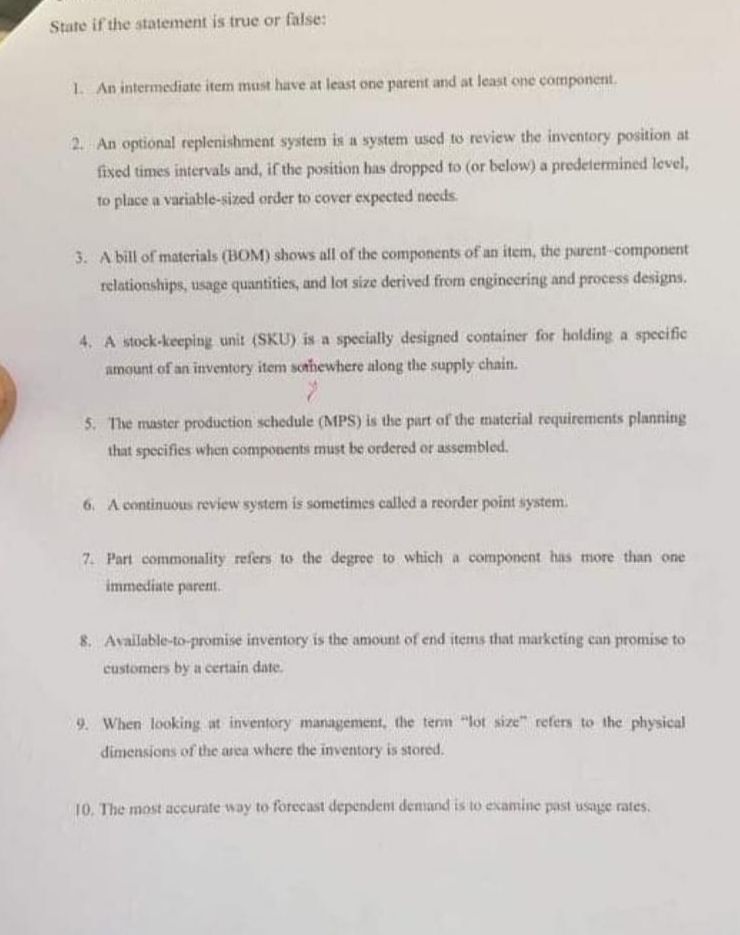

Stare if the statement is true or false:

An intermefiate item must have at least one parent and at least one component.

An optional replenishment system is a system used to review the inventory position at

fixed times intervals and, if the position has dropped to or below a predelermined level,

to place a variablesized order to cover expected needs.

A bill of materials BOM shows all of the components of an item, the purentcomponent

relationships, usage quantities, and lot size derived from enginecring and process designs.

A stockkeeping unit SKU is a specially designed container for holding a specific

amount of an inventory item sothewhere along the supply chain.

The master production schedule MPS is the part of the material requirements planning

that specifies when components must be ordered or assembled.

A continuous review system is sometimes called a reorder point system.

Part commonality refers to the degree to which a component has more than one

immediate parent.

Availabletopromise inventory is the amount of end items that marketing can promise to

customers by a certain date.

When looking at inventory management, the tern "lot size" refers to the physical

dimensions of the arca where the inventory is stored.

The most accurate way to forecast dependent demand is to examine past usage rates.