of the Year award and Automobile magazine's 2013 Car of the Year award. The National Highway Traffic Safety Administration (NTSHA) in 2013, 2014, and 2015 awarded the Tesla Model S a 5-star safety rating, both overall and in every subcategory (a score achieved by approximately 1 percent of all cars tested by the NHTSA). Consumer Reports gave the Model S a score of 99 out of 100 points in 2013, 2014, and 2015. saying it was "better than anything we've ever tested." However, the Tesla Model S did not make the Consumer Reports list of the "10 Top Picks" in 2016, 2017. and 2018, but the Model S did earn a perfect 100 score on the 2018 road test drive. The sleek styling and politically correct power source of Tesla's Model S and Model X were thought to explain why thousands of wealthy individuals in countries where the two models were being sold- anxious to be a part of the migration from gasoline- powered vehicles to electric-powered vehicles and to publicly display support for a cleaner environment- had become early purchasers and advocates for Tesla's vehicles. Indeed, word-of-mouth praise among current owners and glowing articles in the media were so pervasive that Tesla had not yet spent any money on advertising to boost customer traffic in its showrooms. In a presentation to investors, a Tesla officer said "Tesla owners are our best salespeople." As Tesla's current chairman and CEO, Elon Musk's strategic vision for the automotive segment of Tesla's operations featured three major elements: 1. Bring a full-range of affordable electric powered vehicles to market and become the world's foremost manufacturer of premium quality, high-performance electric vehicles. 2. Convince motor vehicle owners worldwide that EXHIBITI Tesla's Deliveries of the Model S, Model X, and Model 3 to Customers, 2012 through the First Quarter of 2018 Model S Model S plus Model 3 Period Model X Deliveries Deliveries Deliveries 2012 2013 2,653 22,477 Cases in Crafting and Executing Strategy numbers of units coming off the assembly line had quality problems involving malfunctioning parts/ components and/or faulty installation issues that required reworking. A big parking lot just outside the assembly plant in Fremont, California, was said to be full of Model 3s awaiting corrective attention: a few were even being junked because of the high cost of restoring them to a condition that would pass final pre-delivery inspection. On February 7, 2018, Musk reported: We continue to target weekly Model 3 production rates of 2,500 by the end of Q1 and 5,000 by the end of Q2. It is important to note that while these are the levels we are focused on hitting and we have plans in place to achieve them, our prior experience on the Model 3 ramp has demonstrated the difficulty of accurately forecasting specific production rates at specific points in time. What we can say with confidence is that we are taking many actions to systematically address bottlenecks and add capacity in places like the battery module line where we have experienced constraints, and these actions should result in our production rate significantly increasing dur- ing the rest of QI and through Q2. Despite the delays that we experienced in our pro- duction ramp, Model 3 net reservations remained stable in Q4. In recent weeks, they have continued to grow as Model 3 has arrived in select Tesla stores and received numerous positive reviews, including Automobile maga- zine's 2018 Design of the Year award. A week or so later, Tesla shut down the Model 3 assembly line for four days to address some of the assembly problems being encountered. Nonetheless, in early March 2018, there were reports from mul- tiple sources that Tesla had not been able to consis- tently achieve a production run rate of 800 units per week. So Musk's target of a weekly production rate of 2.500 Models 3 by the end of March seemed very much in jeopardy. In addition, there were accumulating reports from the owners of Model 3s relating to touch- screen issues-one related to the audio system vol- ume suddenly blasting higher without the screen having been touched: another related to drivers returning to their parked Model 3 and discovering noticeably while the car was parked in the sun on a hot day for several hours, had been reported by a number of Model 3 owners and, to a lesser extent, by a few Model S and Model X owners. It appeared that battery drain problems often occurred in Model 3 vehicles experiencing touchscreen issues. A cou- ple of Model 3 owners with technical backgrounds had speculated the problem related to touchscreens being mounted on a large metal pedestal such that large temperature differentials between a vehicle's hot interior and its cooler exterior caused the touch- screen and plastic touchpad to warp and produce other anomalies as the metal pedestal absorbed heat from inside the vehicle. As of March 27, 2018, the cause had not been pinpointed, but if the problem did relate to a faulty pedestal design, then correct- ing the design problem could cause further delays in ramping up Model 3 production and drive up war- ranty costs for Model 3s already delivered. During the last week of March, Elon Musk tweeted that he had taken over the role of supervising Model 3 pro- duction for the time being. The first week of April 2018. Tesla reported that it produced 34,494 vehicles in the first quarter of 2018. Tesla's QI deliveries were 29,980 vehicles, of which 11,730 were Model S: 10.070, were Model X; and 8,180 were Model 3: as of March 31. 4.060 Model S and Model X vehicles and 2.040 Model 3 vehicles were in transit to customers. Tesla also reported that after shifting some production resources away from Model S and Model X production over to production and assembly of the Model 3 during the last week of March, it was able to produce 2.020 Models 3s in the last seven days leading up to April 3. In its produc- tion and delivery announcement, the company fur- ther said: Given the progress made thus far and upcoming actions for further capacity improvement, we expect that the Model 3 production rate will climb rapidly through Q2. Tesla continues to target a production rate of approxi- mately 5,000 units per week in about three months. Finally, we would like to share two additional points about Model 3: Net Model 3 reservations remained stable through Q1. The reasons for order cancellation are almost entirely due to delays in production in general and delays in availability of certain planned options, particularly dual motor AWD and the smaller battery pack. Despite the difficulties being experienced with the Model 3, production and sales of the company's trailblazing Model S sedan (introduced in 2012) and Model X sports utility vehicle introduced in late 2015) were proceeding largely on plan. Combined sales of these two models reached nearly 101,500 units in 2017 (see Exhibit 1). The Model S was a fully electric, four-door, five-passenger luxury sedan with an all-glass panoramic roof, high definition backup camera, a 17-inch touchscreen that controlled most of the car's functions, keyless entry. xenon head- lights, dual USB ports, tire pressure monitoring, and numerous other features that were standard in most luxury vehicles. The cheapest Model S had a base price of $75,700 in 2018 and, when equipped with options frequented selected by customers, carried a retail sticker price ranging from $95,000 to $136.000. The Model X was the longest range all-electric pro duction sport utility vehicle in the world; it could seat up to seven adults and incorporated a unique falcon wing door system for easy access to the second and third seating rows. The Model X had an all-wheel drive dual motor system and autopilot capabilities, along with a full assortment of standard and optional features. Retail sticker prices in 2018 ranged from a base price of $80,700 to $97,000 for a well-equipped Model X to $140,000 for a fully loaded model. Both the Model S and Model X were being sold in North America, Europe, and Asia in 2017 and 2018. The Model S was the most awarded car of 2013, including Motor Trend's 2013 Car of the Year award and Automobile magazine's 2013 Car of the Year award. The National Highway Traffic Safety Administration (NTSHA) in 2013, 2014, and 2015 awarded the Tesla Model S a 5-star safety rating, both overall and in every subcategory (a score achieved by approximately 1 percent of all cars tested by the NHTSA). Consumer Reports gave the Model S a score of 99 out of 100 points in 2013, 2014, and 2015. saying it was "better than anything we've ever tested. However, the Tesla Model S did not make the Consumer Reports list of the "10 Top Picks" in 2016, 2017. and 2018, but the Model S did earn a perfect 100 score on the 2018 road test drive. The sleek styling and politically correct power source of Tesla's Model S and Model X were thought to explain why thousands of wealthy individuals in countries where the two models were being sold- anxious to be a part of the migration from gasoline- powered vehicles to electric-powered vehicles and to publicly display support for a cleaner environment- had become early purchasers and advocates for Tesla's vehicles. Indeed, word-of-mouth praise among current owners and glowing articles in the media were so pervasive that Tesla had not yet spent any money on advertising to boost customer traffic in its showrooms. In a presentation to investors, a Tesla officer said "Tesla owners are our best salespeople." As Tesla's current chairman and CEO, Elon Musk's strategic vision for the automotive segment of Tesla's operations featured three major elements: 1. Bring a full-range of affordable electric-powered vehicles to market and become the world's foremost manufacturer of premium quality, high-performance electric vehicles. 2. Convince motor vehicle owners worldwide that EXHIBITI Tesla's Deliveries of the Model S, Model X, and Model 3 to Customers, 2012 through the First Quarter of 2018 Model S plus Model S Model 3 Period Model X Deliveries Deliveries Deliveries 2012 2013 2,653 22,477 li