Question: SKILL DEVELOPMENT STUDY # 2 Due date: December 2 2 , 2 0 2 4 Material Specification for a Pressurized Cylindrical Tank Consider a thin

SKILL DEVELOPMENT STUDY #

Due date: December

Material Specification for a Pressurized Cylindrical Tank

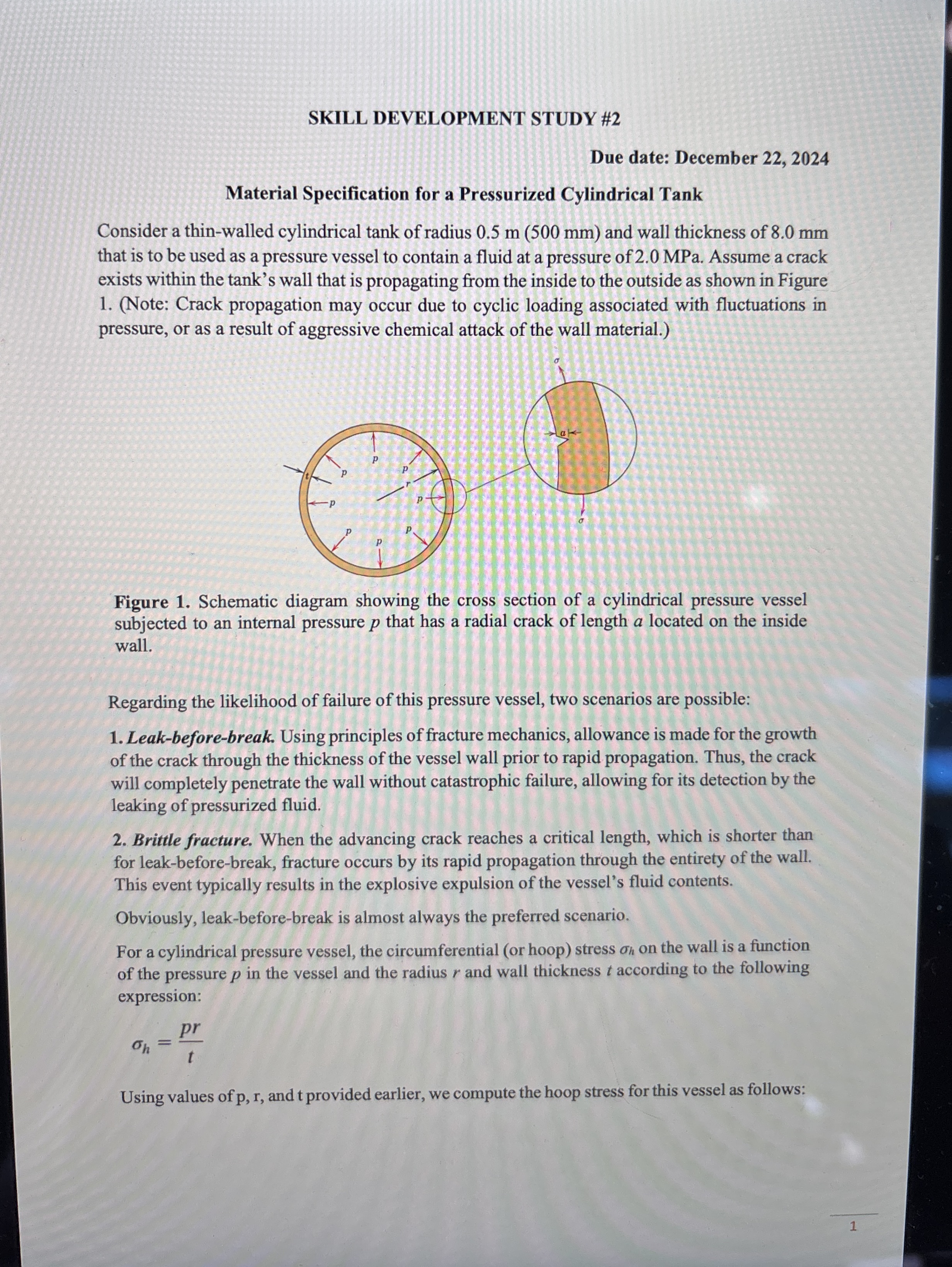

Consider a thinwalled cylindrical tank of radius and wall thickness of mm that is to be used as a pressure vessel to contain a fluid at a pressure of MPa Assume a crack exists within the tanks wall that is propagating from the inside to the outside as shown in Figure Note: Crack propagation may occur due to cyclic loading associated with fluctuations in pressure, or as a result of aggressive chemical attack of the wall material.

Figure Schematic diagram showing the cross section of a cylindrical pressure vessel subjected to an internal pressure that has a radial crack of length a located on the inside wall.

Regarding the likelihood of failure of this pressure vessel, two scenarios are possible:

Leakbeforebreak. Using principles of fracture mechanics, allowance is made for the growth of the crack through the thickness of the vessel wall prior to rapid propagation. Thus, the crack will completely penetrate the wall without catastrophic failure, allowing for its detection by the leaking of pressurized fluid.

Brittle fracture. When the advancing crack reaches a critical length, which is shorter than for leakbeforebreak, fracture occurs by its rapid propagation through the entirety of the wall. This event typically results in the explosive expulsion of the vessel's fluid contents.

Obviously, leakbeforebreak is almost always the preferred scenario.

For a cylindrical pressure vessel, the circumferential or hoop stress on the wall is a function of the pressure in the vessel and the radius and wall thickness according to the following expression:

Using values of and t provided earlier, we compute the hoop stress for this vessel as follows:

SKILL DEVELOPMENT STUDY #

Due date: December

Material Specification for a Pressurized Cylindrical Tank

Consider a thinwalled cylindrical tank of radius and wall thickness of mm that is to be used as a pressure vessel to contain a fluid at a pressure of MPa Assume a crack exists within the tanks wall that is propagating from the inside to the outside as shown in Figure Note: Crack propagation may occur due to cyclic loading associated with fluctuations in pressure, or as a result of aggressive chemical attack of the wall material.

Figure Schematic diagram showing the cross section of a cylindrical pressure vessel subjected to an internal pressure that has a radial crack of length a located on the inside wall.

Regarding the likelihood of failure of this pressure vessel, two scenarios are possible:

Leakbeforebreak. Using principles of fracture mechanics, allowance is made for the growth of the crack through the thickness of the vessel wall prior to rapid propagation. Thus, the crack will completely penetrate the wall without catastrophic failure, allowing for its detection by the leaking of pressurized fluid.

Brittle fracture. When the advancing crack reaches a critical length, which is shorter than for leakbeforebreak, fracture occurs by its rapid propagation through the entirety of the wall. This event typically results in the explosive expulsion of the vessel's fluid contents.

Obviously, leakbeforebreak is almost always the preferred scenario.

For a cylindrical pressure vessel, the circumferential or hoop stress on the wall is a function of the pressure in the vessel and the radius and wall thickness according to the following expression:

Using values of and t provided earlier, we compute the hoop stress for this vessel as follows:

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock