Question: standard MN % transmittance Unknown sample % transmittance 26 37 26.5 36.9 26 .8 37.1 concentration of MN standard sample is 0.6533%, length was 1.1cm

| standard MN % transmittance | Unknown sample % transmittance |

| 26 | 37 |

| 26.5 | 36.9 |

| 26 .8 | 37.1 |

concentration of MN standard sample is 0.6533%, length was 1.1cm

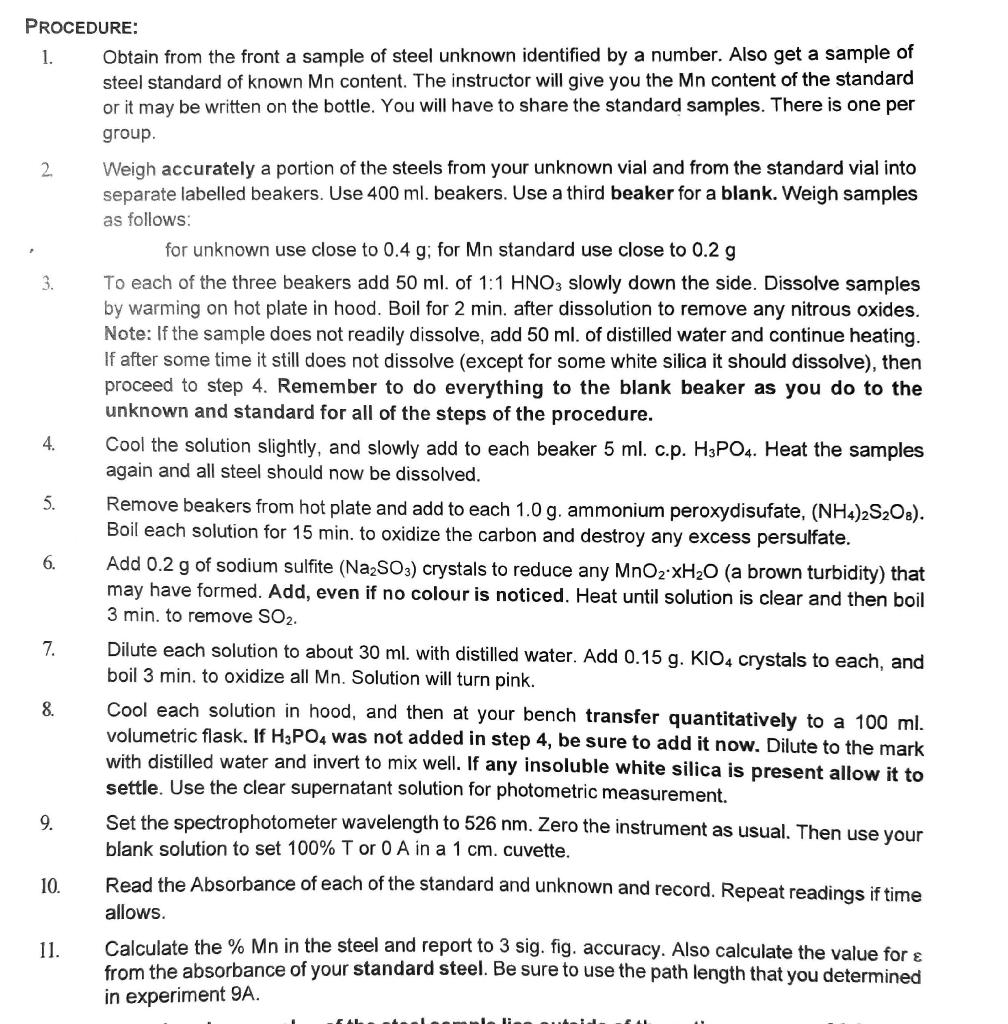

PROCEDURE: 1. Obtain from the front a sample of steel unknown identified by a number. Also get a sample of steel standard of known Mn content. The instructor will give you the Mn content of the standard or it may be written on the bottle. You will have to share the standard samples. There is one per group 2 Weigh accurately a portion of the steels from your unknown vial and from the standard vial into separate labelled beakers. Use 400 ml. beakers. Use a third beaker for a blank. Weigh samples as follows: for unknown use close to 0.4 g; for Mn standard use close to 0.2 g 3. To each of the three beakers add 50 ml. of 1:1 HNO3 slowly down the side. Dissolve samples by warming on hot plate in hood. Boil for 2 min. after dissolution to remove any nitrous oxides. Note: If the sample does not readily dissolve, add 50 ml. of distilled water and continue heating. If after some time it still does not dissolve (except for some white silica it should dissolve), then proceed to step 4. Remember to do everything to the blank beaker as you do to the unknown and standard for all of the steps of the procedure. 4. Cool the solution slightly, and slowly add to each beaker 5 ml. c.p. H3PO4. Heat the samples again and all steel should now be dissolved. 5. Remove beakers from hot plate and add to each 1.0 g. ammonium peroxydisufate, (NH4)2S208). Boil each solution for 15 min. to oxidize the carbon and destroy any excess persulfate. 6. Add 0.2 g of sodium sulfite (Na2SO3) crystals to reduce any MnO2-XH20 (a brown turbidity) that may have formed. Add, even if no colour is noticed. Heat until solution is clear and then boil 3 min. to remove SO2. 7. Dilute each solution to about 30 ml. with distilled water. Add 0.15 g. KIO4 crystals to each, and boil 3 min. to oxidize all Mn. Solution will turn pink. 8. Cool each solution in hood, and then at your bench transfer quantitatively to a 100 ml. volumetric flask. If H3PO4 was not added in step 4, be sure to add it now. Dilute to the mark with distilled water and invert to mix well. If any insoluble white silica is present allow it to settle. Use the clear supernatant solution for photometric measurement. 9. Set the spectrophotometer wavelength to 526 nm. Zero the instrument as usual. Then use your blank solution to set 100% T or 0 A in a 1 cm. cuvette. 10. Read the Absorbance of each of the standard and unknown and record. Repeat readings if time allows. 11. Calculate the % Mn in the steel and report to 3 sig. fig. accuracy. Also calculate the value for a from the absorbance of your standard steel. Be sure to use the path length that you determined in experiment 9A. PART A: Molar Extinction Coefficient for Mn (attach the calculation on a separate sheet) Use absorbance and concentration values from your standard steel sample Calculated value of a : (be sure to use correct units) Part B: Manganese by absorbance ratio method (attach calculations on a separate sheet) Unknown # Average Manganese concentration % (3 significant figures)

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts