Question: Simulating a Push and Pull Production Process Consider a production system with two stations, Station 1 feeds Station 2 and Station 2 observes customer demand.

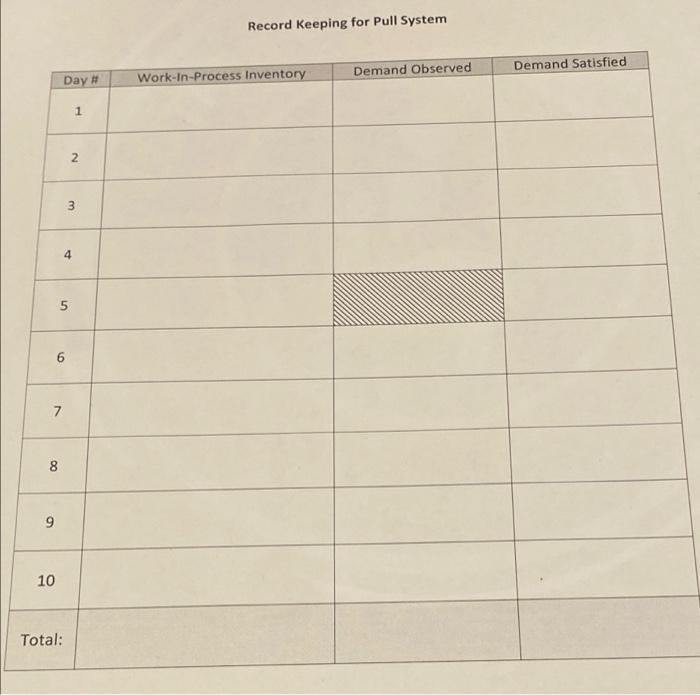

Simulating a Push and Pull Production Process Consider a production system with two stations, Station 1 feeds Station 2 and Station 2 observes customer demand. The daily customer demand can be 2, 4 or 6; each with probability. Note that expected daily demand is 4 (2 + 4 + 6 = 4). Station 1 Station 2 Station 1 can feed Station 2 in two different ways: One possible strategy could be to feed (or "push") four items (as much as the expected demand) to Station 2 at the start of every day. Si is not interested in what S2 is going through and there is no information sharing or flow between 51 and 52. This is a typical Push system. Another possible strategy could be to locate two bins between S1 and 52. Each bin holds three items. Whenever at least one of the bins is empty, a flag is raised to trigger production in S1. Si will produce only if a flag is up and fill the empty bin(s). This is a typical Pull system. In each group, one of you will act as Station 1 (S1), one of you will act as Station 2 (S2), and one or two of you will be record keeper (RK) and fill out the forms to keep track of the satisfied and lost demand and work-in-process inventory. Pull System: Simulate a pull production system as follows: 1. s2 will generate a random number between 1 and 3 and observe the demand, Das follows: (2 if random number is 1 D = 4 if random number is 2 16 if random number is 3 S2 will draw D items from the work-in-process inventory bin. If at least one of the bins is empty, S2 puts the flag up. 2. If the flag is up, Si fills up the empty bins. S2 does not observe demand on Day 5 because the operator is sick and absent (or the machine is not working). S1 does not know this and produces if the flag is up to fill the empty bins as usual. Record keeping for Pull System Demand Observed Demand Satisfied Day # Work-In-Process Inventory 1 2 2. 3 4 5 6 7 8 9 10 Total: Simulating a Push and Pull Production Process Consider a production system with two stations, Station 1 feeds Station 2 and Station 2 observes customer demand. The daily customer demand can be 2, 4 or 6; each with probability. Note that expected daily demand is 4 (2 + 4 + 6 = 4). Station 1 Station 2 Station 1 can feed Station 2 in two different ways: One possible strategy could be to feed (or "push") four items (as much as the expected demand) to Station 2 at the start of every day. Si is not interested in what S2 is going through and there is no information sharing or flow between 51 and 52. This is a typical Push system. Another possible strategy could be to locate two bins between S1 and 52. Each bin holds three items. Whenever at least one of the bins is empty, a flag is raised to trigger production in S1. Si will produce only if a flag is up and fill the empty bin(s). This is a typical Pull system. In each group, one of you will act as Station 1 (S1), one of you will act as Station 2 (S2), and one or two of you will be record keeper (RK) and fill out the forms to keep track of the satisfied and lost demand and work-in-process inventory. Pull System: Simulate a pull production system as follows: 1. s2 will generate a random number between 1 and 3 and observe the demand, Das follows: (2 if random number is 1 D = 4 if random number is 2 16 if random number is 3 S2 will draw D items from the work-in-process inventory bin. If at least one of the bins is empty, S2 puts the flag up. 2. If the flag is up, Si fills up the empty bins. S2 does not observe demand on Day 5 because the operator is sick and absent (or the machine is not working). S1 does not know this and produces if the flag is up to fill the empty bins as usual. Record keeping for Pull System Demand Observed Demand Satisfied Day # Work-In-Process Inventory 1 2 2. 3 4 5 6 7 8 9 10 Total