Question: show steps please a) Draw a schematic diagram for the process. b) What should the workstation cycle time be in the assembly line in order

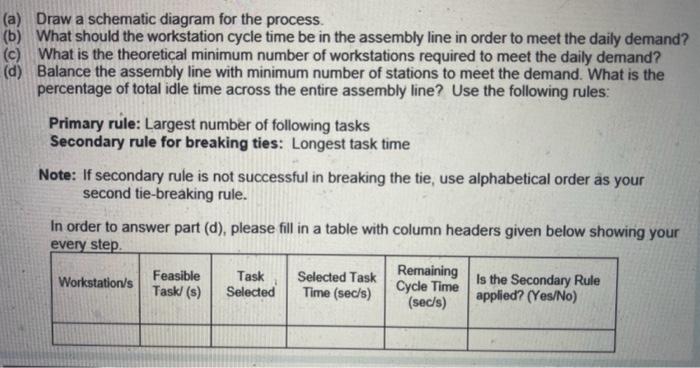

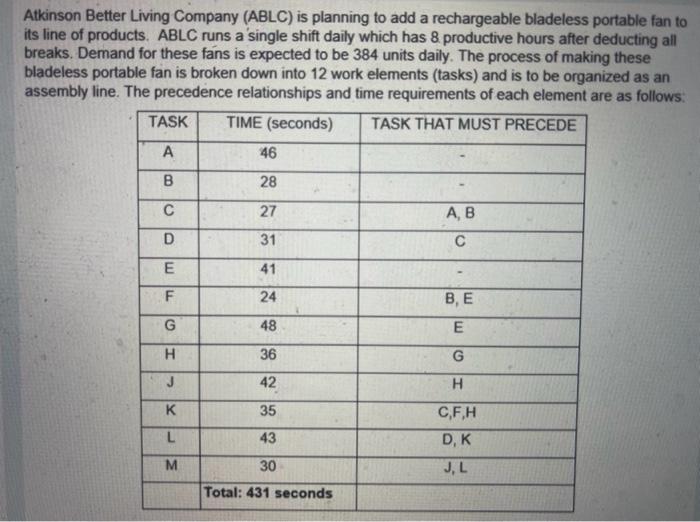

a) Draw a schematic diagram for the process. b) What should the workstation cycle time be in the assembly line in order to meet the daily demand? c) What is the theoretical minimum number of workstations required to meet the daily demand? d) Balance the assembly line with minimum number of stations to meet the demand. What is the percentage of total idle time across the entire assembly line? Use the following rules: Primary rule: Largest number of following tasks Secondary rule for breaking ties: Longest task time Note: If secondary rule is not successful in breaking the tie, use alphabetical order as your second tie-breaking rule. In order to answer part (d), please fill in a table with column headers given below showing your Atkinson Better Living Company (ABLC) is planning to add a rechargeable bladeless portable fan to its line of products. ABLC runs a single shift daily which has 8 productive hours after deducting all breaks. Demand for these fans is expected to be 384 units daily. The process of making these bladeless portable fan is broken down into 12 work elements (tasks) and is to be organized as an assembly line. The precedence relationships and time requirements of each element are as follows

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts