Question: Should KPG keep their distribution center in Phoenix, build a new distribution center near St. Louis or leasesome space in a distribution center (above ground

Should KPG keep their distribution center in Phoenix, build a new distribution center near St. Louis or leasesome space in a distribution center (above ground or underground) near St. Louis?

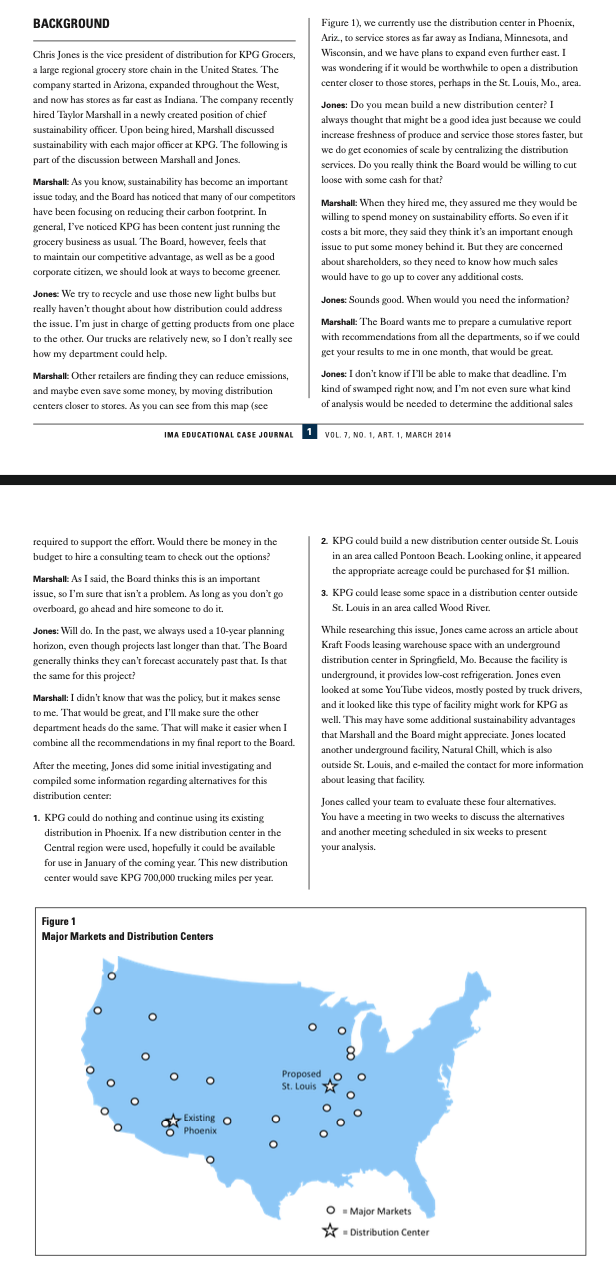

BACKGROUND Chris Jones is the vice president of distribution for KPG Grocers, a large regional grocery store chain in the United States. The company started in Arizona, expanded throughout the West, and now has stores as far east as Indiana. The company recently hired Taylor Marshall in a newly created position of chief sustainability officer. Upon being hired, Marshall discussed sustainability with each major officer at KPG. The following is part of the discussion between Marshall and Jones. Marshall: As you know, sustainability has become an important issue today, and the Board has noticed that many of our competitors have been focusing on reducing their carbon footprint. In general, I've noticed KPG has been content just running the grocery business as usual. The Board, however, feels that to maintain our competitive advantage, as well as be a good corporate citizen, we should look at ways to become greener. Jones: We try to recycle and use those new light bulbs but really haven't thought about how distribution could address the issue. I'm just in charge of getting products from one place to the other. Our trucks are relatively new, so I don't really see how my department could help Marshall: Other retailers are finding they can reduce emissions, and maybe even save some money, by moving distribution centers closer to stores. As you can see from this map (see Figure 1), we currently use the distribution center in Phoenix, Ariz, to service stores as far away as Indiana, Minnesota, and Wisconsin, and we have plans to expand even further cast. I was wondering if it would be worthwhile to open a distribution center closer to those stores, perhaps in the St. Louis, Mo., area. Jones: Do you mean build a new distribution center? I always thought that might be a good idea just because we could increase freshness of produce and service those stores faster, but we do get economies of scale by centralizing the distribution services. Do you really think the Board would be willing to cut loose with some cash for that? Marshall: When they hired me, they assured me they would be willing to spend money on sustainability efforts. So even if it costs a bit more, they said they think it's an important enough issue to put some money behind it. But they are concerned about shareholders, so they need to know how much sales would have to go up to cover any additional costs. Jones: Sounds good. When would you need the information? Marshall: 'The Board wants me to prepare a cumulative report with recommendations from all the departments, so if we could get your results to me in one month, that would be great Jones: I don't know if I'll be able to make that deadline. I'm kind of swamped right now, and I'm not even sure what kind of analysis would be needed to determine the additional sales IMA EDUCATIONAL CASE JOURNAL VOL. 7, NO. 1, ART. 1, MARCH 2014 required to support the effort. Would there be money in the budget to hire a consulting team to check out the options? Marshall: As I said, the Board thinks this is an important issue, so I'm sure that isn't a problem. As long as you don't go overboard, go ahead and hire someone to do it. Jones: Will do. In the past, we always used a 10-year planning horizon, even though projects last longer than that. The Board generally thinks they can't forecast accurately past that. Is that the same for this project? Marshall I didn't know that was the policy, but it makes sense to me. That would be great, and I'll make sure the other department heads do the same. That will make it easier when I combine all the recommendations in my final report to the Board. After the meeting, Jones did some initial investigating and compiled some information regarding alternatives for this distribution center: 1. KPG could do nothing and continue using its existing distribution in Phoenix. If a new distribution center in the Central region were used, hopefully it could be available for use in January of the coming year. This new distribution center would save KPG 700,000 trucking miles per year. 2 KPG could build a new distribution center outside St. Louis in an area called Pontoon Beach. Looking online, it appeared the appropriate acreage could be purchased for $1 million 3. KPG could lease some space in a distribution center outside St. Louis in an area called Wood River. While researching this issue, Jones came across an article about Kraft Foods leasing warehouse space with an underground distribution center in Springfield, Mo. Because the facility is underground, it provides low-cost refrigeration. Jones even looked at some You Tube videos, mostly posted by truck drivers, , and it looked like this type of facility might work for KPG as well. This may have some additional sustainability advantages that Marshall and the Board might appreciate. Jones located another underground facility, Natural Chill, which is also outside St. Louis, and e-mailed the contact for more information about leasing that facility. Jones called your team to evaluate these four alternatives. You have a meeting in two weeks to discuss the alternatives and another meeting scheduled in six weeks to present your analysis. Figure 1 Major Markets and Distribution Centers o Proposed St. Louis Existing o Phoenix o o O Major Markets * Distribution Center BACKGROUND Chris Jones is the vice president of distribution for KPG Grocers, a large regional grocery store chain in the United States. The company started in Arizona, expanded throughout the West, and now has stores as far east as Indiana. The company recently hired Taylor Marshall in a newly created position of chief sustainability officer. Upon being hired, Marshall discussed sustainability with each major officer at KPG. The following is part of the discussion between Marshall and Jones. Marshall: As you know, sustainability has become an important issue today, and the Board has noticed that many of our competitors have been focusing on reducing their carbon footprint. In general, I've noticed KPG has been content just running the grocery business as usual. The Board, however, feels that to maintain our competitive advantage, as well as be a good corporate citizen, we should look at ways to become greener. Jones: We try to recycle and use those new light bulbs but really haven't thought about how distribution could address the issue. I'm just in charge of getting products from one place to the other. Our trucks are relatively new, so I don't really see how my department could help Marshall: Other retailers are finding they can reduce emissions, and maybe even save some money, by moving distribution centers closer to stores. As you can see from this map (see Figure 1), we currently use the distribution center in Phoenix, Ariz, to service stores as far away as Indiana, Minnesota, and Wisconsin, and we have plans to expand even further cast. I was wondering if it would be worthwhile to open a distribution center closer to those stores, perhaps in the St. Louis, Mo., area. Jones: Do you mean build a new distribution center? I always thought that might be a good idea just because we could increase freshness of produce and service those stores faster, but we do get economies of scale by centralizing the distribution services. Do you really think the Board would be willing to cut loose with some cash for that? Marshall: When they hired me, they assured me they would be willing to spend money on sustainability efforts. So even if it costs a bit more, they said they think it's an important enough issue to put some money behind it. But they are concerned about shareholders, so they need to know how much sales would have to go up to cover any additional costs. Jones: Sounds good. When would you need the information? Marshall: 'The Board wants me to prepare a cumulative report with recommendations from all the departments, so if we could get your results to me in one month, that would be great Jones: I don't know if I'll be able to make that deadline. I'm kind of swamped right now, and I'm not even sure what kind of analysis would be needed to determine the additional sales IMA EDUCATIONAL CASE JOURNAL VOL. 7, NO. 1, ART. 1, MARCH 2014 required to support the effort. Would there be money in the budget to hire a consulting team to check out the options? Marshall: As I said, the Board thinks this is an important issue, so I'm sure that isn't a problem. As long as you don't go overboard, go ahead and hire someone to do it. Jones: Will do. In the past, we always used a 10-year planning horizon, even though projects last longer than that. The Board generally thinks they can't forecast accurately past that. Is that the same for this project? Marshall I didn't know that was the policy, but it makes sense to me. That would be great, and I'll make sure the other department heads do the same. That will make it easier when I combine all the recommendations in my final report to the Board. After the meeting, Jones did some initial investigating and compiled some information regarding alternatives for this distribution center: 1. KPG could do nothing and continue using its existing distribution in Phoenix. If a new distribution center in the Central region were used, hopefully it could be available for use in January of the coming year. This new distribution center would save KPG 700,000 trucking miles per year. 2 KPG could build a new distribution center outside St. Louis in an area called Pontoon Beach. Looking online, it appeared the appropriate acreage could be purchased for $1 million 3. KPG could lease some space in a distribution center outside St. Louis in an area called Wood River. While researching this issue, Jones came across an article about Kraft Foods leasing warehouse space with an underground distribution center in Springfield, Mo. Because the facility is underground, it provides low-cost refrigeration. Jones even looked at some You Tube videos, mostly posted by truck drivers, , and it looked like this type of facility might work for KPG as well. This may have some additional sustainability advantages that Marshall and the Board might appreciate. Jones located another underground facility, Natural Chill, which is also outside St. Louis, and e-mailed the contact for more information about leasing that facility. Jones called your team to evaluate these four alternatives. You have a meeting in two weeks to discuss the alternatives and another meeting scheduled in six weeks to present your analysis. Figure 1 Major Markets and Distribution Centers o Proposed St. Louis Existing o Phoenix o o O Major Markets * Distribution Center

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts