Question: SHOW ALL WORK PLEASE 1. You are a purchaser and a quality management expert. A manufacturer of different automobile products received an order to supply

SHOW ALL WORK PLEASE

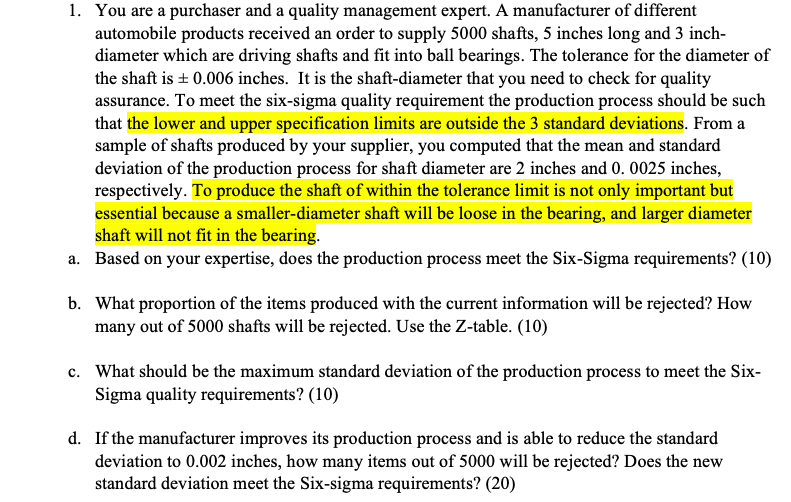

1. You are a purchaser and a quality management expert. A manufacturer of different automobile products received an order to supply 5000 shafts, 5 inches long and 3 inch- diameter which are driving shafts and fit into ball bearings. The tolerance for the diameter of the shaft is = 0.006 inches. It is the shaft-diameter that you need to check for quality assurance. To meet the six-sigma quality requirement the production process should be such that the lower and upper specification limits are outside the 3 standard deviations. From a sample of shafts produced by your supplier, you computed that the mean and standard deviation of the production process for shaft diameter are 2 inches and 0.0025 inches, respectively. To produce the shaft of within the tolerance limit is not only important but essential because a smaller-diameter shaft will be loose in the bearing, and larger diameter shaft will not fit in the bearing. a. Based on your expertise, does the production process meet the Six-Sigma requirements? (10) b. What proportion of the items produced with the current information will be rejected? How many out of 5000 shafts will be rejected. Use the Z-table. (10) c. What should be the maximum standard deviation of the production process to meet the Six- Sigma quality requirements? (10) d. If the manufacturer improves its production process and is able to reduce the standard deviation to 0.002 inches, how many items out of 5000 will be rejected? Does the new standard deviation meet the Six-sigma requirements? (20)Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock