Question: Smart Widget Inc. ( SWI ) manufactures and distributes precision systems for pharmaceutical production lines, touchscreen displays, hospital needs and other gadgets. Answer the following

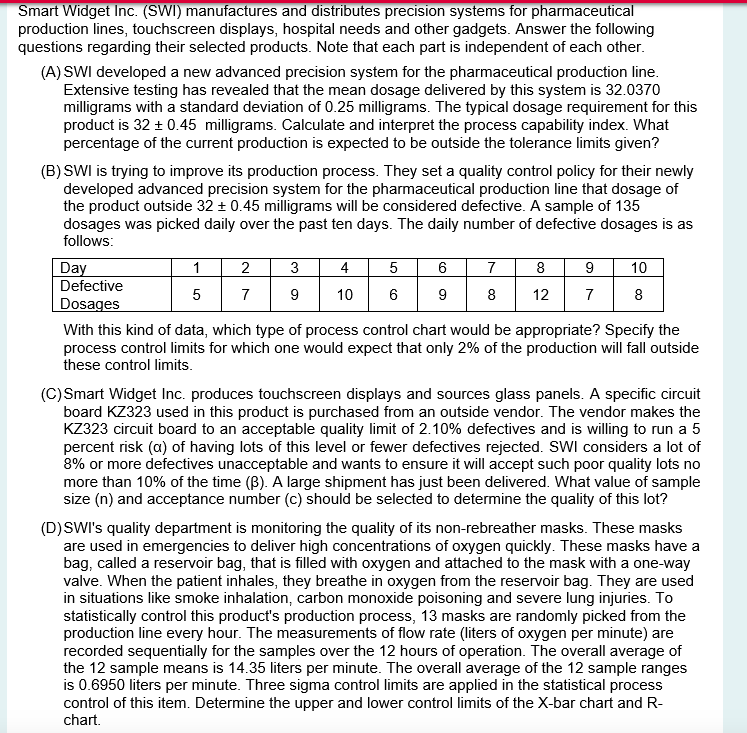

Smart Widget Inc. SWI manufactures and distributes precision systems for pharmaceutical production lines, touchscreen displays, hospital needs and other gadgets. Answer the following questions regarding their selected products. Note that each part is independent of each other.

A SWI developed a new advanced precision system for the pharmaceutical production line. Extensive testing has revealed that the mean dosage delivered by this system is milligrams with a standard deviation of milligrams. The typical dosage requirement for this product is pm milligrams. Calculate and interpret the process capability index. What percentage of the current production is expected to be outside the tolerance limits given?

B SWI is trying to improve its production process. They set a quality control policy for their newly developed advanced precision system for the pharmaceutical production line that dosage of the product outside pm milligrams will be considered defective. A sample of dosages was picked daily over the past ten days. The daily number of defective dosages is as follows:

With this kind of data, which type of process control chart would be appropriate? Specify the process control limits for which one would expect that only of the production will fall outside these control limits

C Smart Widget Inc. produces touchscreen displays and sources glass panels. A specific circuit board KZ used in this product is purchased from an outside vendor. The vendor makes the KZ circuit board to an acceptable quality limit of defectives and is willing to run a percent risk alpha of having lots of this level or fewer defectives rejected. SWI considers a lot of or more defectives unacceptable and wants to ensure it will accept such poor quality lots no more than of the time beta A large shipment has just been delivered. What value of sample size n and acceptance number c should be selected to determine the quality of this lot?

D SWI's quality department is monitoring the quality of its nonrebreather masks. These masks are used in emergencies to deliver high concentrations of oxygen quickly. These masks have a bag, called a reservoir bag, that is filled with oxygen and attached to the mask with a oneway valve. When the patient inhales, they breathe in oxygen from the reservoir bag. They are used in situations like smoke inhalation, carbon monoxide poisoning and severe lung injuries. To statistically control this product's production process, masks are randomly picked from the production line every hour. The measurements of flow rate liters of oxygen per minute are recorded sequentially for the samples over the hours of operation. The overall average of the sample means is liters per minute. The overall average of the sample ranges is liters per minute. Three sigma control limits are applied in the statistical process control of this item. Determine the upper and lower control limits of the Xbar chart and Rchart.

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock