Question: solver Livermore Manufacturing assembles some equipment used in Amazon distribution centers. One product is called Runningmaster. The assembly of the Runningmaster is made up of

solver

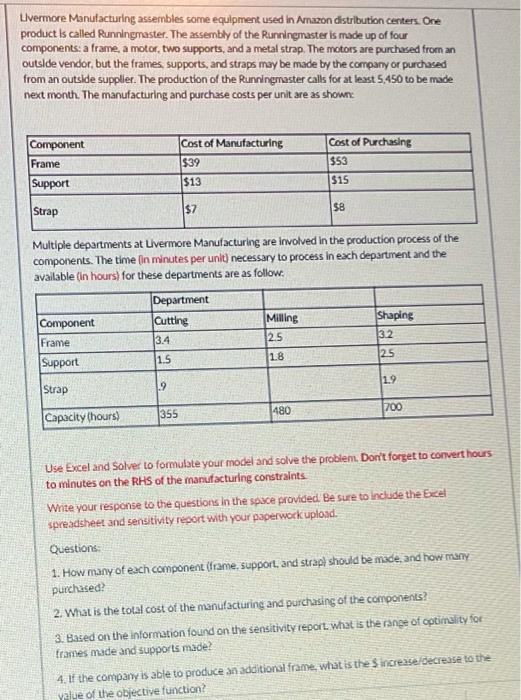

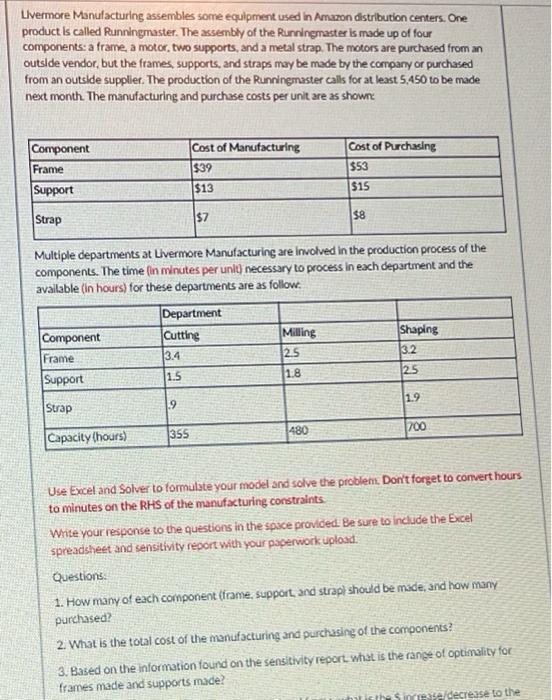

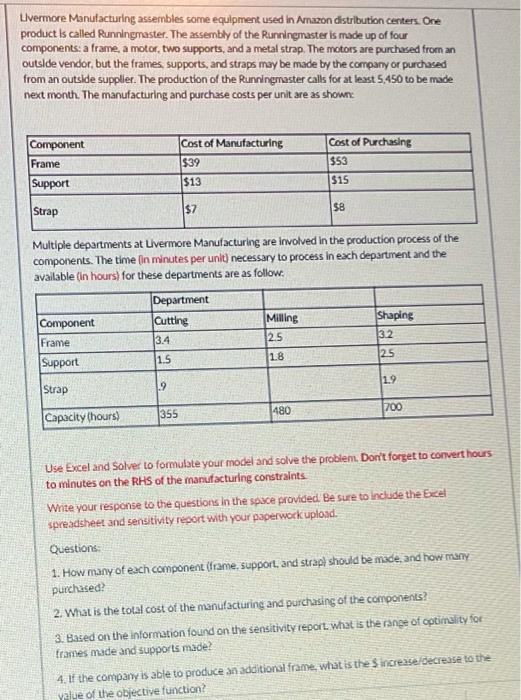

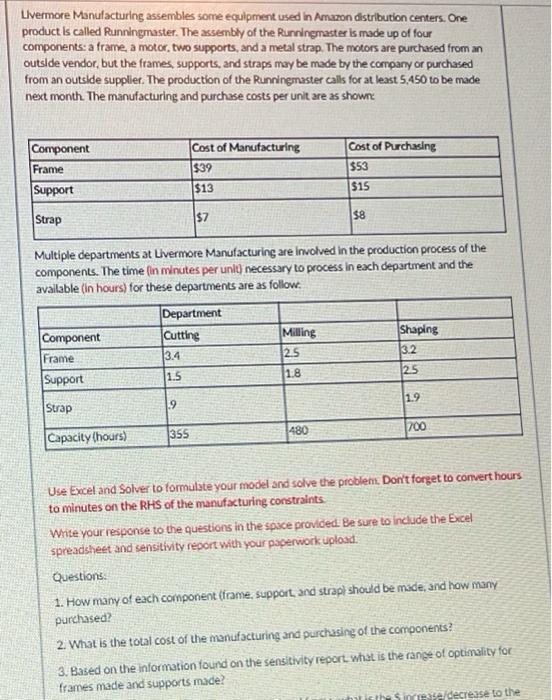

Livermore Manufacturing assembles some equipment used in Amazon distribution centers. One product is called Runningmaster. The assembly of the Runningmaster is made up of four components: a frame, a motor, two supports, and a metal strap. The motors are purchased from an outside vendor, but the frames supports, and straps may be made by the company or purchased from an outside suppler. The production of the Runningmaster calls for at least 5,450 to be made next month. The manufacturing and purchase costs per unit are as shown Component Frame Support Cost of Manufacturing $39 $13 Cost of Purchasing $53 $15 Strap $7 $8 Multiple departments at Livermore Manufacturing are involved in the production process of the components. The time in minutes per unit) necessary to process in each department and the available (in hours) for these departments are as follow. Department Component Cutting Milling Shaping Frame 3.4 25 Support 1.5 1.8 25 32 19 Strap 9 1480 700 355 Capacity (hours) Use Excel and Solver to fomulate your model and solve the problent. Don't forget to convert hours to minutes on the RHS of the manufacturing constraints Write your response to the questions in the space provided. Be sure to include the Excel spreadsheet and sensitivity report with your paperwork upload. Questions 1. How many of each component drame, support, and strap) should be made, and how many purchased 2. What is the total cost of the manufacturing and purchasing of the components? 3. Based on the information found on the sensitivity report what is the range of optimality for frames made and supports made? 4. If the company is able to produce an additional frame. what is the increase/decrease to the Yalue of the objective function? Livermore Manufacturing assembles some equipment used in Amazon distribution centers. One product is called Runningmaster. The assesnbly of the Runningmaster is made up of four components: a frame, a motor, two supports, and a metal strap. The motors are purchased from an outside vendor, but the frames, supports, and straps may be made by the company or purchased from an outside supplier. The production of the Runningmaster calls for at least 5,450 to be made next month. The manufacturing and purchase costs per unit are as shown Component Frame Support Cost of Manufacturing $39 Cost of Purchasing $53 $15 $13 Strap $7 $8 Multiple departments at Livermore Manufacturing are involved in the production process of the components. The time in minutes per unlu) necessary to process in each department and the available (In hours) for these departments are as follow. Department Component Cutting Milling Shaping Frame 13.4 2.5 32 Support 1.5 1.8 25 19 Strap 1.9 480 700 355 Capacity (hours) Use Excel and Solver to formulate your model and solve the problemi. Don't forget to convert hours to minutes on the RHS of the manufacturing constraints Write your response to the questions in the spice provided Be sure to include the Excel spreadsheet and sensitivity report with your paperwork upload. Questions 1. How many of each component (frame, support, and strap should be made, and how many purchased? 2. What is the total cost of the manufacturing and purchasing of the components? 3. Based on the information found on the sensitivity report what is the range of optimality for frames made and supports made? Se decrease to the

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock