Question: Step 3 , The liquid is then filtered to remove the yeast and the ethanol is extracted by distillation to produce eight different types of

Step The liquid is then filtered to remove the yeast and the ethanol is extracted by

distillation to produce eight different types of ethanol for various industrial purposes.

For this assignment, we focus on the fermentation of whey.

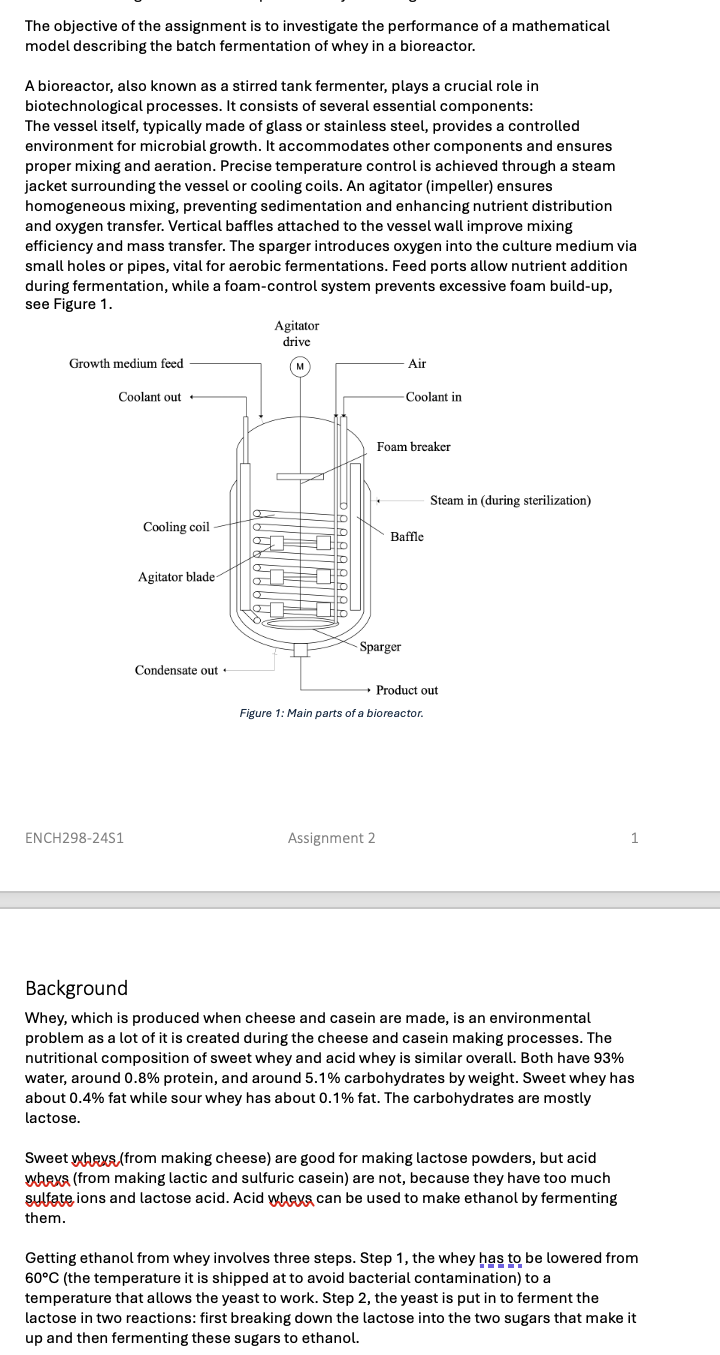

A mathematical model of a stirred tank fermenter is given by the system of ordinary

differential equations shown below. The feed or substrate, is used by the yeast to

make ethanol The yeast, or biomass, will grow and as a result will turn the sugars

into ethanol faster. The yeast will die over time and only the living yeast will keep

producing ethanol from lactose. The fermentation is a heatreleasing exothermic

reaction that increases the broth temperature Therefore the vessel has cooling coils

to lower the broth temperature. Equation and explain these processes.

The specific growth rate is dependent on the substrate concentration and the

ethanol concentration

where the maximum specific growth rate is temperature dependent

and the is the maximum product inhibition, the ethanol concentration hinders

the growth of the yeast

The yeast deactivation can be describe by

The substrate utilisation rate

The ethanol production rate

Equations and describe the energy balance around the bioreactor and its cooling

circuit. The heat generated by the fermentation increases the broth temperature

T The energy removed by the cooling circuit is depending on the

coolant's temperature entering the cooling circuit its flowrate the heat

transfer surface area and the heat transfer coefficient Where the term

represent the driving force between the coolant's temperature within the cooling circuit

and the broth temperature lowered from

the temperature it is shipped at to avoid bacterial contamination to a

temperature that allows the yeast to work. Step the yeast is put in to ferment the

lactose in two reactions: first breaking down the lactose into the two sugars that make it

up and then fermenting these sugars to ethanol.

SOLVE TASKS to USING PYTHON CODE

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock