Question: solve it quickly please 10. We plan to remove methylcyclohexane from n-heptane using aniline as the solvent (see Table 14-4 for equilibrium data). The feed

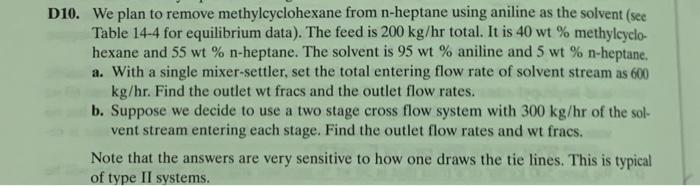

10. We plan to remove methylcyclohexane from n-heptane using aniline as the solvent (see Table 14-4 for equilibrium data). The feed is 200kg/hr total. It is 40wt% methylcyclohexane and 55wt%n-heptane. The solvent is 95wt% aniline and 5wt%n-heptane. a. With a single mixer-settler, set the total entering flow rate of solvent stream as 600 kg/hr. Find the outlet wt fracs and the outlet flow rates. b. Suppose we decide to use a two stage cross flow system with 300kg/hr of the solvent stream entering each stage. Find the outlet flow rates and wt fracs. Note that the answers are very sensitive to how one draws the tie lines. This is typical of type II systems. 10. We plan to remove methylcyclohexane from n-heptane using aniline as the solvent (see Table 14-4 for equilibrium data). The feed is 200kg/hr total. It is 40wt% methylcyclohexane and 55wt%n-heptane. The solvent is 95wt% aniline and 5wt%n-heptane. a. With a single mixer-settler, set the total entering flow rate of solvent stream as 600 kg/hr. Find the outlet wt fracs and the outlet flow rates. b. Suppose we decide to use a two stage cross flow system with 300kg/hr of the solvent stream entering each stage. Find the outlet flow rates and wt fracs. Note that the answers are very sensitive to how one draws the tie lines. This is typical of type II systems

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts