Question: SHOULD BE SOLVED USING LINGO SOFTWARE CODE Find the quantity shipped from each factory to each region. How does the solution change if you are

SHOULD BE SOLVED USING LINGO SOFTWARE CODE

- Find the quantity shipped from each factory to each region.

- How does the solution change if you are required to locate a plant in each location? Comment on the solution.

- How does the solution change if you are required to set-up at least three plants?

- Make necessary changes to the data so that the site, New York is never selected? Report the result with the changes made.

Suggestions to solve the problem by the professor to posted below:

#1 a. Solve the base model ( I will post the base model given by the professor below), without restriction that you must open plant at each location.Follow the suggestions provided to build the model. A separate document has been posted with the problem statement and the data.

1b. Remember C11+C12=1 will force a plant on location1 but C11+C12

1c. A variation of 1b with changes in relationships with Cij variables.

1d. It is very similar to the transportation problem solve in home work#2. Make changes in the problem parameters that will make location 1 unattractive. Remember the objective function minimizes the combined fixed and transportation costs.

base model given by the professor below:

This problem ties together factory location, selection of production capacity for each location as well as allocation of capacity to different markets. There are four potential locations for new factory and two production capacities (high and low) are available at each location. The fixed cost to set-up a factory depends on the capacity selected, a higher cost to be incurred for higher capacity. There are four markets to be served. Demand for each market is known as well as the variable cost/unit. The objective is to design the network at a minimum cost. The cost elements include fixed cost and variable cost/unit. It may be viewed as four vendors and four customers transportation problem. The decision variables are as follows: Xij =quantity shipped from factory i to market j,

Cij a binary variable = 1 if ith market is set-up a low capacity and =0 if it is set-up at high capacity.

Supply constraint for Factory 1 is as follows:

X11+X12+X13+X14

Capacity1=200,000*C11+400,000*C12;

C11+C12=1;

Demand Constraint for Market 1 (East) is as follows:

X11+X21+X31+X41>=110,000;

Cost1 (associated with Factory 1)- Fixed + Variable Cost;

Cost1= 600,000*C11+10000,000*C12+211*X11+232*X12+240*X13+300*X14;

Complete the constraints for other factories as well as other markets.

Declare binary variables as shown next:

@bin(C11),

@bin(C12),.

(lingo code to be completed )

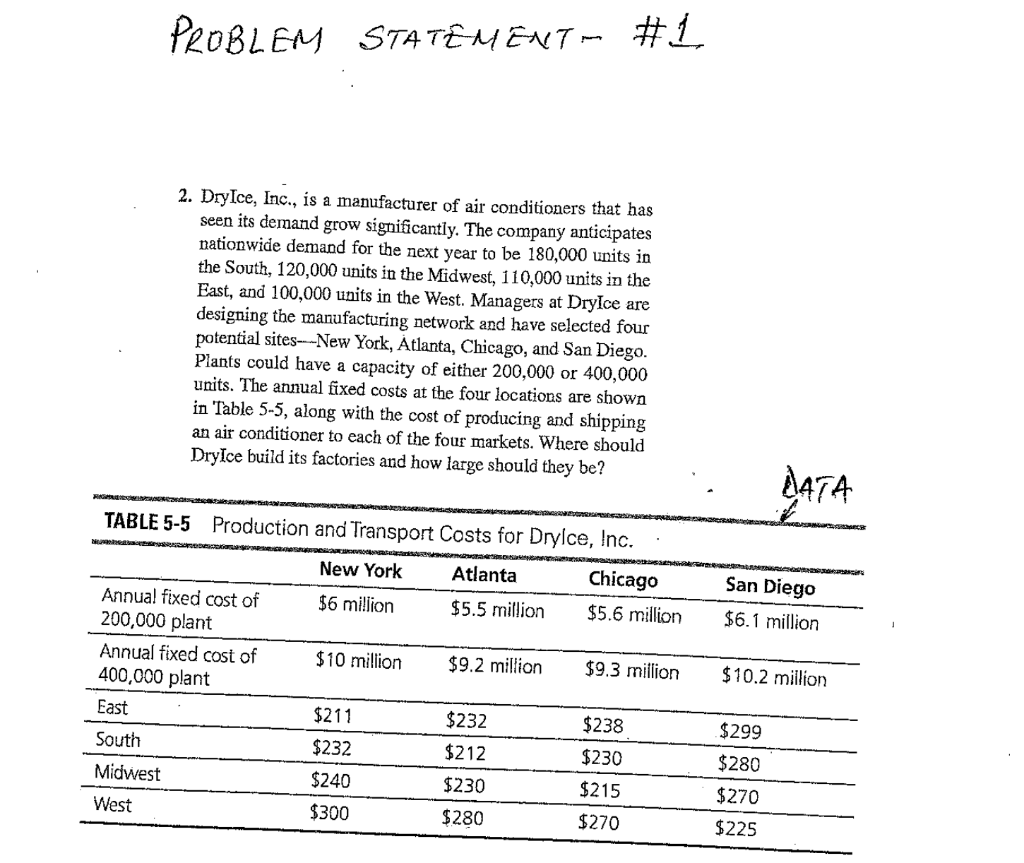

PROBLEM STATEMENT #1 2. DryIce, Inc., is a manufacturer of air conditioners that has seen its demand grow significantly. The company anticipates nationwide demand for the next year to be 180,000 units in the South, 120,000 units in the Midwest, 110,000 units in the East, and 100,000 units in the West. Managers at DryIce are designing the manufacturing network and have selected four potential sites- New York, Atlanta, Chicago, and San Diego. Plants could have a capacity of either 200,000 or 400,000 units. The annual fixed costs at the four locations are shown in Table 5-5, along with the cost of producing and shipping an air conditioner to each of the four markets. Where should DryIce build its factories and how large should they be? TABLE 5-5 Production and Transport Costs for Drvlne InnStep by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts