Question: Someone please help REPLENISHMENT & SAFETY STOCK STUDY CASE Consider the following scenario: The Supply Manager in a widget manufacturing company operating in a Make-To-Stock

Someone please help

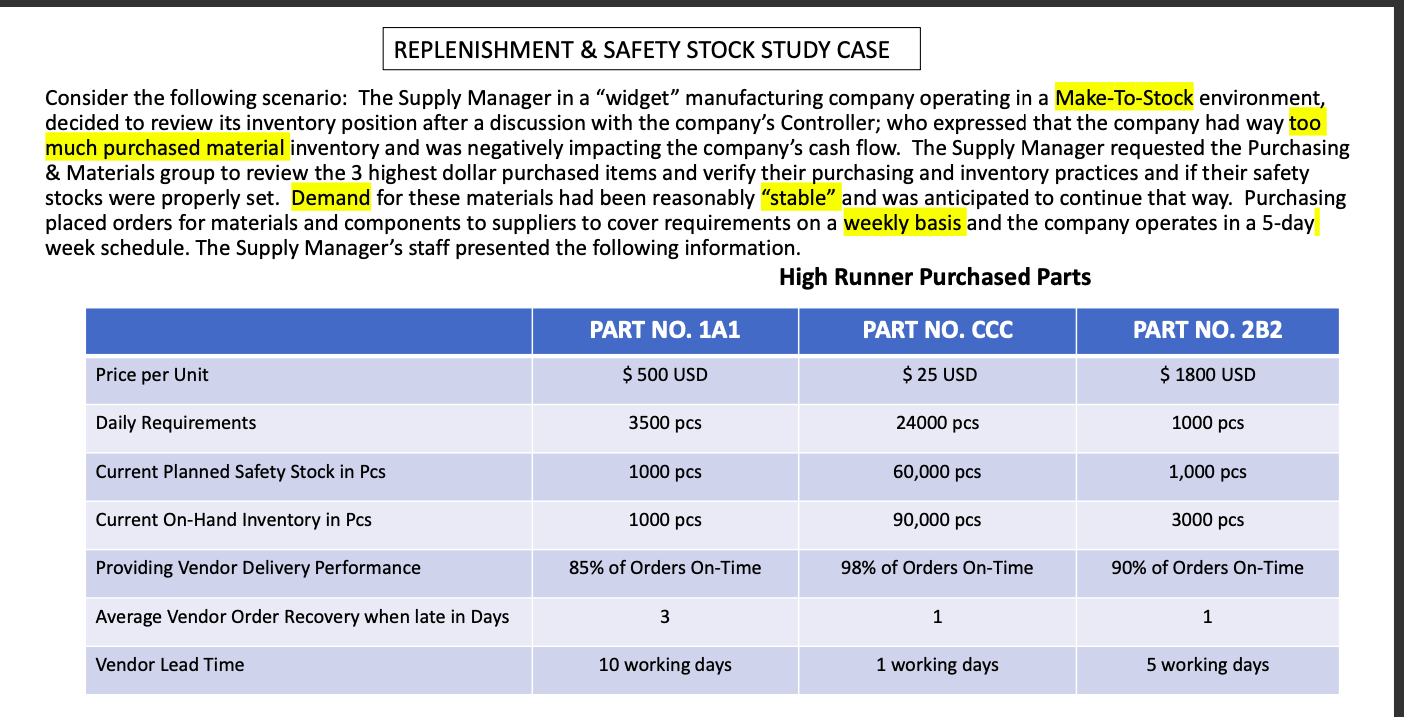

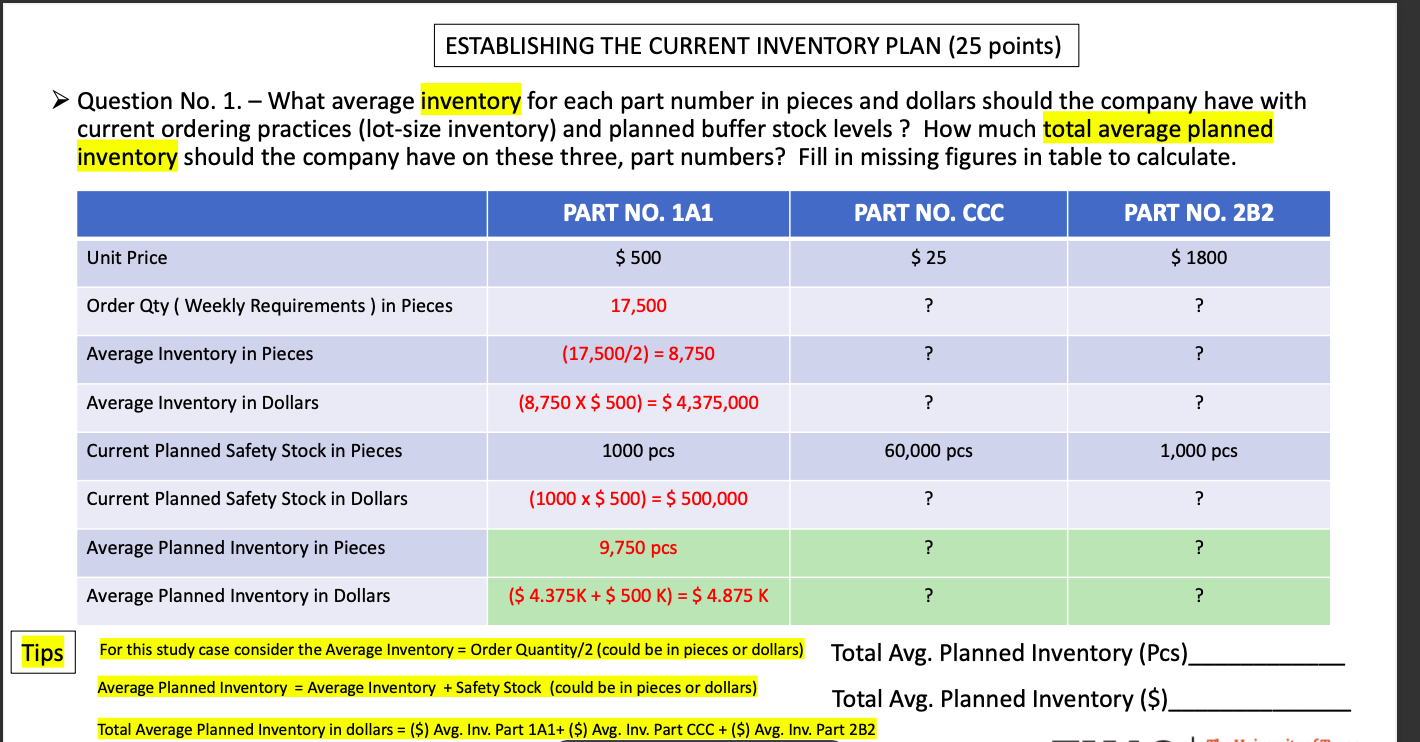

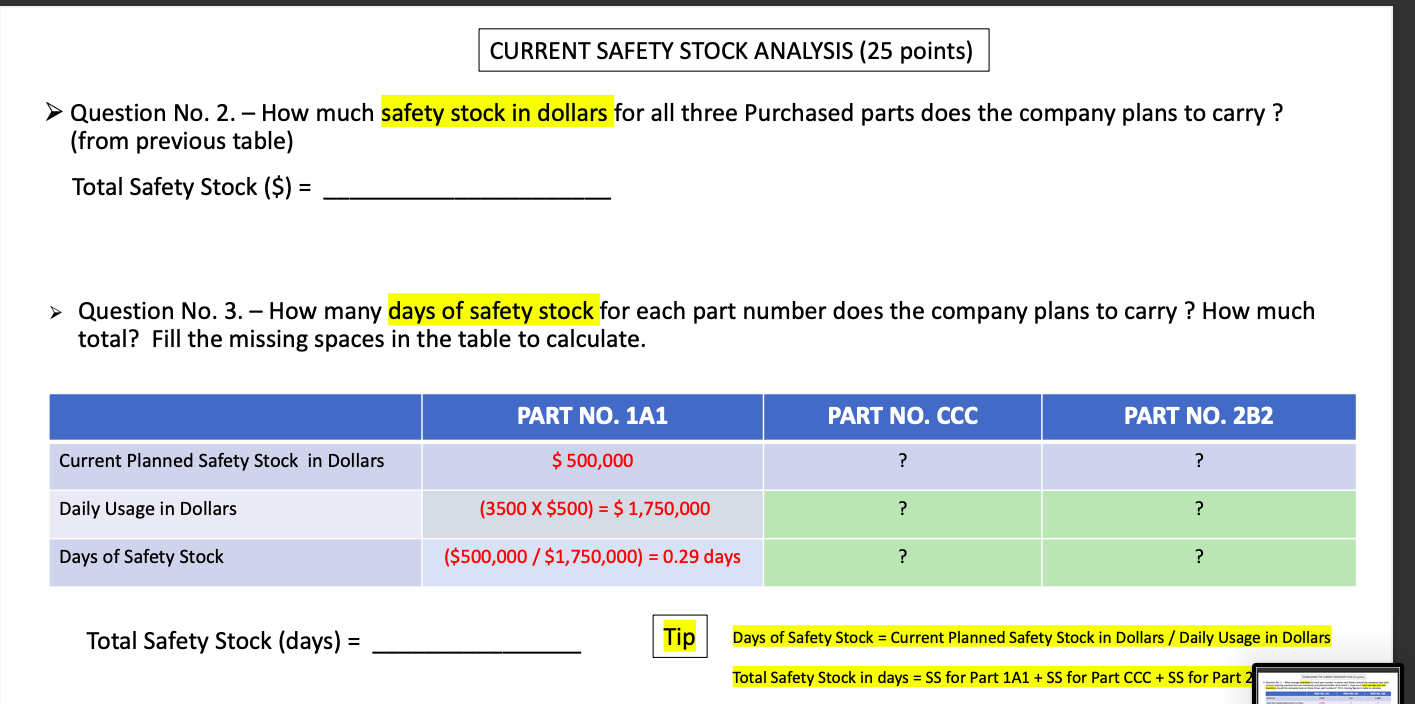

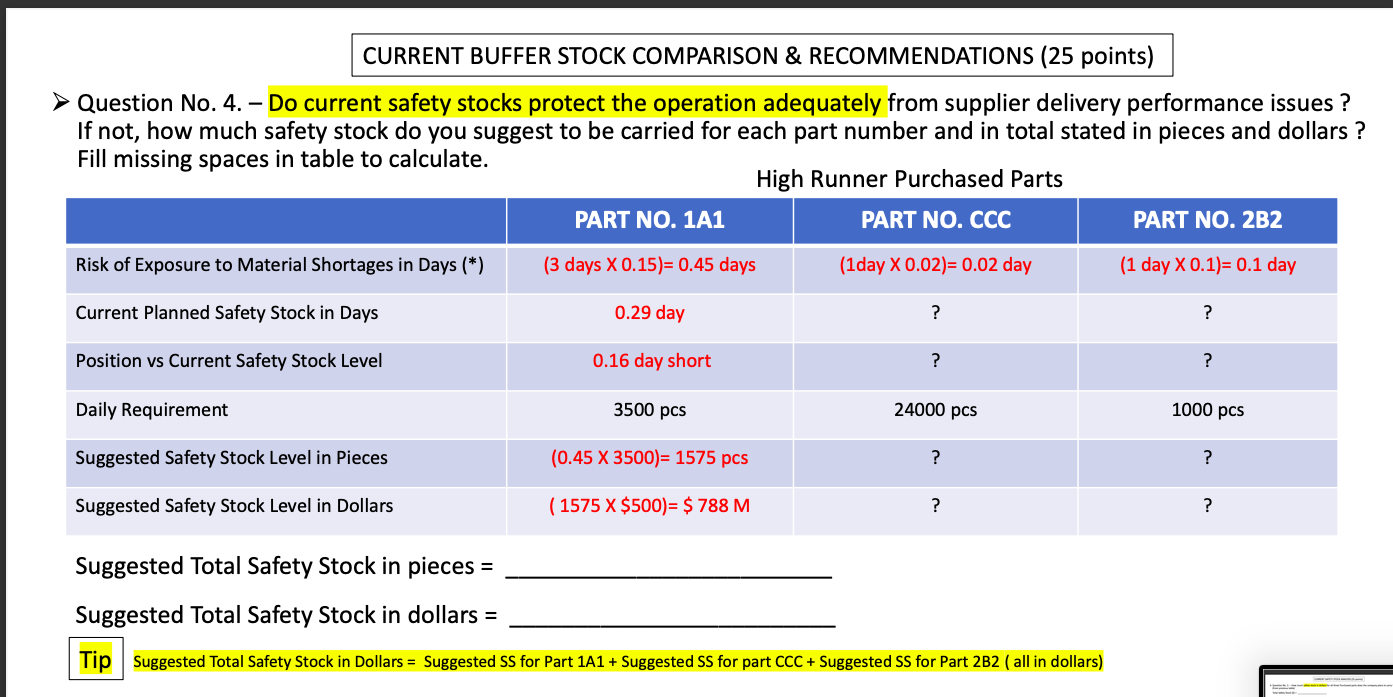

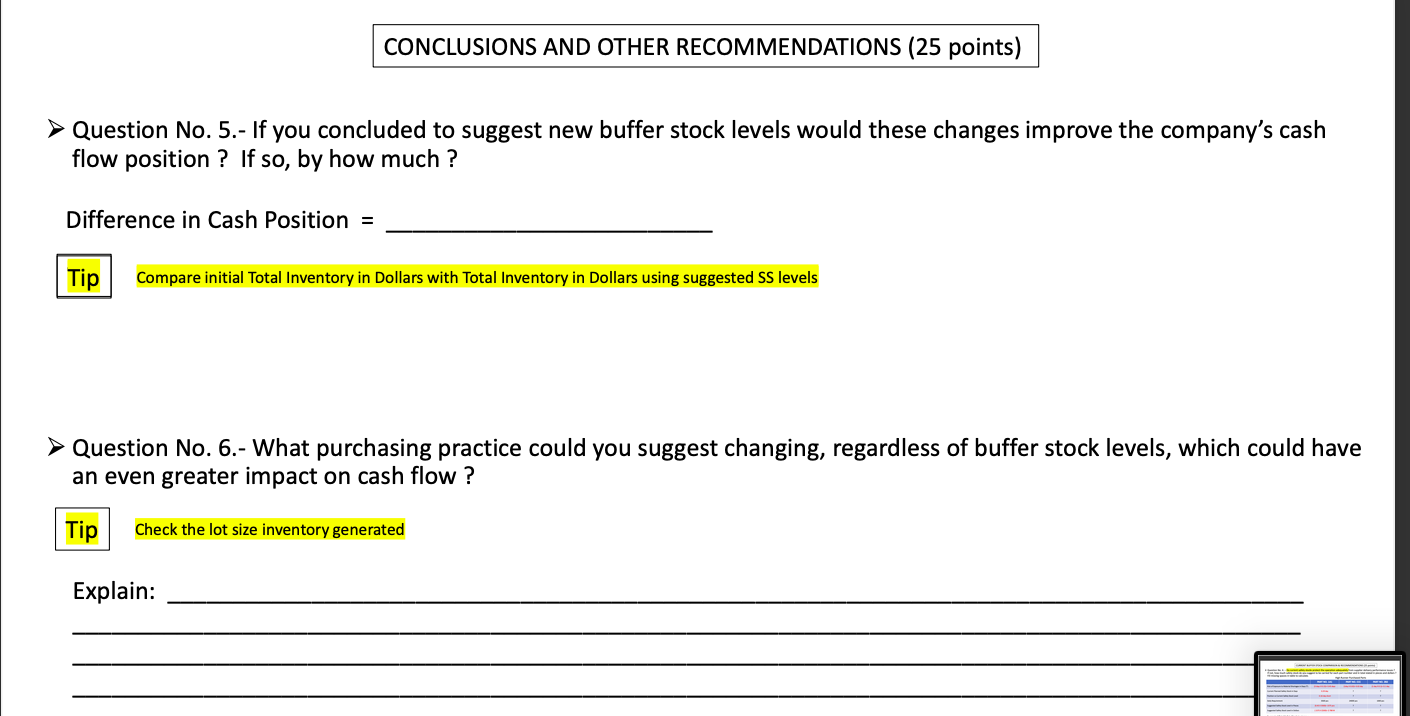

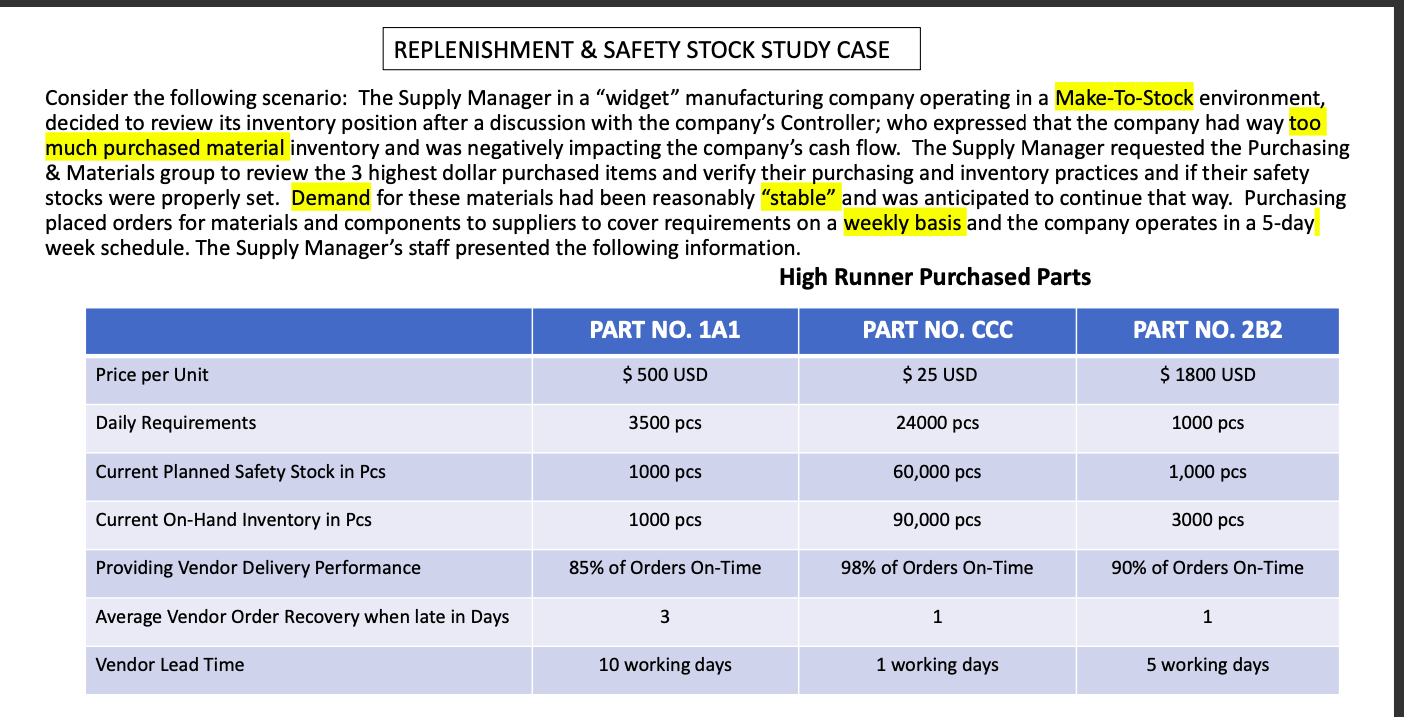

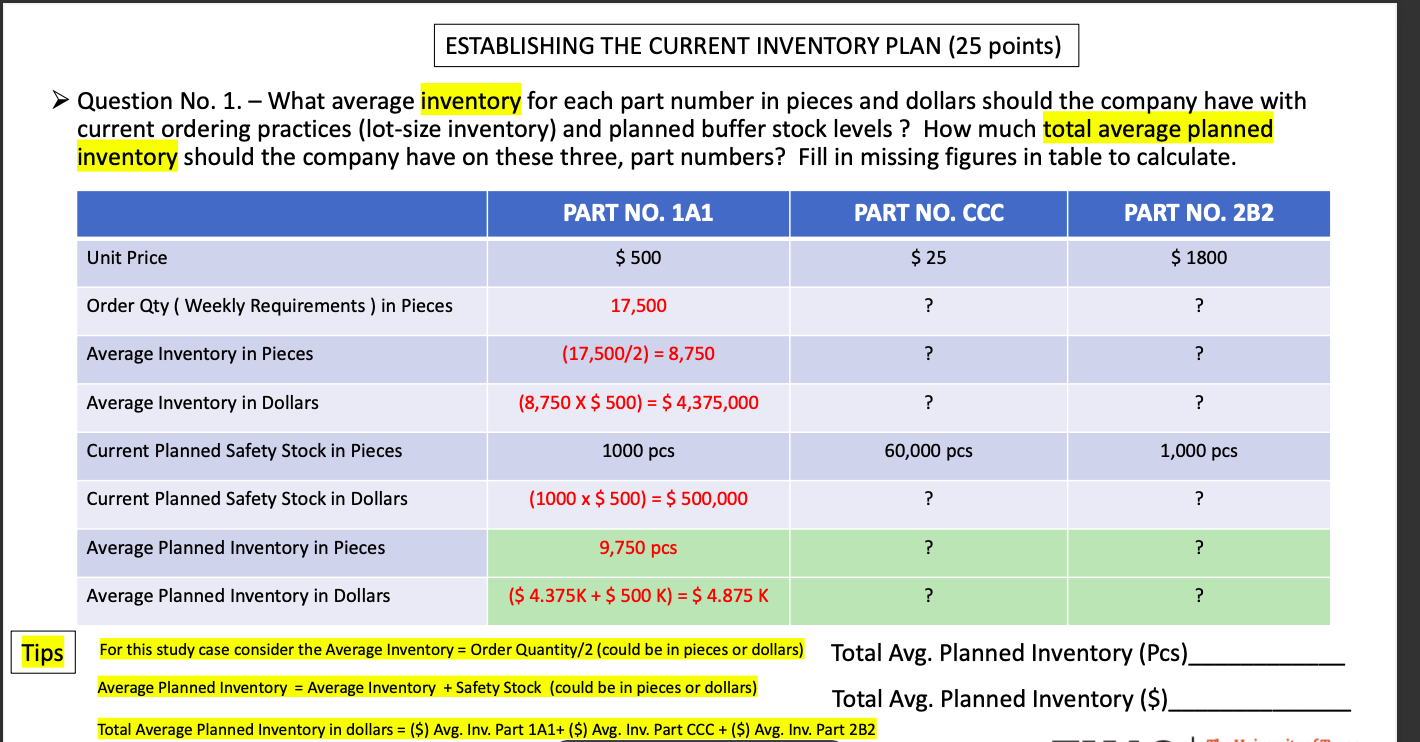

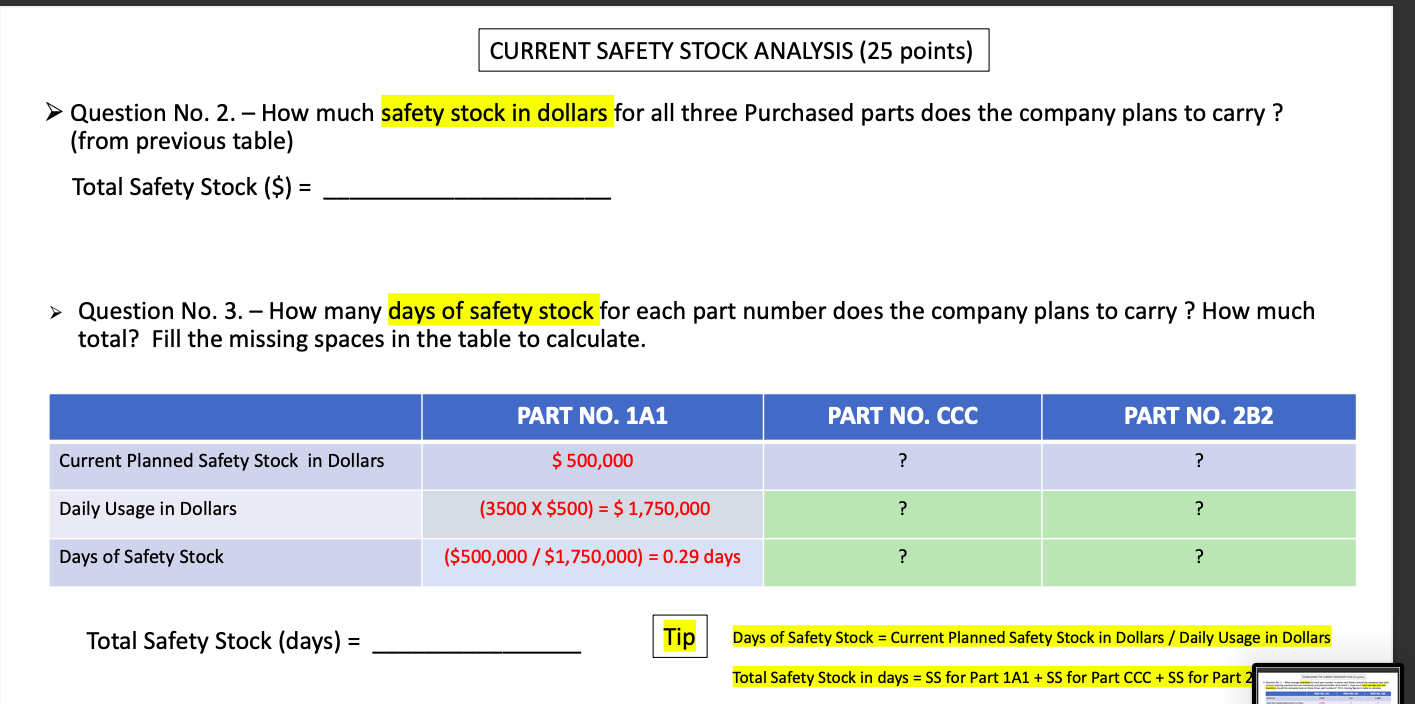

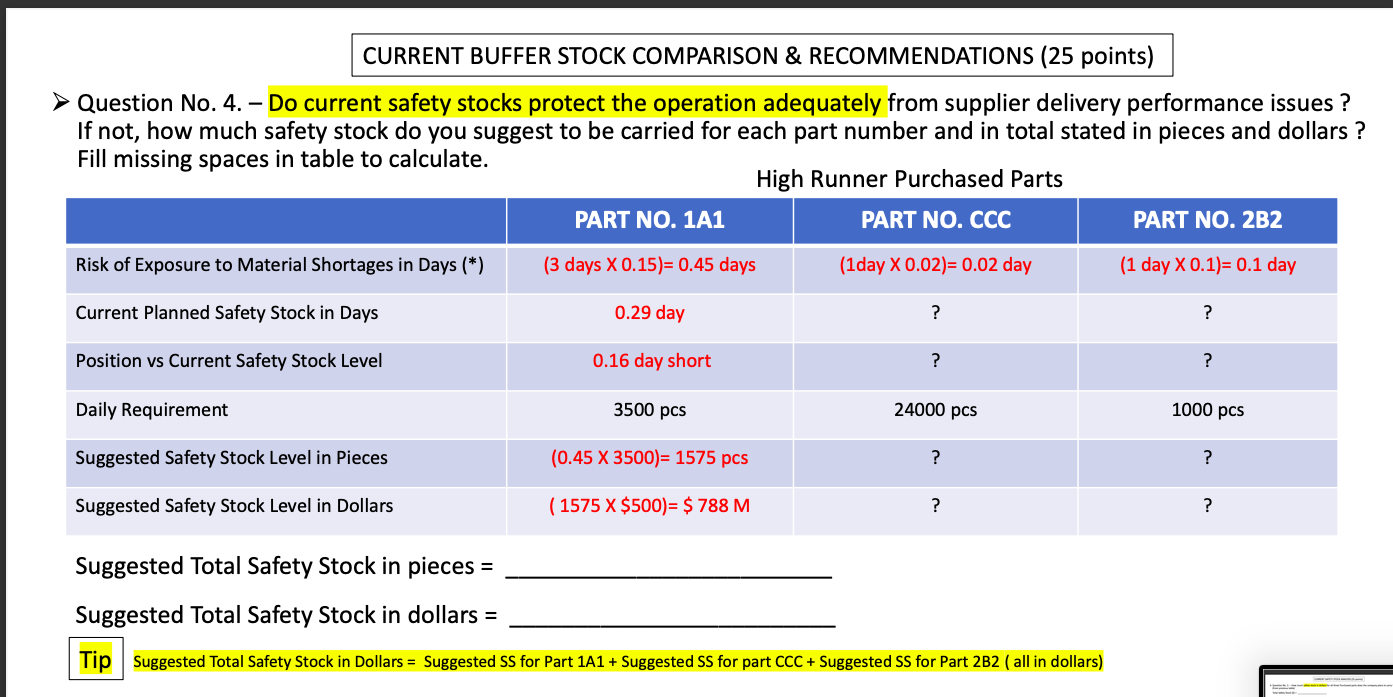

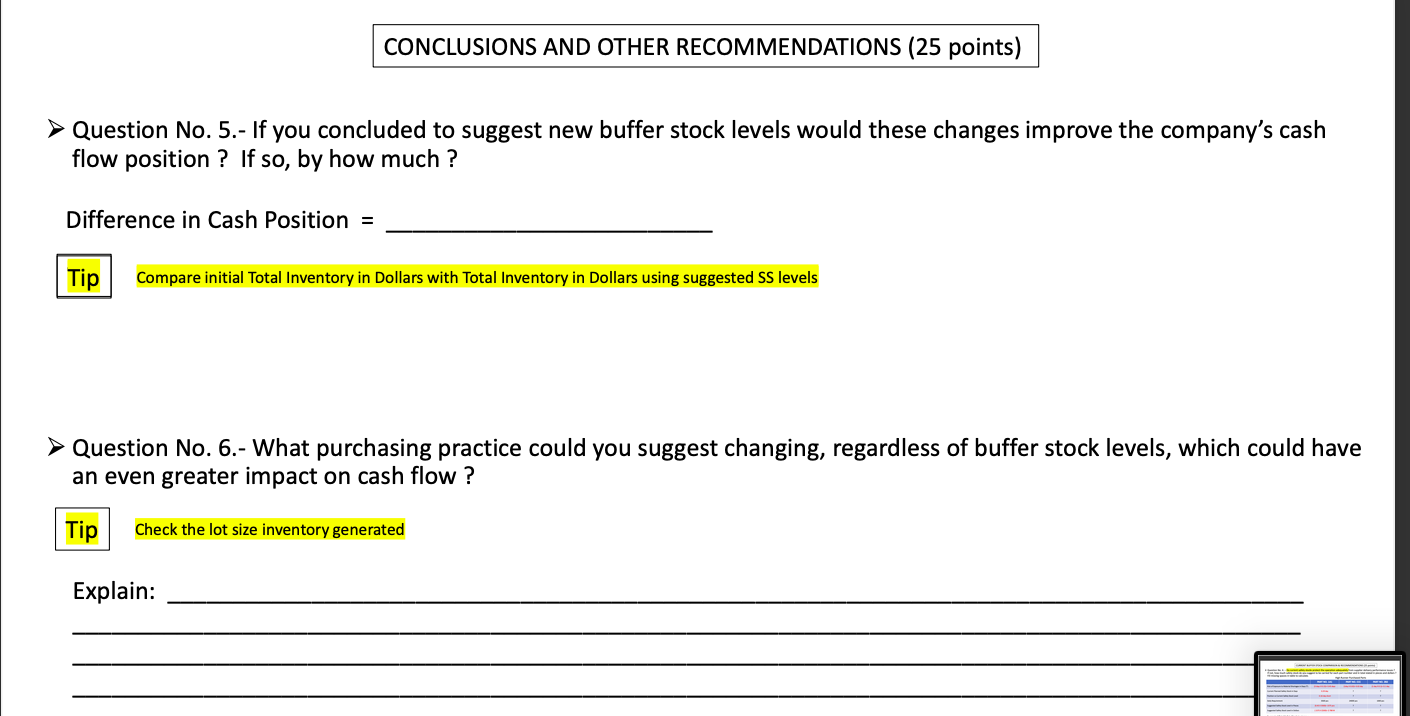

REPLENISHMENT & SAFETY STOCK STUDY CASE Consider the following scenario: The Supply Manager in a "widget" manufacturing company operating in a Make-To-Stock environment, decided to review its inventory position after a discussion with the company's Controller; who expressed that the company had way too much purchased material inventory and was negatively impacting the company's cash flow. The Supply Manager requested the Purchasing & Materials group to review the 3 highest dollar purchased items and verify their purchasing and inventory practices and if their safety stocks were properly set. Demand for these materials had been reasonably stable and was anticipated to continue that way. Purchasing placed orders for materials and components to suppliers to cover requirements on a weekly basis and the company operates in a 5-day week schedule. The Supply Manager's staff presented the following information. High Runner Purchased Parts PART NO. 1A1 PART NO. CCC PART NO. 2B2 Price per Unit $ 500 USD $ 25 USD $ 1800 USD Daily Requirements 3500 pcs 24000 pcs 1000 pcs Current Planned Safety Stock in Pcs 1000 pcs 60,000 pcs 1,000 pcs Current On-Hand Inventory in Pcs 1000 pcs 90,000 pcs 3000 pcs Providing Vendor Delivery Performance 85% of Orders On-Time 98% of Orders On-Time 90% of Orders On-Time Average Vendor Order Recovery when late in Days 3 1 1 Vendor Lead Time 10 working days 1 working days 5 working days ESTABLISHING THE CURRENT INVENTORY PLAN (25 points) Question No. 1. - What average inventory for each part number in pieces and dollars should the company have with current ordering practices (lot-size inventory) and planned buffer stock levels ? How much total average planned inventory should the company have on these three, part numbers? Fill in missing figures in table to calculate. PART NO. 1A1 PART NO. CCC PART NO. 2B2 Unit Price $ 500 $ 25 $ 1800 Order Qty ( Weekly Requirements) in Pieces 17,500 ? ? Average Inventory in Pieces (17,500/2) = 8,750 ? ? Average Inventory in Dollars (8,750 X $ 500) = $ 4,375,000 ? ? Current Planned Safety Stock in Pieces 1000 pcs 60,000 pcs 1,000 pcs Current Planned Safety Stock in Dollars (1000 x $ 500) = $ 500,000 ? ? Average Planned Inventory in Pieces 9,750 pcs ? ? Average Planned Inventory in Dollars ($ 4.375K + $ 500 K) = $ 4.875 K ? ? Tips For this study case consider the Average Inventory = Order Quantity/2 (could be in pieces or dollars) Total Avg. Planned Inventory (Pcs). Average Planned Inventory = Average Inventory + Safety Stock (could be in pieces or dollars) Total Avg. Planned Inventory ($). Total Average Planned Inventory in dollars = ($) Avg. Inv. Part 1A1+ ($) Avg. Inv. Part CCC + ($) Avg. Inv. Part 2B2 CURRENT SAFETY STOCK ANALYSIS (25 points) Question No. 2. How much safety stock in dollars for all three Purchased parts does the company plans to carry ? (from previous table) Total Safety Stock ($) = > Question No. 3. - How many days of safety stock for each part number does the company plans to carry ? How much total? Fill the missing spaces in the table to calculate. PART NO. 1A1 PART NO. CCC PART NO. 2B2 Current Planned Safety Stock in Dollars $ 500,000 ? ? Daily Usage in Dollars (3500 x $500) = $ 1,750,000 ? ? Days of Safety Stock ($500,000 / $1,750,000) = 0.29 days ? ? Total Safety Stock (days) Tip Days of Safety Stock = Current Planned Safety Stock in Dollars / Daily Usage in Dollars Total Safety Stock in days = SS for Part 1A1 + SS for Part CCC + SS for Part 2 CURRENT BUFFER STOCK COMPARISON & RECOMMENDATIONS (25 points) Question No. 4. - Do current safety stocks protect the operation adequately from supplier delivery performance issues ? If not, how much safety stock do you suggest to be carried for each part number and in total stated in pieces and dollars ? Fill missing spaces in table to calculate. High Runner Purchased Parts PART NO. 1A1 PART NO. CCC PART NO. 2B2 Risk of Exposure to Material Shortages in Days (*) (3 days X 0.15)= 0.45 days (1day X 0.02)= 0.02 day (1 day X 0.1)= 0.1 day Current Planned Safety Stock in Days 0.29 day ? ? Position vs Current Safety Stock Level 0.16 day short ? ? Daily Requirement 3500 pcs 24000 pcs 1000 pcs Suggested Safety Stock Level in Pieces (0.45 X 3500)= 1575 pcs ? ? Suggested Safety Stock Level in Dollars ( 1575 X $500)= $ 788 M ? ? Suggested Total Safety Stock in pieces = Suggested Total Safety Stock in dollars = Tip Suggested Total Safety Stock in Dollars = Suggested SS for Part 121 + Suggested SS for part CCC + Suggested SS for Part 2B2 ( all in dollars) CONCLUSIONS AND OTHER RECOMMENDATIONS (25 points) > Question No. 5.- If you concluded to suggest new buffer stock levels would these changes improve the company's cash flow position ? If so, by how much ? Difference in Cash Position = Tip Compare initial Total Inventory in Dollars with Total Inventory in Dollars using suggested SS levels Question No. 6.- What purchasing practice could you suggest changing, regardless of buffer stock levels, which could have an even greater impact on cash flow ? Tip Check the lot size inventory generated Explain