Question: Show all steps to get full score. The table below gives the manufacturing process flow of producing a face shield using 3D printing. Assuming the

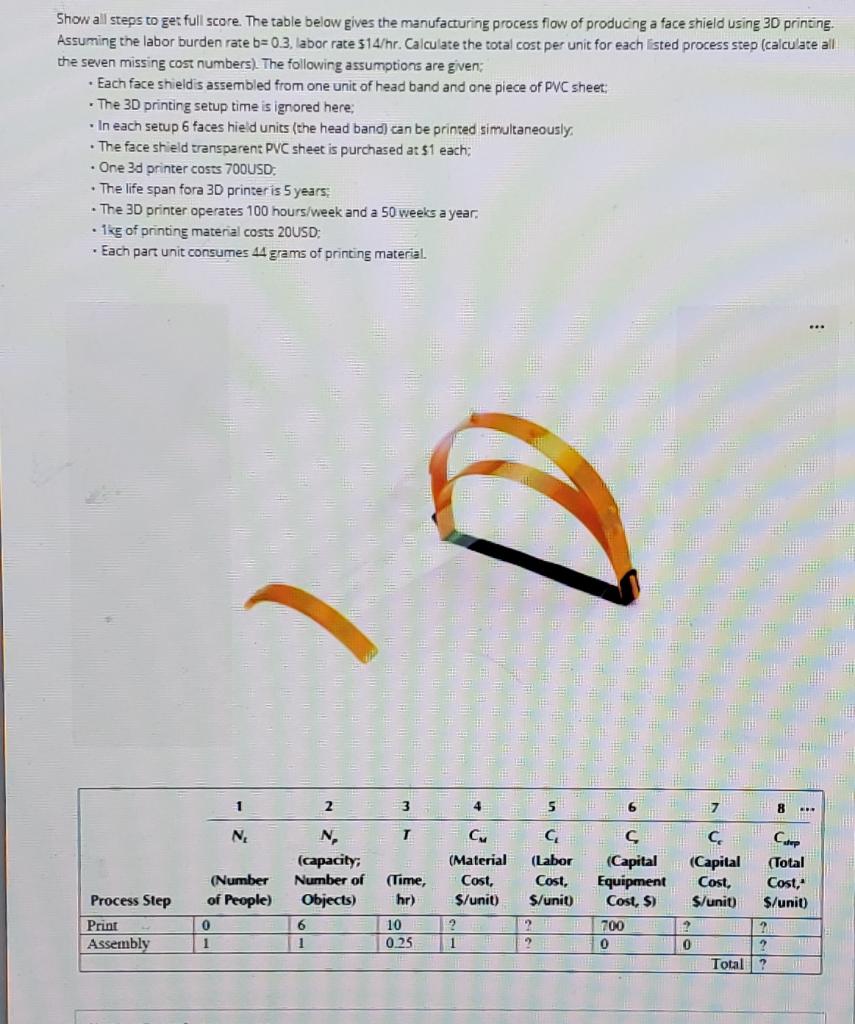

Show all steps to get full score. The table below gives the manufacturing process flow of producing a face shield using 3D printing. Assuming the labor burden rate b=0.3, labor rate $14/hr. Calculate the total cost per unit for each listed process step (calculate all the seven missing cost numbers). The following assumptions are given Each face shieldis assembled from one unit of head band and one piece of PVC sheet The 3D printing setup time is ignored here: In each setup 6 faces hield units (the head band) can be printed simultaneously . The face shield transparent PVC sheet is purchased at $1 each: One 3d printer costs 700USD The life span fora 3D printer is 5 years The 3D printer operates 100 hours/week and a 50 weeks a year. 1kg of printing material costs 20USD: Each part unit consumes 44 grams of printing material. 1 2 3 4 5 6 7 8 N, T N, (capacity, Number of Objects) 6 1 CM (Material Cost, $/unit) C (Labor Cost, $/unit) (Capital Equipment Cost, $) (Time, hr) (Capital Cost, $/unit) Chep (Total Cost, $/unit) (Number of People) 0 1 Process Step Print Assembly 2 2 10 0.25 2 1 700 0 22 0 2 Total

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts