Question: SEMESTER ONE & TWO ASSIGNMENT 2 QUESTION 1 1.1 Explain how higher quality can lead to reduced costs. 1.2 List four (4) examples of costs

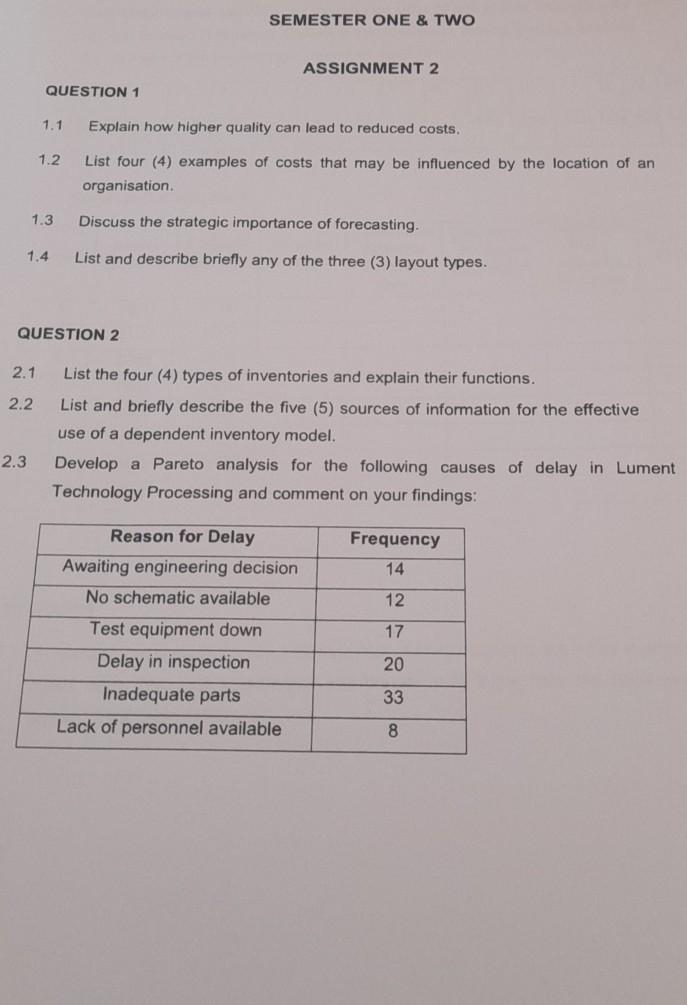

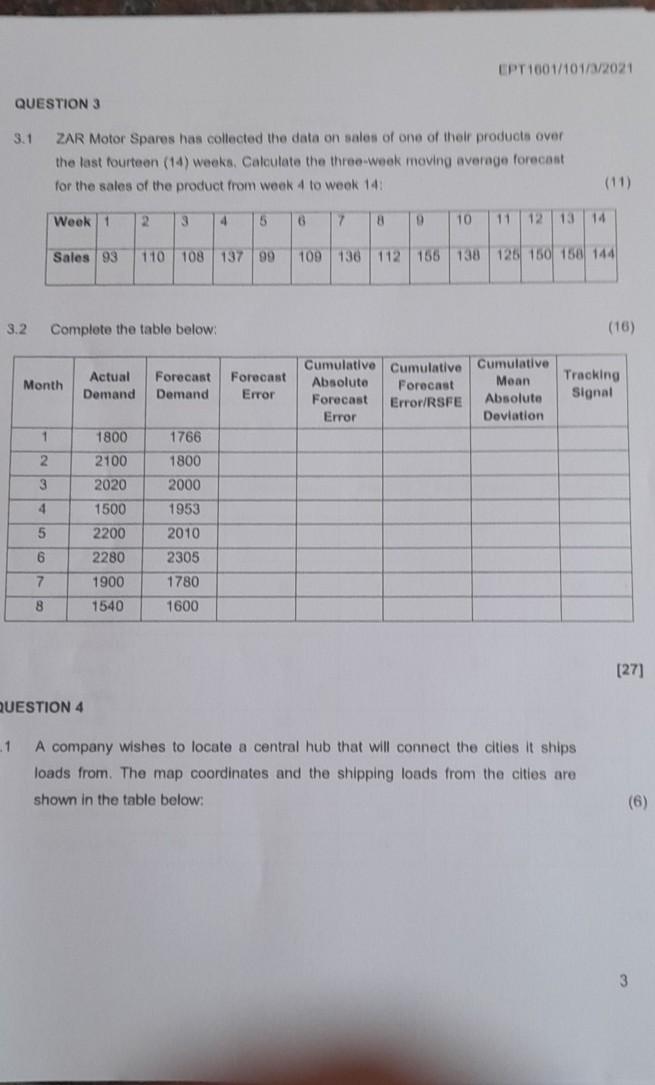

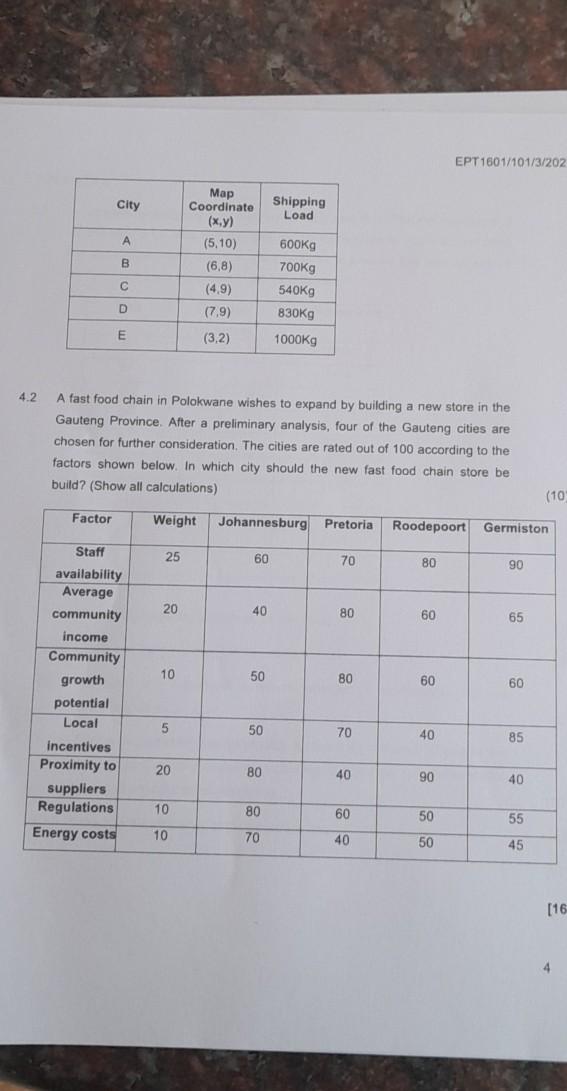

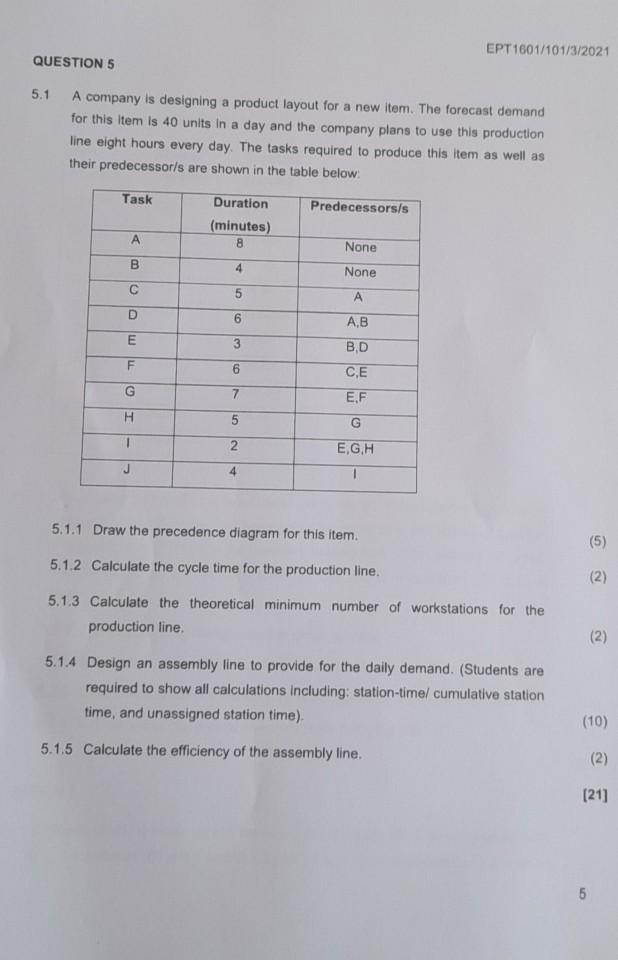

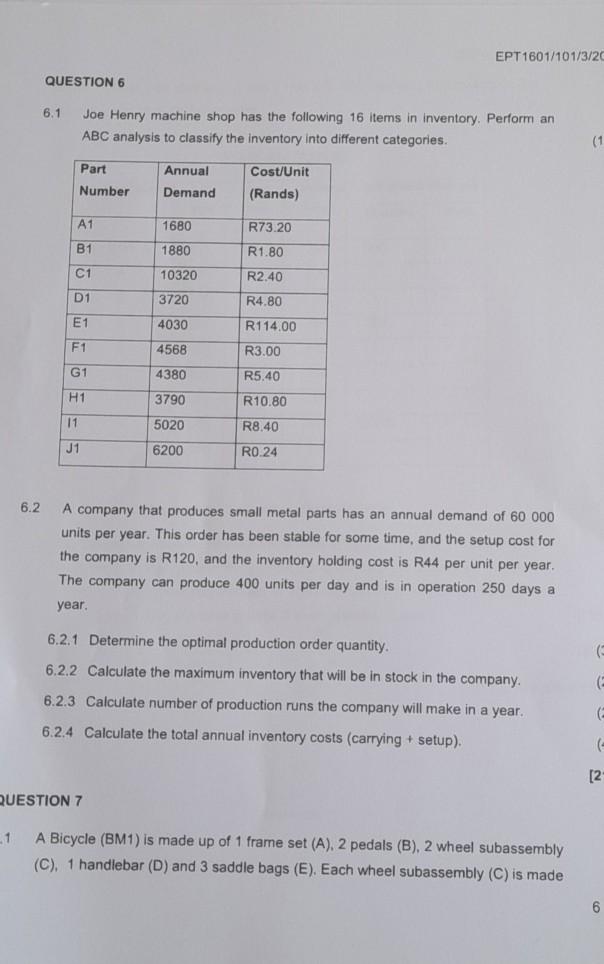

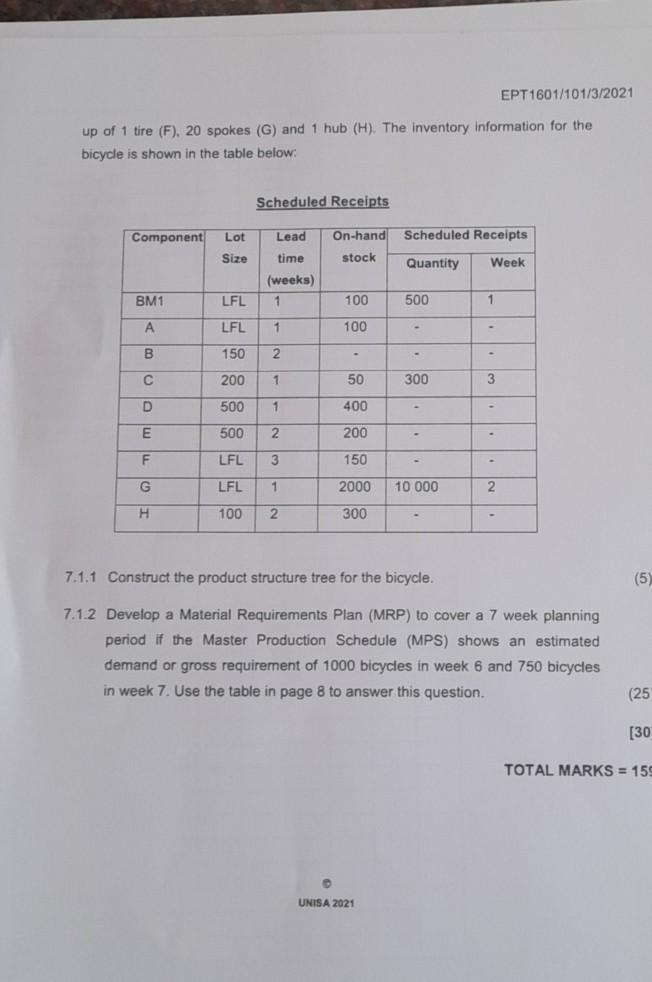

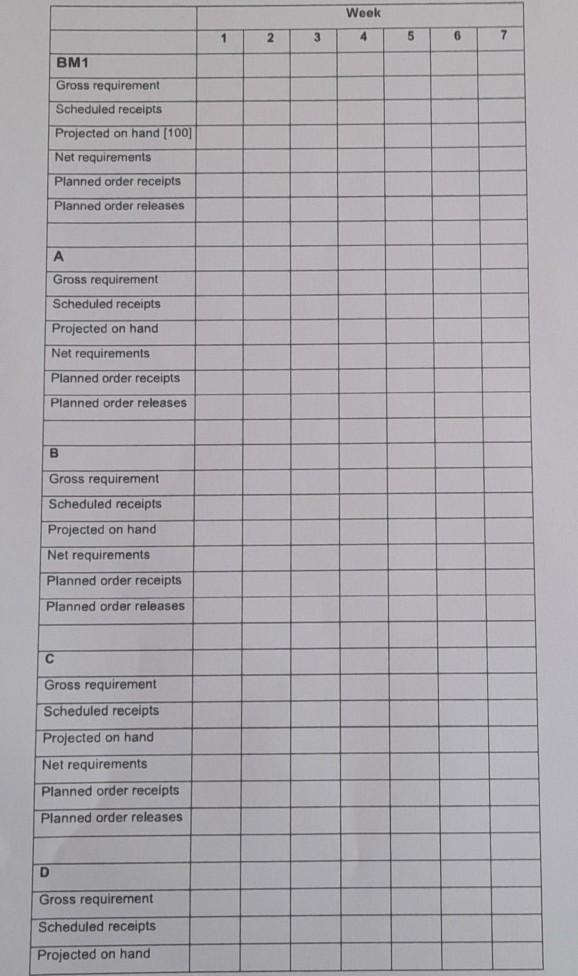

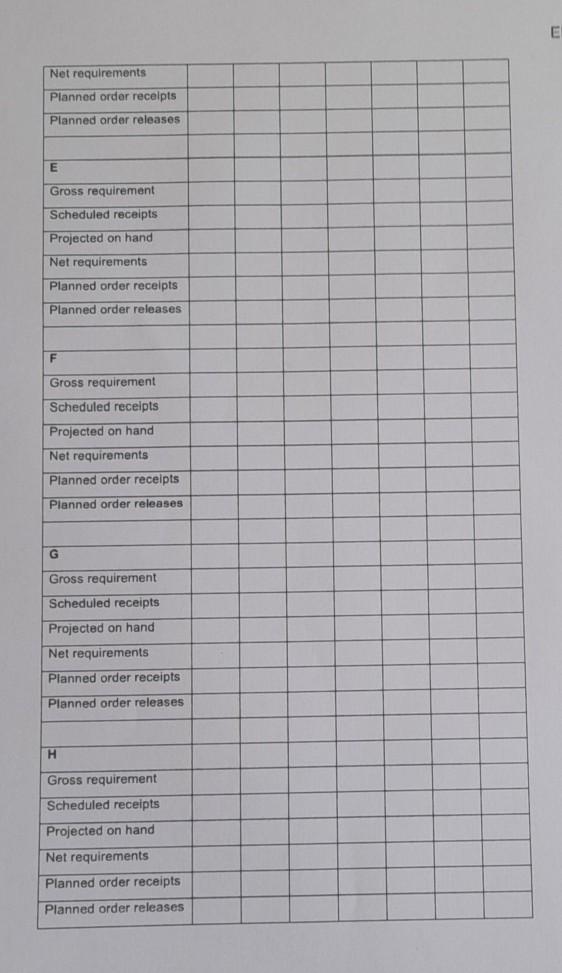

SEMESTER ONE & TWO ASSIGNMENT 2 QUESTION 1 1.1 Explain how higher quality can lead to reduced costs. 1.2 List four (4) examples of costs that may be influenced by the location of an organisation 1.3 Discuss the strategic importance of forecasting. 1.4 List and describe briefly any of the three (3) layout types. QUESTION 2 2.1 List the four (4) types of inventories and explain their functions. 2.2 List and briefly describe the five (5) sources of information for the effective use of a dependent inventory model. Develop a Pareto analysis for the following causes of delay in Lument Technology Processing and comment on your findings: 2.3 Frequency 14 12 Reason for Delay Awaiting engineering decision No schematic available Test equipment down Delay in inspection Inadequate parts Lack of personnel available 17 20 33 8 UPT1001/101/3/2021 QUESTION 3 3.1 ZAR Motor Spares has collected the data on sales of one of their products over the last fourteen (14) weeks. Calculate the three-week moving average forecast for the sales of the product from week 4 to week 14 Week 1 2 3 4 5 6 7 8 10 11 12 13 14 Sales 93 110 108 137 99 100 136 112 166 138 126 150 158 144 3.2 Complete the table below (16) Month Actual Demand Forecast Demand Forecast Error Cumulativo Cumulative Cumulative Absolute Forecast Mean Forecast Error/RSFE Absolute Error Deviation Tracking Signal 1 1800 1766 2 3 4 5 2100 2020 1500 2200 2280 1800 2000 1953 2010 2305 1780 6 7 1900 8 1540 1600 [27] QUESTION 4 1 A company wishes to locate a central hub that will connect the cities it ships loads from. The map coordinates and the shipping loads from the cities are shown in the table below: (6) 3 EPT 1601/101/3/202 City Shipping Load Map Coordinate (x,y) (5.10) (6,8) (4.9) (7.9) B 600Kg 700Kg 540Kg 830kg D E (3,2) 1000Kg 4.2 A fast food chain in Polokwane wishes to expand by building a new store in the Gauteng Province. After a preliminary analysis, four of the Gauteng cities are chosen for further consideration. The cities are rated out of 100 according to the factors shown below. In which city should the new fast food chain store be build? (Show all calculations) (10 Factor Weight Johannesburg Pretoria Roodepoort Germiston 25 60 70 80 90 20 40 80 60 65 10 50 80 60 60 Staff availability Average community income Community growth potential Local incentives Proximity to suppliers Regulations Energy costs 5 50 70 40 85 20 80 40 90 40 10 80 60 50 55 10 70 40 50 45 [16 4 EPT 1601/101/3/2021 QUESTION 5 5.1 A company is designing a product layout for a new item. The forecast demand for this item is 40 units in a day and the company plans to use this production line eight hours every day. The tasks required to produce this item as well as their predecessorls are shown in the table below. Task Predecessors/s Duration (minutes) 8 None B 4 None 5 A 6 A.B 3 BD 6 CE G 7 E,F H 5 G 2 E,G,H 4 5.1.1 Draw the precedence diagram for this item (5) 5.1.2 Calculate the cycle time for the production line. (2) 5.1.3 Calculate the theoretical minimum number of workstations for the production line (2) 5.1.4 Design an assembly line to provide for the daily demand. (Students are required to show all calculations including station-time/ cumulative station time, and unassigned station time) (10) 5.1.5 Calculate the efficiency of the assembly line. (2) [21] 5 5 EPT1601/101/3/20 QUESTION 6 6.1 Joe Henry machine shop has the following 16 items in inventory. Perform an ABC analysis to classify the inventory into different categories. (1 Part Number Annual Demand Cost/Unit (Rands) A1 1680 R73.20 B1 1880 R1.80 C1 10320 R2.40 D1 3720 R4.80 E1 4030 R114.00 F1 4568 R3.00 G1 4380 R5.40 H1 3790 R10.80 11 5020 R8.40 J1 6200 R0.24 6.2 A company that produces small metal parts has an annual demand of 60 000 units per year. This order has been stable for some time, and the setup cost for the company is R120, and the inventory holding cost is R44 per unit per year. The company can produce 400 units per day and is in operation 250 days a year 6.2.1 Determine the optimal production order quantity. 6.2.2 Calculate the maximum inventory that will be in stock in the company. 6.2.3 Calculate number of production runs the company will make in a year. 6.2.4 Calculate the total annual inventory costs (carrying + setup). [2 QUESTION 7 1 A Bicycle (BM1) is made up of 1 frame set (A), 2 pedals (B), 2 wheel subassembly (C), 1 handlebar (D) and 3 saddle bags (E). Each wheel subassembly (C) is made 6 EPT1601/101/3/2021 up of 1 tire (F). 20 spokes (G) and 1 hub (H). The inventory Information for the bicycle is shown in the table below: Scheduled Receipts Component Lot Lead Scheduled Receipts On-hand stock Size Quantity Week time (weeks) 1 BM1 LFL 100 500 1 A LFL 1 100 - B 150 2 200 1 50 300 3 D 500 1 400 E 500 2 200 F LFL 3 150 - G LFL 1 2000 10 000 2 H 100 2 300 7.1.1 Construct the product structure tree for the bicycle. (5) 7.1.2 Develop a Material Requirements Plan (MRP) to cover a 7 week planning period if the Master Production Schedule (MPS) shows an estimated demand or gross requirement of 1000 bicycles in week 6 and 750 bicycles in week 7. Use the table in page 8 to answer this question. (25 [30 TOTAL MARKS = 159 UNISA 2021 Week 1 2 3 4 5 6 7 BM1 Gross requirement Scheduled receipts Projected on hand [100] Net requirements Planned order receipts Planned order releases A Gross requirement Scheduled receipts Projected on hand Net requirements Planned order receipts Planned order releases B Gross requirement Scheduled receipts Projected on hand Net requirements Planned order receipts Planned order releases Gross requirement Scheduled receipts Projected on hand Net requirements Planned order receipts Planned order releases D Gross requirement Scheduled receipts Projected on hand E Net requirements Planned order receipts Planned order releases E Gross requirement Scheduled receipts Projected on hand Net requirements Planned order receipts Planned order releases F Gross requirement Scheduled receipts Projected on hand Net requirements Planned order receipts Planned order releases G Gross requirement Scheduled receipts Projected on hand Net requirements Planned order receipts Planned order releases H Gross requirement Scheduled receipts Projected on hand Net requirements Planned order receipts Planned order releases

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock