Question: Special Assignment Guidelines 2 0 2 4 - 0 3 The class assignment must include the following parts. a . Risk Breakdown Structure. The RBS

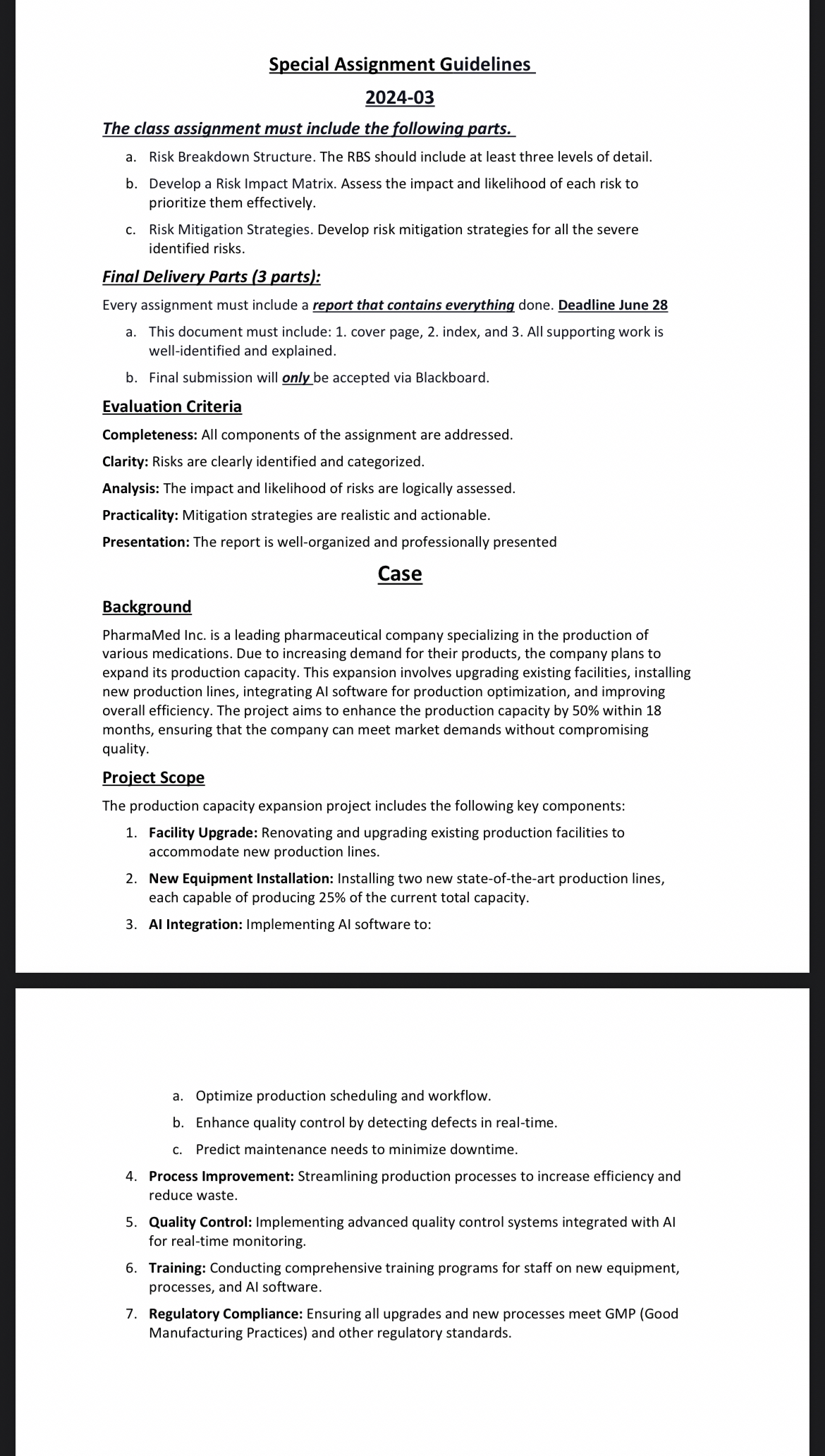

Special Assignment Guidelines

The class assignment must include the following parts.

a Risk Breakdown Structure. The RBS should include at least three levels of detail.

b Develop a Risk Impact Matrix. Assess the impact and likelihood of each risk to prioritize them effectively.

c Risk Mitigation Strategies. Develop risk mitigation strategies for all the severe identified risks.

Final Delivery Parts parts:

Every assignment must include a report that contains everything done. Deadline June

a This document must include: cover page, index, and All supporting work is wellidentified and explained.

b Final submission will only be accepted via Blackboard.

Evaluation Criteria

Completeness: All components of the assignment are addressed.

Clarity: Risks are clearly identified and categorized.

Analysis: The impact and likelihood of risks are logically assessed.

Practicality: Mitigation strategies are realistic and actionable.

Presentation: The report is wellorganized and professionally presented

Case

Background

PharmaMed Inc. is a leading pharmaceutical company specializing in the production of various medications. Due to increasing demand for their products, the company plans to expand its production capacity. This expansion involves upgrading existing facilities, installing new production lines, integrating Al software for production optimization, and improving overall efficiency. The project aims to enhance the production capacity by within months, ensuring that the company can meet market demands without compromising quality.

Project Scope

The production capacity expansion project includes the following key components:

Facility Upgrade: Renovating and upgrading existing production facilities to accommodate new production lines.

New Equipment Installation: Installing two new stateoftheart production lines, each capable of producing of the current total capacity.

Al Integration: Implementing Al software to:

a Optimize production scheduling and workflow.

b Enhance quality control by detecting defects in realtime.

c Predict maintenance needs to minimize downtime.

Process Improvement: Streamlining production processes to increase efficiency and reduce waste.

Quality Control: Implementing advanced quality control systems integrated with for realtime monitoring.

Training: Conducting comprehensive training programs for staff on new equipment, processes, and Al software.

Regulatory Compliance: Ensuring all upgrades and new processes meet GMP Good Manufacturing Practices and other regulatory standards.

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock