Question: show work A batch of material must visit 4 workstations in a series to be converted to product. Each batch has a size of 10

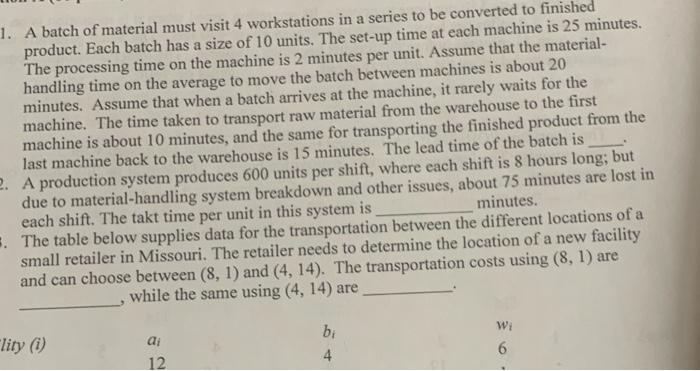

A batch of material must visit 4 workstations in a series to be converted to product. Each batch has a size of 10 units. The set-up time at each machine is 25 minutes. The processing time on the machine is 2 minutes per unit. Assume that the materialhandling time on the average to move the batch between machines is about 20 minutes. Assume that when a batch arrives at the machine, it rarely waits for the machine. The time taken to transport raw material from the warehouse to the first machine is about 10 minutes, and the same for transporting the finished product from the last machine back to the warehouse is 15 minutes. The lead time of the batch is A production system produces 600 units per shift, where each shift is 8 hours long; but due to material-handling system breakdown and other issues, about 75 minutes are lost in each shift. The takt time per unit in this system is minutes. The table below supplies data for the transportation between the different locations of a small retailer in Missouri. The retailer needs to determine the location of a new facility and can choose between (8,1) and (4,14). The transportation costs using (8,1) are , while the same using (4,14) are A batch of material must visit 4 workstations in a series to be converted to product. Each batch has a size of 10 units. The set-up time at each machine is 25 minutes. The processing time on the machine is 2 minutes per unit. Assume that the materialhandling time on the average to move the batch between machines is about 20 minutes. Assume that when a batch arrives at the machine, it rarely waits for the machine. The time taken to transport raw material from the warehouse to the first machine is about 10 minutes, and the same for transporting the finished product from the last machine back to the warehouse is 15 minutes. The lead time of the batch is A production system produces 600 units per shift, where each shift is 8 hours long; but due to material-handling system breakdown and other issues, about 75 minutes are lost in each shift. The takt time per unit in this system is minutes. The table below supplies data for the transportation between the different locations of a small retailer in Missouri. The retailer needs to determine the location of a new facility and can choose between (8,1) and (4,14). The transportation costs using (8,1) are , while the same using (4,14) are

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts