Question: Shortest Processing Time (SPT) One heuristic for sequencing tasks is called Shortest Processing Time. Using this technique you schedule the task that takes the least

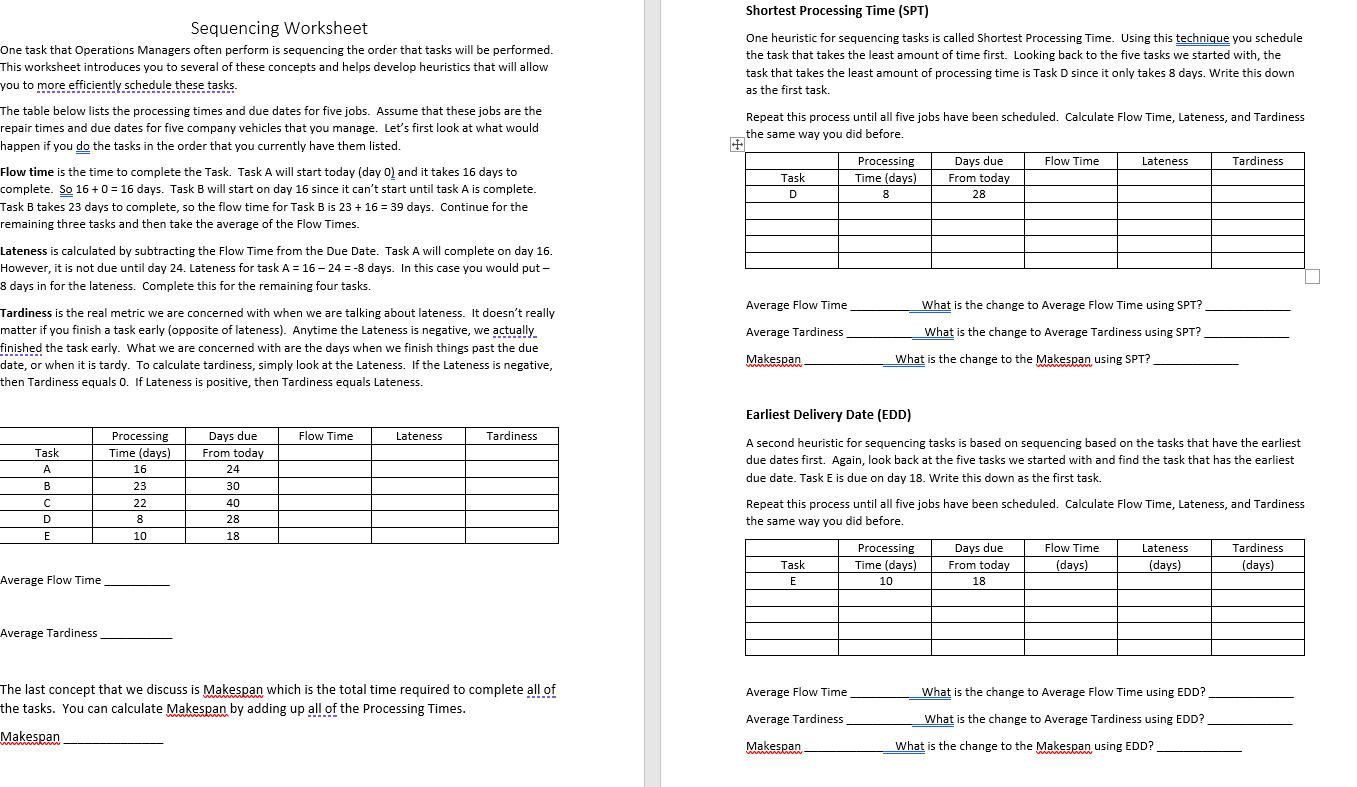

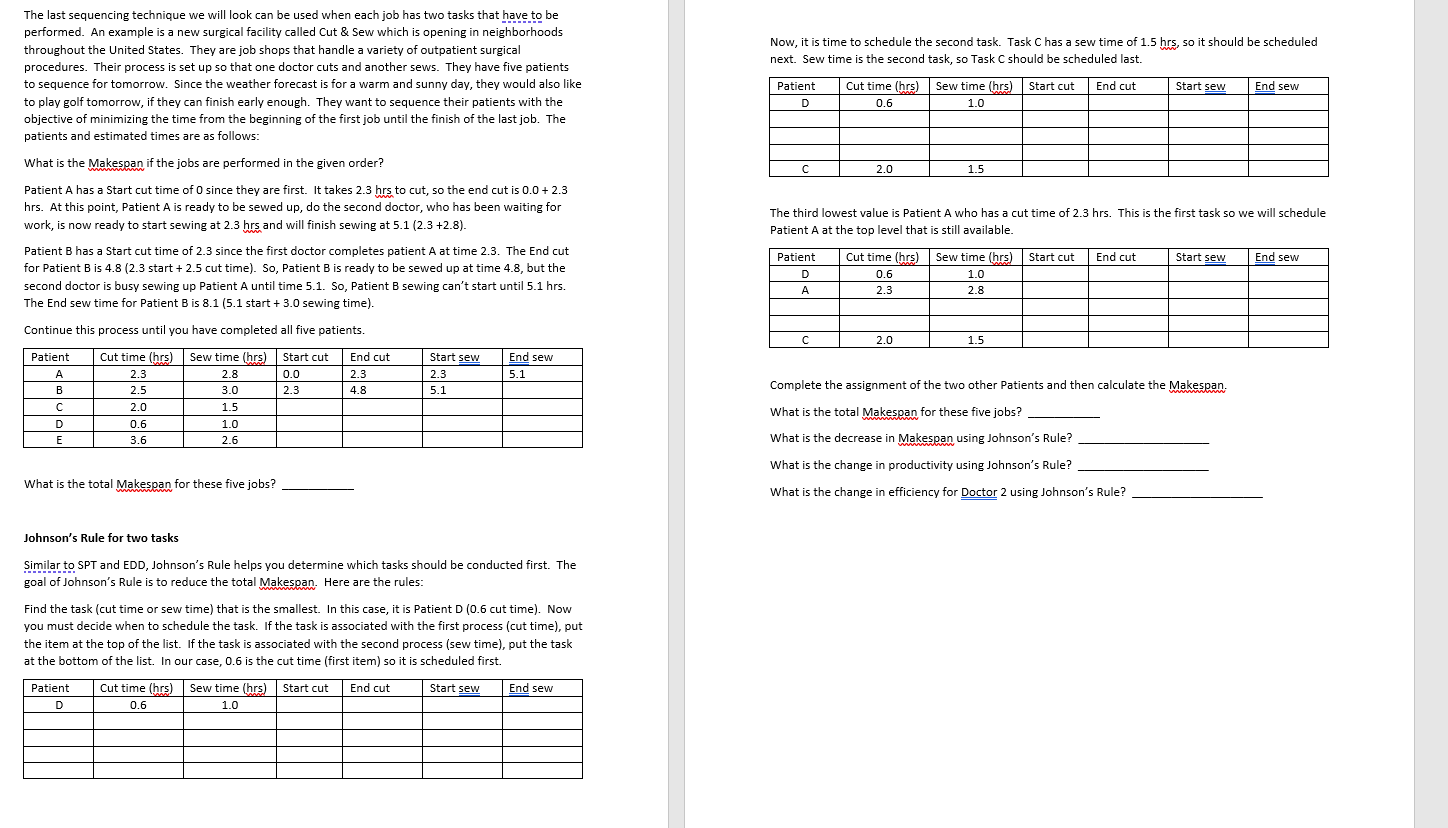

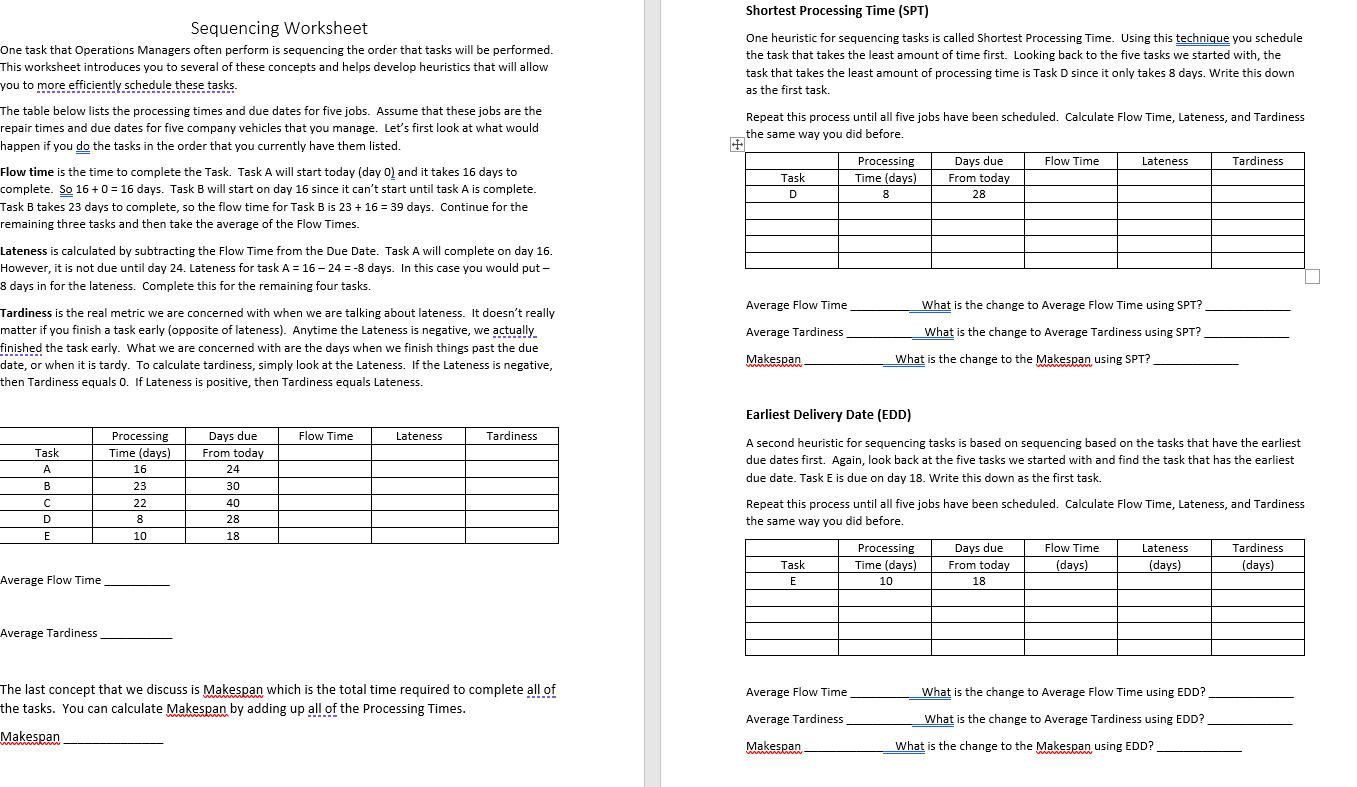

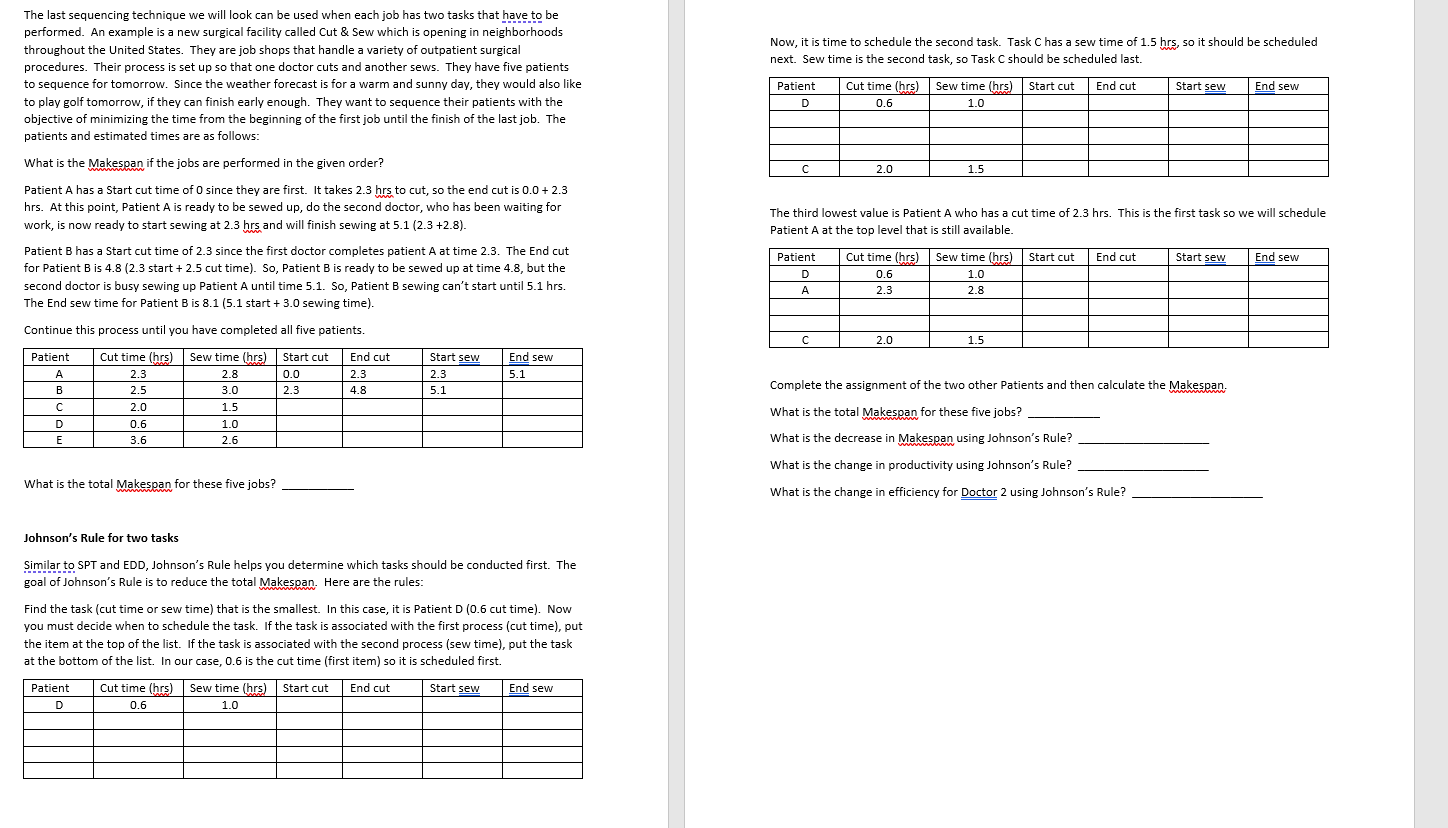

Shortest Processing Time (SPT) One heuristic for sequencing tasks is called Shortest Processing Time. Using this technique you schedule the task that takes the least amount of time first. Looking back to the five tasks we started with, the task that takes the least amount of processing time is Task D since it only takes 8 days. Write this down as the first task. Repeat this process until all five jobs have been scheduled. Calculate Flow Time, Lateness, and Tardiness the same way you did before. + Processing Days due Flow Time Lateness Tardiness Task Time (days) From today D 8 28 Sequencing Worksheet One task that Operations Managers often perform is sequencing the order that tasks will be performed. This worksheet introduces you to several of these concepts and helps develop heuristics that will allow you to more efficiently schedule these tasks. The table below lists the processing times and due dates for five jobs. Assume that these jobs are the repair times and due dates for five company vehicles that you manage. Let's first look at what would happen if you do the tasks in the order that you currently have them listed. Flow time is the time to complete the Task. Task A will start today (day O) and it takes 16 days to complete. So 16 + 0 = 16 days. Task B will start on day 16 since it can't start until task A is complete. Task B takes 23 days to complete, so the flow time for Task B is 23 + 16 = 39 days. Continue for the remaining three tasks and then take the average of the Flow Times. Lateness is calculated by subtracting the Flow Time from the Due Date. Task A will complete on day 16. However, it is not due until day 24. Lateness for task A = 16-24 = -8 days. In this case you would put - 8 days in for the lateness. Complete this for the remaining four tasks. Tardiness is the real metric we are concerned with when we are talking about lateness. It doesn't really matter if you finish a task early (opposite of lateness). Anytime the Lateness is negative, we actually finished the task early. What we are concerned with are the days when we finish things past the due date, or when it is tardy. To calculate tardiness, simply look at the Lateness. If the Lateness is negative, then Tardiness equals 0. If Lateness is positive, then Tardiness equals Lateness. Average Flow Time What is the change to Average Flow Time using SPT? Average Tardiness What is the change to Average Tardiness using SPT? Makesean What is the change to the Makespan using SPT? Earliest Delivery Date (EDD) Flow Time Lateness Tardiness Task A B Processing Time (days) 16 23 22 8 10 Days due From today 24 30 40 28 18 A second heuristic for sequencing tasks is based on sequencing based on the tasks that have the earliest due dates first. Again, look back at the five tasks we started with and find the task that has the earliest due date. Task E is due on day 18. Write this down as the first task. Repeat this process until all five jobs have been scheduled. Calculate Flow Time, Lateness, and Tardiness the same way you did before. . D E Processing Time (days) 10 Days due From today 18 Flow Time (days) Lateness (days) Tardiness (days) Task E Average Flow Time Average Tardiness Average Flow Time The last concept that we discuss is Makespan which is the total time required to complete all of the tasks. You can calculate Makespan by adding up all of the Processing Times. Makespan What is the change to Average Flow Time using EDD? What the change to Average Tardiness using EDD? Average Tardiness Makespan What is the change to the Makespan using EDD? wwwwwwwwww Now, it is time to schedule the second task. Task C has a sew time of 1.5 hrs, so it should be scheduled next. Sew time is the second task, so Task C should be scheduled last. The last sequencing technique we will look can be used when each job has two tasks that have to be performed. An example is a new surgical facility called Cut & Sew which is opening in neighborhoods throughout the United States. They are job shops that handle a variety of outpatient surgical procedures. Their process is set up so that one doctor cuts and another sews. They have five patients to sequence for tomorrow. Since the weather forecast is for a warm and sunny day, they would also like to play golf tomorrow, if they can finish early enough. They want to sequence their patients with the objective of minimizing the time from the beginning of the first job until the finish of the last job. The patients and estimated times are as follows: What is the Makespan if the jobs are performed in the given order? Start cut End cut Start sew End sew Patient D Cut time (hrs) Sew time (hrs) 0.6 1.0 2.0 1.5 The third lowest value is Patient A who has a cut time of 2.3 hrs. This is the first task so we will schedule Patient A at the top level that is still available. Patient A has a Start cut time of O since they are first. It takes 2.3 hrs to cut, so the end cut is 0.0 + 2.3 hrs. At this point, Patient A is ready to be sewed up, do the second doctor, who has been waiting for work, is now ready to start sewing at 2.3 hrs and will finish sewing at 5.1 (2.3 +2.8). Patient B has a Start cut time of 2.3 since the first doctor completes patient A at time 2.3. The End cut for Patient B is 4.8 (2.3 start + 2.5 cut time). So, Patient B is ready to be sewed up at time 4.8, but the second doctor is busy sewing up Patient A until time 5.1. So, Patient B sewing can't start until 5.1 hrs. The End sew time for Patient B is 8.1 (5.1 start + 3.0 sewing time). Start cut End cut Start sew End sew Patient D A Cut time (hrs) 0.6 2.3 Sew time (hrs) 1.0 2.8 Continue this process until you have completed all five patients. 2.0 1.5 Start cut 0.0 2.3 End cut 2.3 4.8 Start sew 2.3 5.1 End sew 5.1 Complete the assignment of the two other Patients and then calculate the Makespan. Patient A B C D E Cut time (hrs) 2.3 2.5 2.0 0.6 3.6 Sew time (hrs) 2.8 3.0 1.5 1.0 2.6 What is the total Makespan for these five jobs? What is the decrease in Makespan using Johnson's Rule? What is the change in productivity using Johnson's Rule? What is the change in efficiency for Doctor 2 using Johnson's Rule? What is the total Makespan for these five jobs? Johnson's Rule for two tasks Similar to SPT and EDD, Johnson's Rule helps you determine which tasks should be conducted first. The goal of Johnson's Rule is to reduce the total Makespan. Here are the rules: Find the task (cut time or sew time) that is the smallest. In this case, it is Patient D (0.6 cut time). Now you must decide when to schedule the task. If the task is associated with the first process (cut time), put the item at the top of the list. If the task is associated with the second process (sew time), put the task at the bottom of the list. In our case, 0.6 is the cut time (first item) so it is scheduled first. Start cut End cut Start sew End sew Patient D Cut time (hrs) 0.6 Sew time hrs) 1.0